Adhesive compositions and use thereof

A technology of adhesives and polymers, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of reduced heat resistance of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

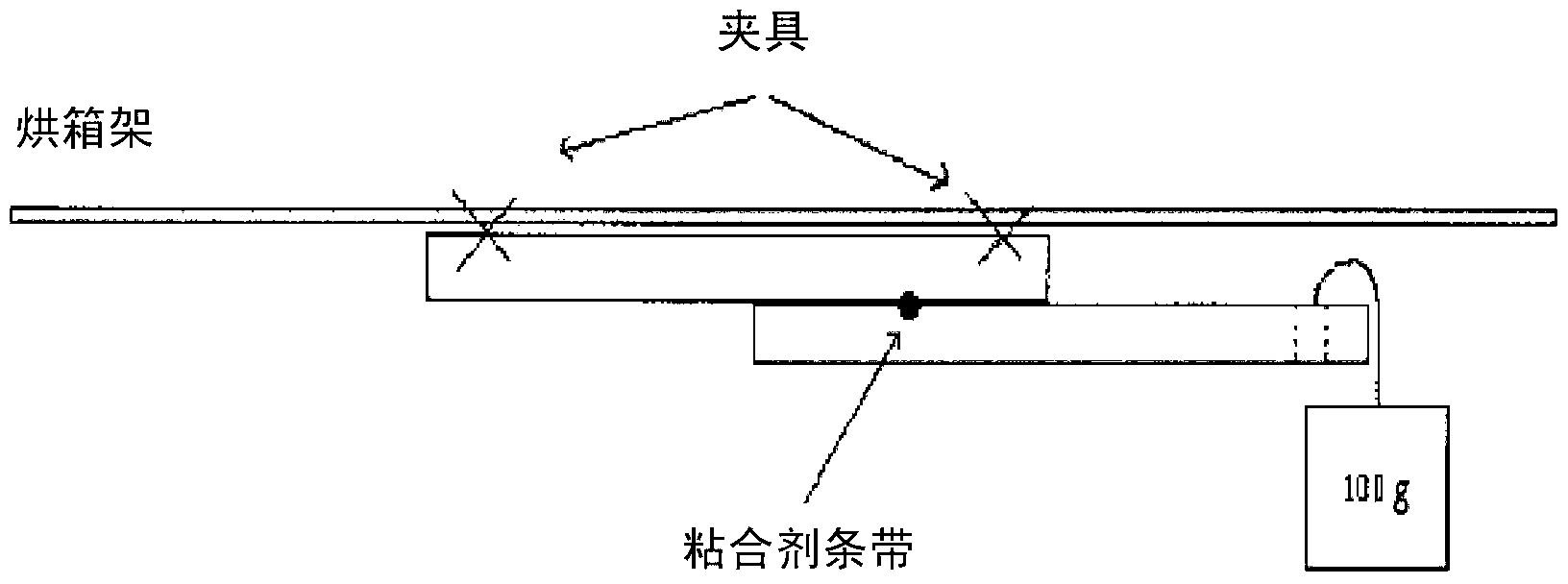

[0102] Thermal stress is defined as the temperature at which stress adhesion fails. The following thermal stresses or the ability of hot melts to withstand high temperatures under tearing forces (here also tear thermal stresses) are used in the examples to determine the heat resistance.

[0103] Values for heat resistance were determined as described in US 2009 / 0203847.

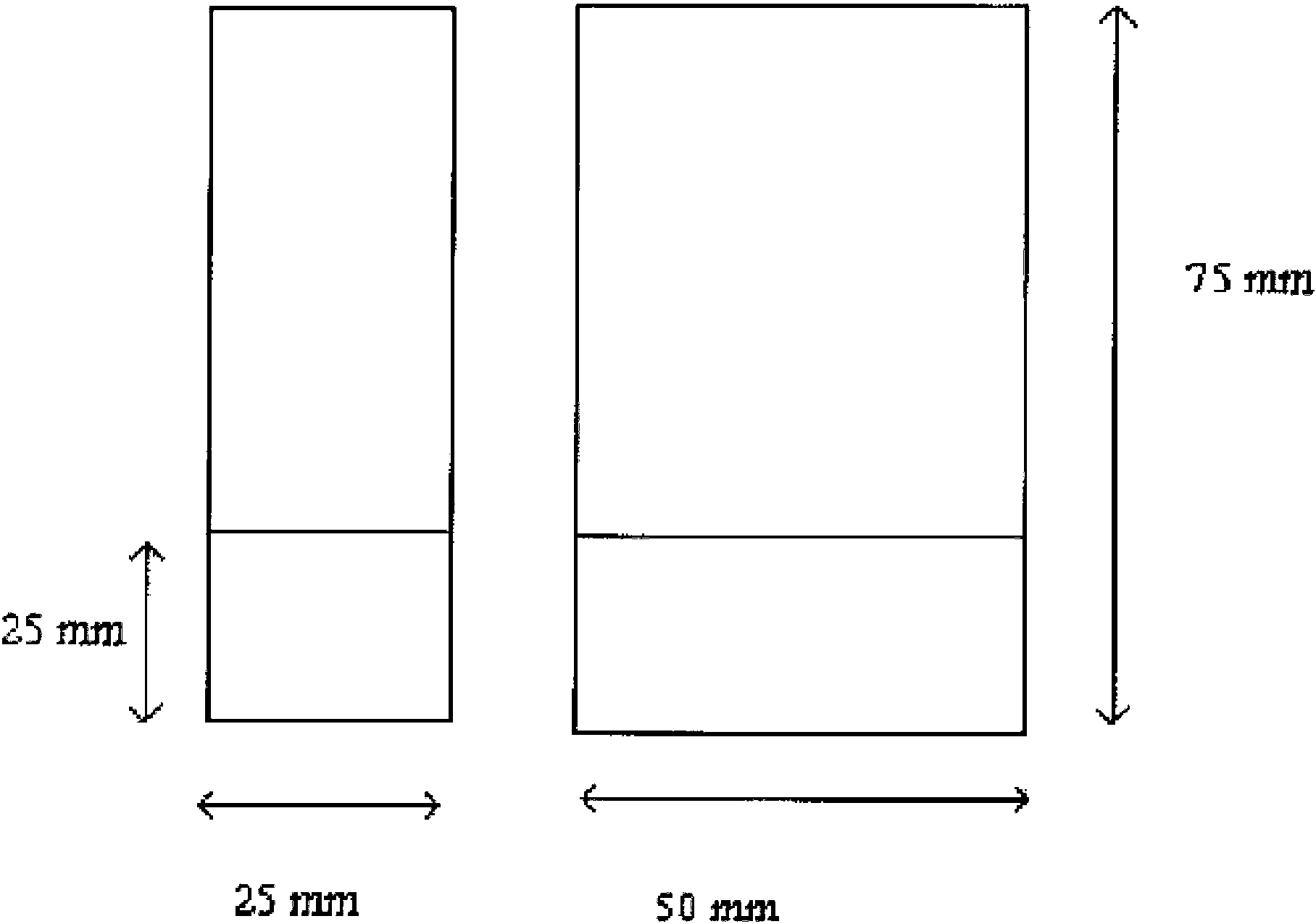

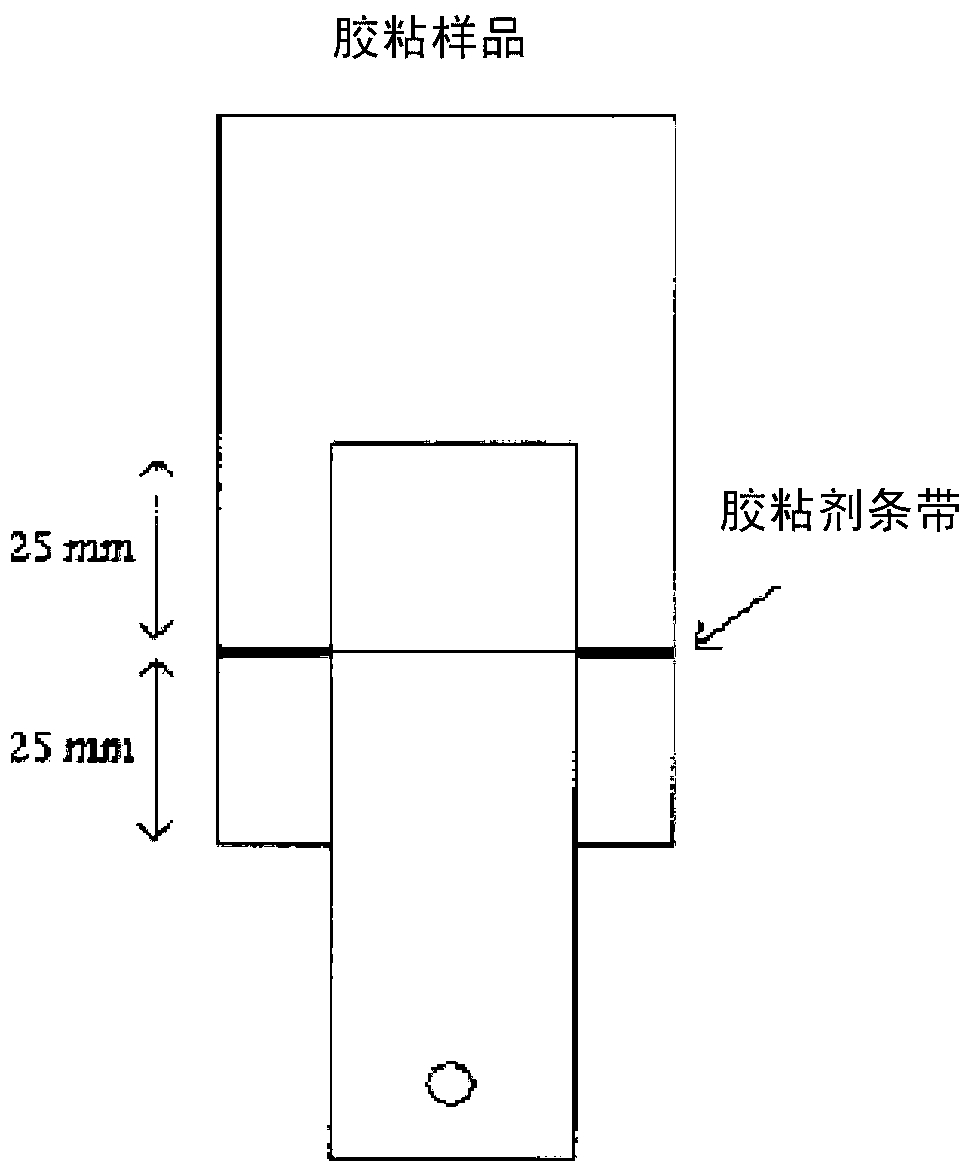

[0104] 1. Cut four pieces of cardboard 75mm x 25mm and 75mm x 50mm from corrugated cardboard with grooves parallel to the long sides. Draw a line 22mm from the end on both sides of each board, such as figure 1 shown in .

[0105] 2. Heat approximately 100 g of hot melt in a small metal container at an application temperature of 180°C - 185°C.

[0106] 3. Stir the adhesive with a spatula to ensure even heat distribution; then remove the spatula from the adhesive to create a stream of adhesive in the container. Repeat this method for each sample.

[0107] 4. Pass the 50mm board through the adhesive stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com