Adhesive composition for veneer sheets and preparation technique thereof

A technology of adhesives and compositions, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve problems such as production limitations, high pressure of hot-pressed thermometers, and production costs that cannot be greatly reduced , to achieve the effect of long service life and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

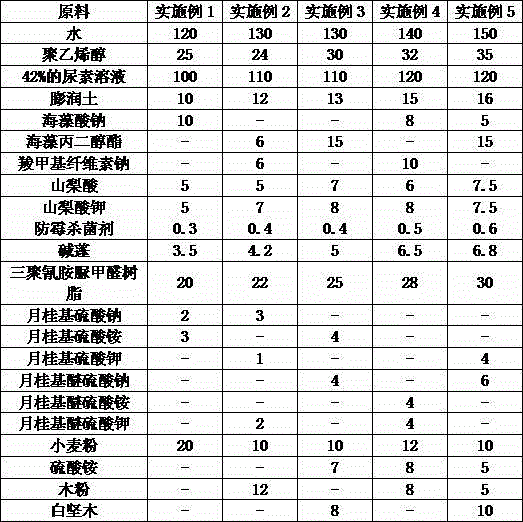

[0027] The preparation method includes the following steps: add water to the reaction kettle, heat to 45°C, slowly add polyvinyl alcohol while heating, raise the temperature to 95-100°C and stop heating after the polyvinyl alcohol is completely dissolved, keep the temperature for 1.5h, and cool down to 65°C Add melamine urea formaldehyde resin, 42% urea solution, bentonite, thickener, preservative, anti-mold and fungicide at ℃, after stirring for 30 minutes, add Suaeda salsa, filler, foaming agent, after mixing evenly, add acidity regulator, Adjust the pH value of the adhesive composition to 3-5.

[0028] Performance Testing:

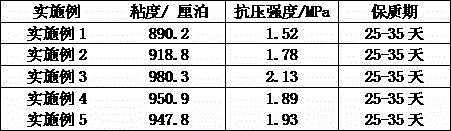

[0029] A viscometer bond strength test was performed on the adhesive composition for plywood prepared in Examples 1-5. The viscosity is measured by a rotational viscometer; the bond strength is expressed by the compressive strength that the soil mold can withstand, and is measured by an unconfined pressure instrument. The test environment, the tempe...

Embodiment 3

[0031] Embodiment 3 is the best implementation mode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com