Curable leak-stopping agent

A plugging agent and curing material technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult construction, narrow operating temperature range, reservoir damage, etc., and achieve little impact on drilling fluid performance, The construction process is simple and the effect of maintaining stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

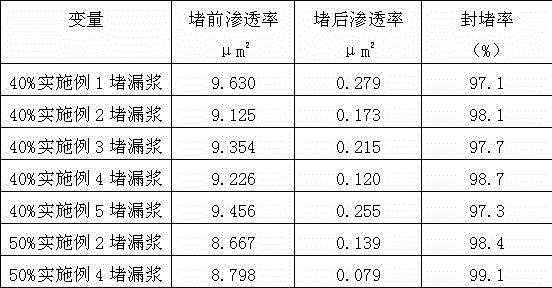

Examples

Embodiment 1

[0012] Put into the mixer 35 kg of curable blast furnace slag, 15 kg of high fluid loss material diatomite, 15 kg of fiber material asbestos fiber, 5 kg of flexible elastic expansion material elastic tire rubber, 30 kg of acid-soluble material calcium carbonate and mix evenly .

Embodiment 2

[0014] Put 45 kg of curable blast furnace slag into the mixer, 10 kg of fly ash as high filtration material, 20 kg of corn cob as fiber material, 2 kg of elastic tire rubber as soft elastic expansion material, and 23 kg of acid-soluble calcium carbonate and mix evenly .

Embodiment 3

[0016] Put 40 kg of curable material blast furnace slag into the mixer, 15 kg of high fluid loss material diatomite, 20 kg of fiber material corn cob, 2 kg of flexible elastic expansion material elastic tire rubber, 23 kg of acid-soluble material calcium carbonate and mix evenly .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com