New method for manufacturing paper-based micro-fluidic chip

A microfluidic chip and paper-based technology, applied to chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of increasing the production cost of paper chips, relying on professional operators, and limiting wide application, etc., to achieve Curing time is controllable, easy to expand, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

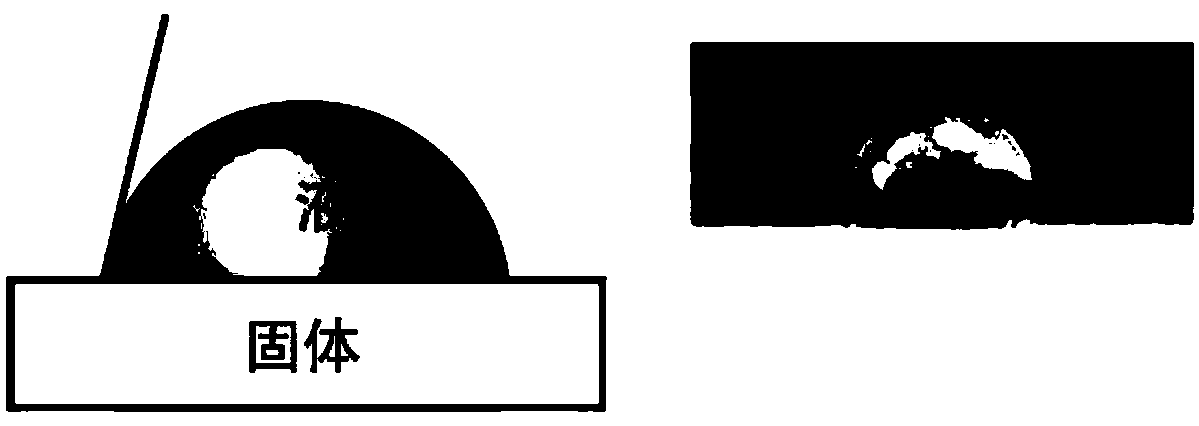

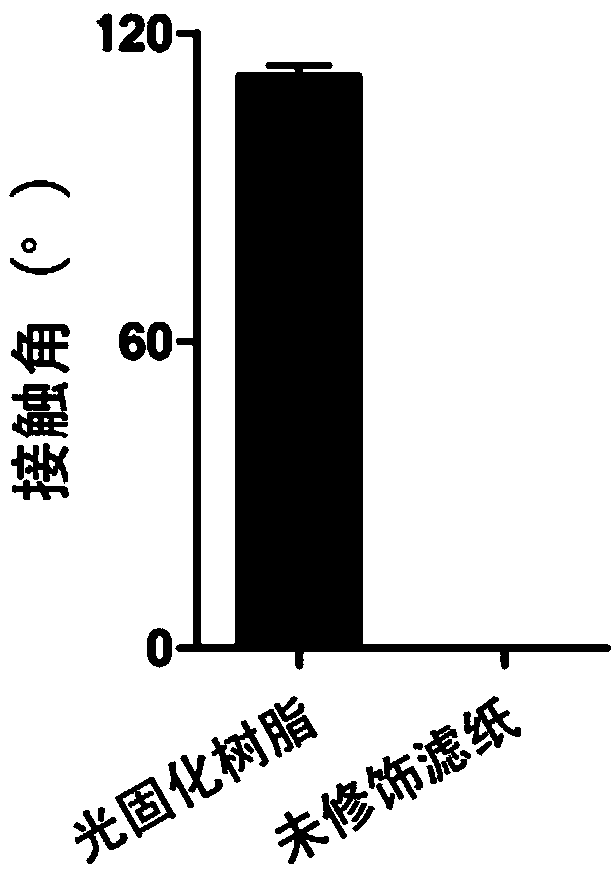

[0032] Example 1: Evaluation of hydrophobicity of photocurable resin coated on filter paper.

[0033] Use the photocurable resin mixture produced by IKONNA Company to evenly coat on Whatman1# qualitative filter paper, and light it under the ultraviolet LED light source for 3 minutes to polymerize and crosslink the photocurable resin monomer. Then spread the filter paper on the desktop, use a pipette gun to drop distilled water on the surface of the filter paper coated with photocurable resin, take pictures to record the shape of the water drop, and use graphic analysis software to process and calculate the contact angle between the water drop and the surface of the photocurable resin ( figure 1 ), and compared with unmodified filter paper. It is calculated that the contact angle between the water droplet and the surface of the photocurable resin is 112 ± 5°, and the water droplet is completely wetted and absorbed immediately after falling onto the surface of the unmodified fil...

Embodiment 2

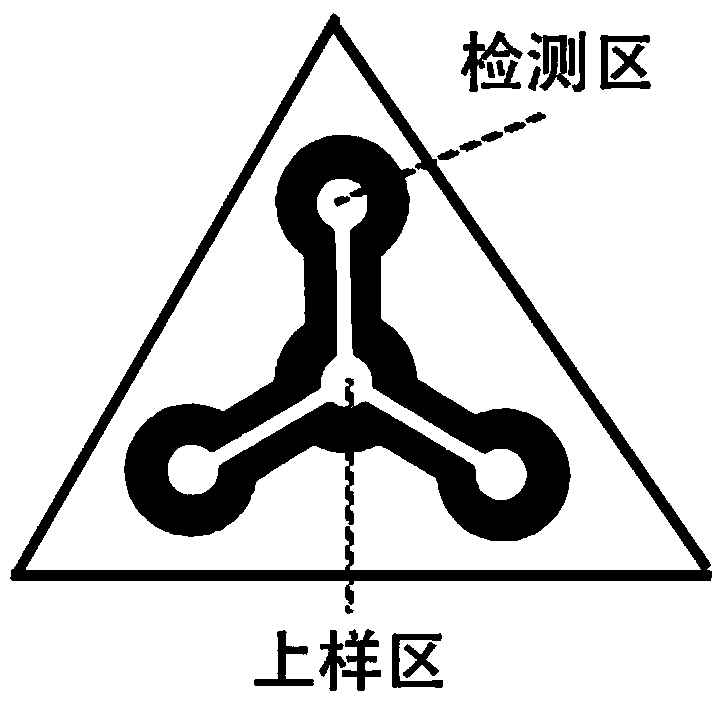

[0034] Example 2: Fabrication of a paper-based microfluidic chip using photocurable resin and stamp technology.

[0035] According to the purpose of the chip, design a three-channel microfluidic chip. Engraving and making red plastic seals, the seal pattern is as follows image 3 shown. The side length of the triangle is 3.8 centimeters (cm), the width of the edge protrusions of the three straight channels is 1.5 mm (mm), the width of the edge protrusions of the three detection areas is 1.5 mm, and the width of the edge protrusions of the central sample loading area is 2.25 mm. mm. Use the stamp to print the photocurable resin on the filter paper. The channel size of the formed microfluidic chip is: the width of the three straight channels is 1.5mm, the length is 8mm, the diameter of the central sample area is 3.5mm, and the diameter of the three detection areas 3.5mm. Under the ultraviolet LED light source for 3 minutes, the photocurable resin monomer is polymerized and c...

Embodiment 3

[0036] Example 3: A paper-based microfluidic chip fabricated using photocurable resin and stamp technology is used for the quantitative detection of proteins and heavy metal ions.

[0037] Use bovine serum albumin to prepare a series of protein solutions with concentrations of 6.25, 12.50, 18.75, 25.00, and 31.25 micromole per liter (μM), and use zinc chloride to prepare a series of protein solutions with concentrations of 1, 2, 4, 6, and 8 micrograms per Milliliters (μg / mL) of zinc ion solution. A paper-based microfluidic chip was fabricated using a mixture of qualitative filter paper and photocurable resin to detect the concentration of protein and zinc ions. Add bromophenol blue dropwise to one detection area of the chip, and add zinc ion indicator dropwise to the other detection area of the chip. Add 20 microliters of protein solution dropwise to the sample loading area, use the mobile phone software Color Assist to read the RGB value of the detection area after the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com