3D printing sprayer

A 3D printing and nozzle technology, applied in the field of 3D printing nozzles, can solve the problems of high cost, high use and maintenance costs of photo-curing printing systems, achieve controllable curing time, avoid high costs, and solve the effect of curing after printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

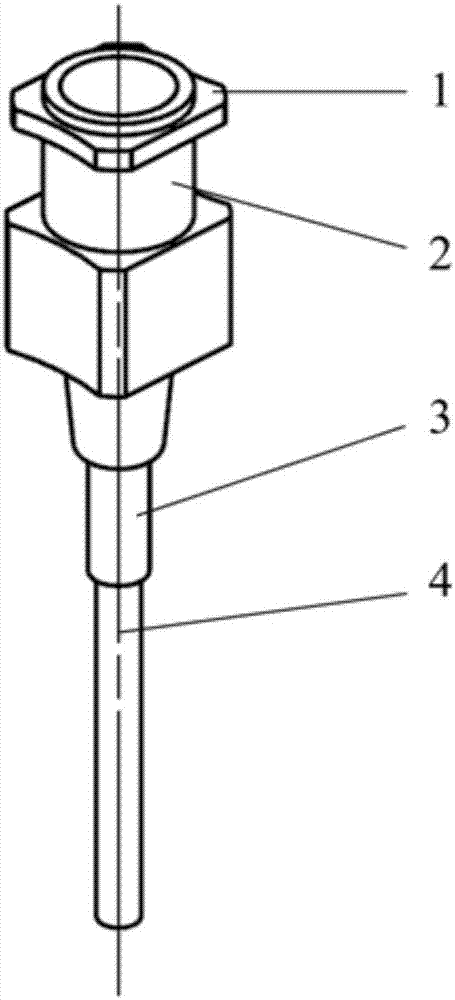

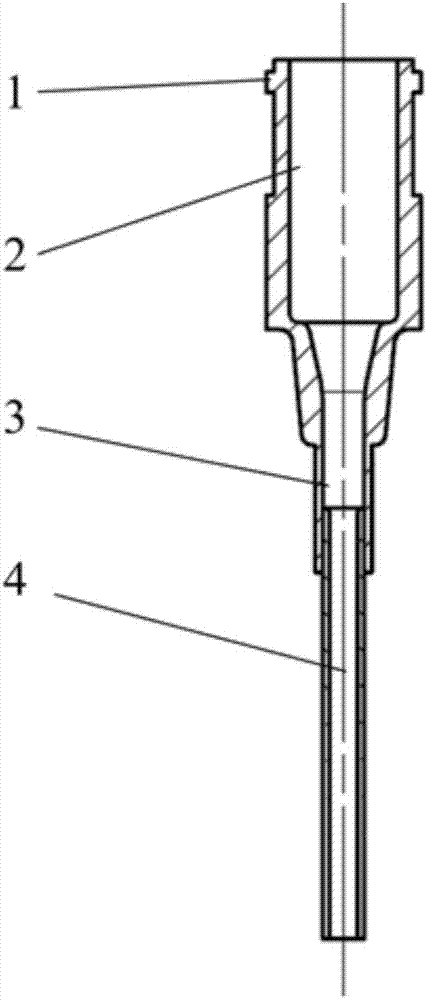

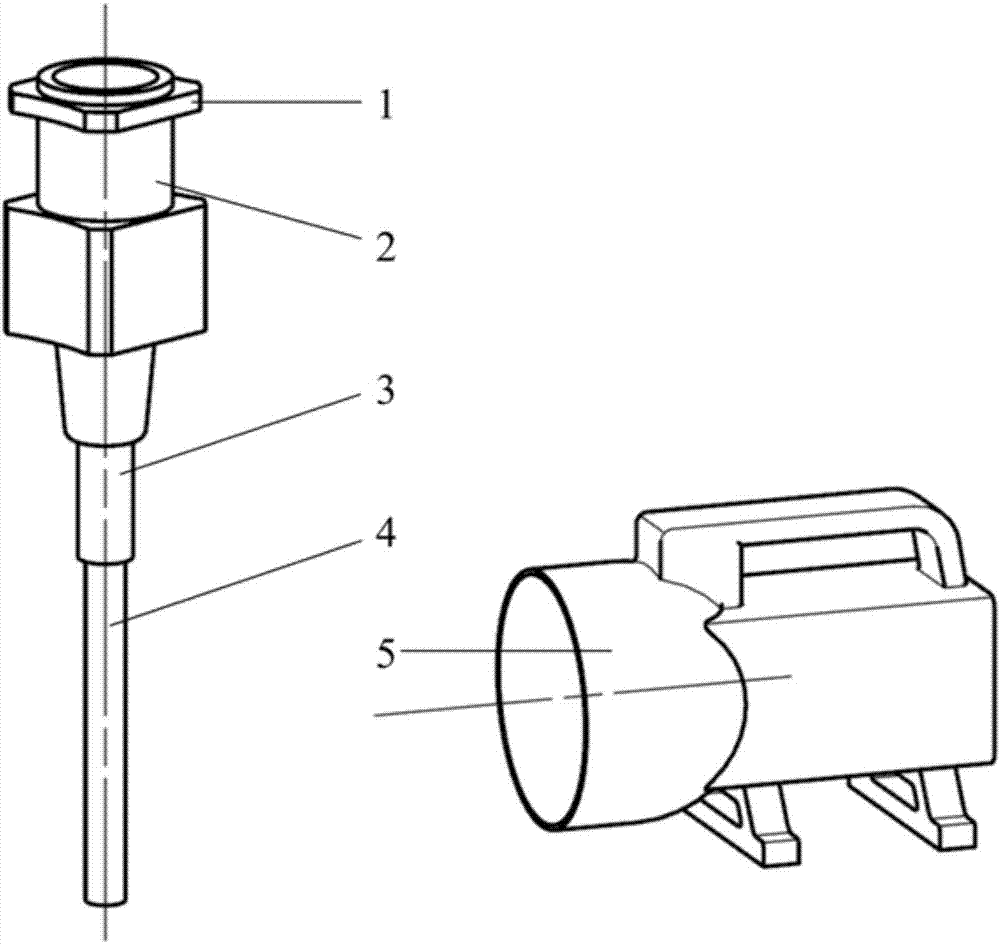

[0030] like Figure 1a and Figure 1b As shown, a 3D printing nozzle structure includes a connecting seat 1 , a feed liquid storage pipe 2 , an opaque injection head 3 , and a light-transmissive injection head 4 .

[0031] like Figure 1a and Figure 1b As shown, the top of the print nozzle is a connecting seat 1 , the bottom of the connecting seat 1 is connected to the feeding liquid storage pipe 2 , and the connecting seat 1 communicates with the inner cavity of the feeding liquid storing pipe 2 . At the same time, the connection base 1 and the feeding liquid storage pipe 2 are connecting bodies, which are provided with connection structures such as connection grooves, connection ears, connection threads, connection holes, connection clips, etc., to facilitate the assembly of the nozzle structure on the printer.

[0032]The light-tight injection head 3 and the light-transmissible injection head 4 are connected into one body, and the inner cavities of the two injection heads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com