Organic-inorganic hybrid cross-linked heat-conducting silica gel and preparation method thereof

A heat-conducting silica gel, hybrid cross-linking technology, applied in the field of heat-conducting materials, can solve the problem of low thermal conductivity of the system as a whole, and achieve the effects of excellent thermal conductivity, good mechanical properties, and suitable operating viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

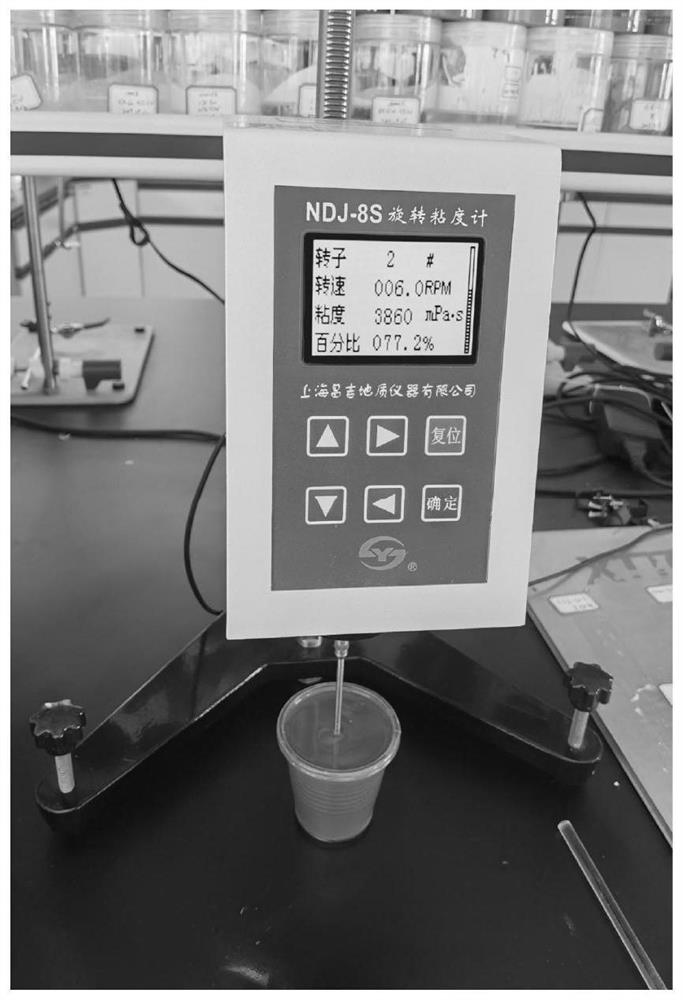

Image

Examples

Embodiment 1

[0042] The mass proportion of each component in this example is: vinyl silicone oil 29.7%, hydrogen-containing silicone oil 5.4%, dimethyl silicone oil 4.34%, chemically modified inorganic thermally conductive filler 41.59%, copper powder 17.82%, white carbon black 0.96% %, graphene 0.15%, catalyst 0.03%, inhibitor 0.0075%, wherein the inorganic filler to be modified adopts alumina, and the mass ratio of the coupling agent to the inorganic filler to be modified is 0.02:1.

[0043] The organic-inorganic hybrid cross-linked thermally conductive silica gel is prepared by using the components listed above in terms of mass proportion, and the specific steps are as follows:

[0044] S1a. Weigh 80g of deionized water into an Erlenmeyer flask, place it in a constant temperature water bath for stirring, add 2.4g of KH570 dropwise to it, heat and stir it in a constant temperature water bath at 60°C for 2 hours after adding it completely, and then gradually add 120g of alumina to be modi...

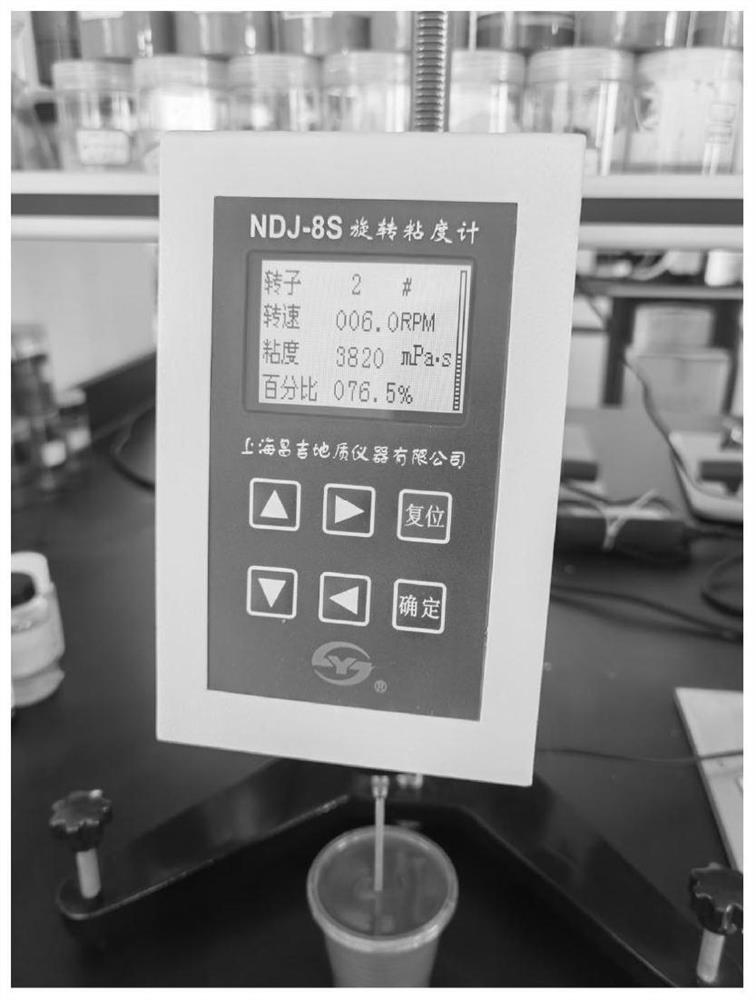

Embodiment 2

[0048] The mass proportion of each component in this example is: vinyl silicone oil 29.7%, hydrogen-containing silicone oil 5.4%, dimethyl silicone oil 4.34%, chemically modified inorganic thermally conductive filler 41.59%, copper powder 17.82%, white carbon black 0.96% %, graphene 0.15%, catalyst 0.03%, and inhibitor 0.0075%, wherein the inorganic filler to be modified is alumina, and the mass ratio of the coupling agent to the inorganic filler to be modified is 0.05:1.

[0049] The organic-inorganic hybrid cross-linked thermally conductive silica gel is prepared by using the components listed above in terms of mass proportion, and the specific steps are as follows:

[0050] S1a. Weigh 80g of deionized water into an Erlenmeyer flask, place it in a constant temperature water bath for stirring, add 2.4g of KH570 dropwise to it, heat and stir it in a constant temperature water bath at 60°C for 2 hours after adding it completely, and then gradually add 48g of alumina to be modif...

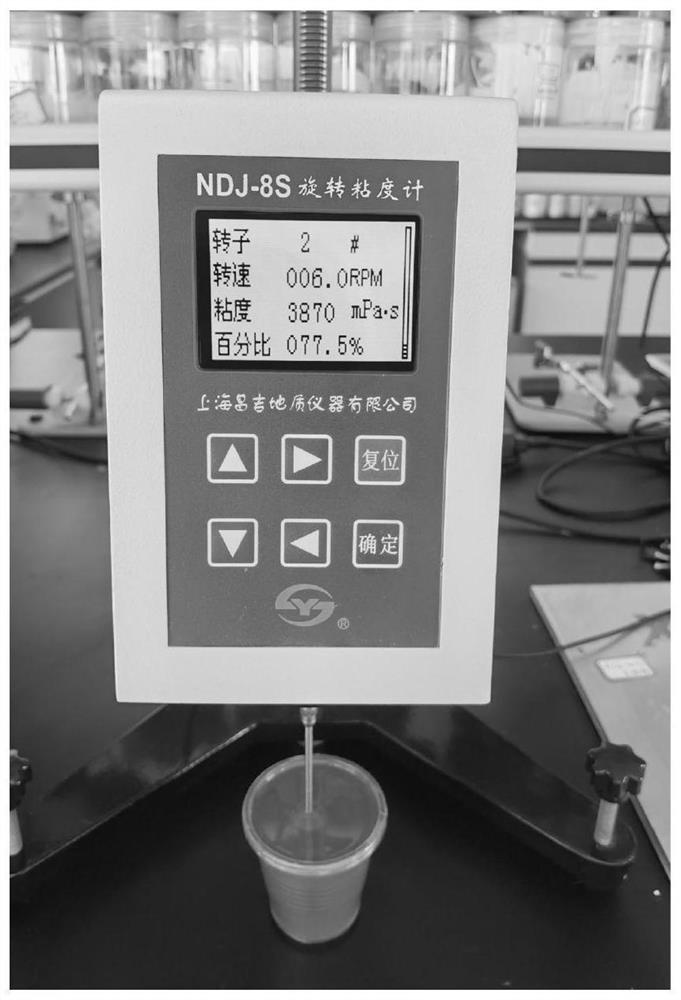

Embodiment 3

[0054] The mass proportion of each component in this example is: vinyl silicone oil 29.7%, hydrogen-containing silicone oil 5.4%, dimethyl silicone oil 4.34%, chemically modified inorganic thermally conductive filler 41.59%, copper powder 17.82%, white carbon black 0.96% %, graphene 0.15%, catalyst 0.03%, inhibitor 0.0075%, wherein the inorganic filler to be modified adopts alumina, and the mass ratio of the coupling agent to the inorganic filler to be modified is 0.035:1.

[0055] The organic-inorganic hybrid cross-linked thermally conductive silica gel is prepared by using the components listed above in terms of mass proportion, and the specific steps are as follows:

[0056] S1a. Weigh 80g of deionized water into an Erlenmeyer flask, place it in a constant temperature water bath for stirring, add 2.4g of KH570 dropwise to it, heat and stir it in a constant temperature water bath at 60°C for 2 hours after adding it completely, and then gradually add 68.57g of alumina to be m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com