Heavy oil thermal recovery high-temperature channeling blocking composite plugging-adjusting liquid and preparing method and application thereof

A heavy oil thermal recovery and high temperature technology, applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve problems affecting oil well production, high injection pressure, lack of adaptability, etc., to achieve controllable solidification time, Strong high temperature resistance, avoiding the effect of repeated operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

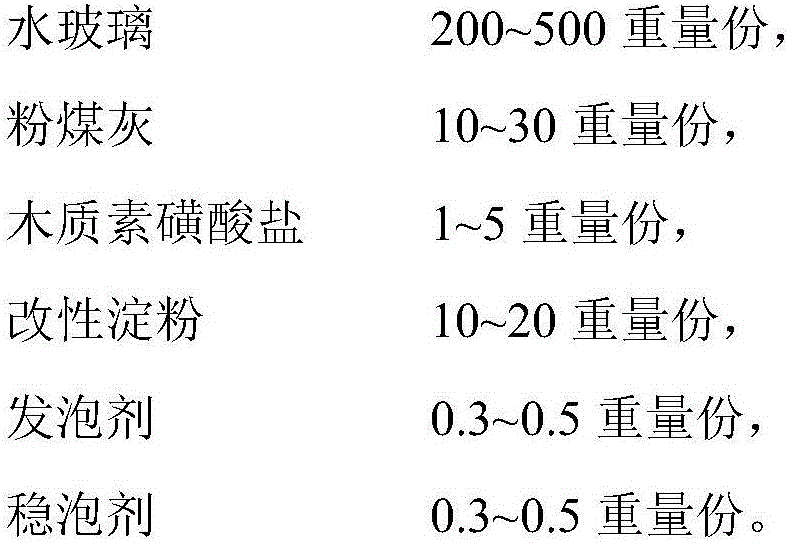

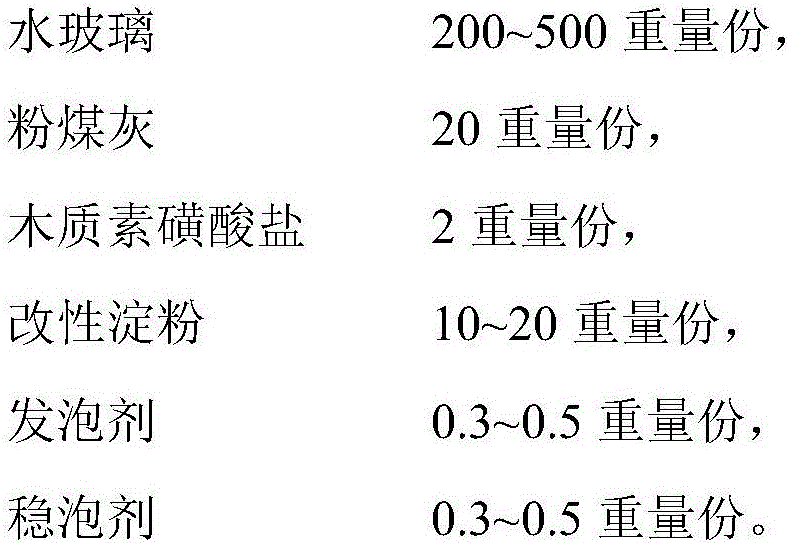

Method used

Image

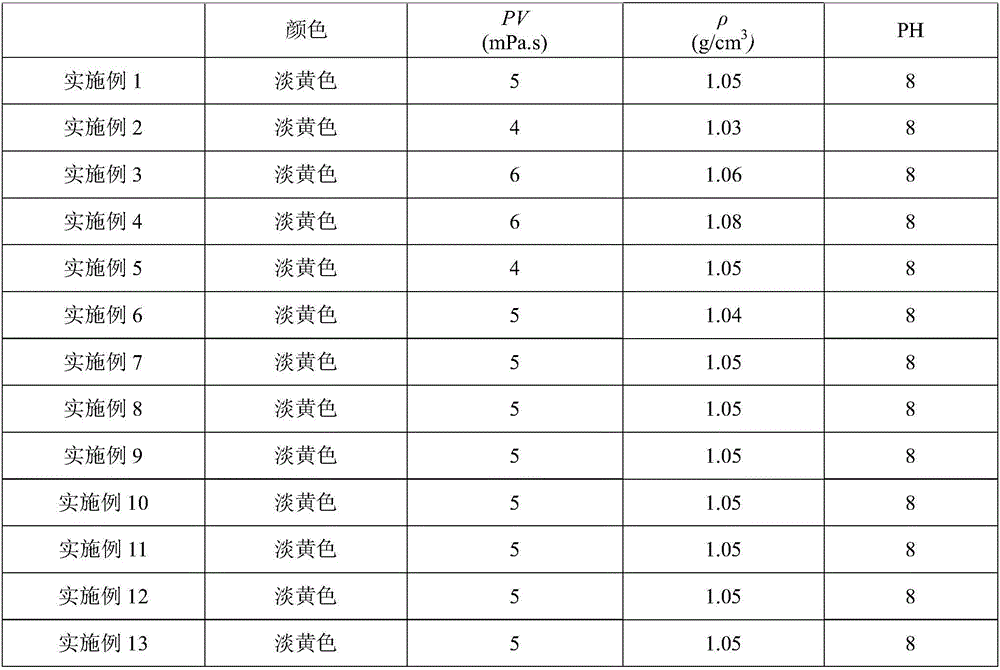

Examples

Embodiment 1

[0037] Weigh 1000g of water, add the density of 1.35g / cm 3 Sodium silicate 200g, fly ash 20g, calcium lignosulfonate 2g, modified starch 10g, foaming agent BZ-MBS-1 0.3g, foam stabilizer BZ-MBSF-1 0.3g, shear at 3000rpm Stir for 20 minutes to obtain the finished product.

Embodiment 2

[0039] Weigh 1000g of water, add the density of 1.42g / cm 3 Potassium silicate 250g, fly ash 10g, sodium lignin sulfonate 1g, modified starch 20g, foaming agent BZ-MBS-1 0.5g, foam stabilizer BZ-MBSF-1 0.5g, shear at 3500rpm Stir for 20 minutes to obtain the finished product.

Embodiment 3

[0041] Weigh 1000g of water, add the density of 1.40g / cm 3 Lithium water glass 300g, fly ash 30g, calcium lignosulfonate 5g, modified starch 15g, foaming agent BZ-MBS-1 0.4g, foam stabilizer BZ-MBSF-1 0.4g, shearing at 3800rpm Stir for 20 minutes to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com