Preparation method of magnesium phosphate medical bone adhesive

A technology of bone cement and magnesium phosphate, applied in chemical instruments and methods, applications, medical science and other directions, can solve the problem of low bonding strength of magnesium phosphate medical bone cement, and achieve controllable curing time and mechanical properties. Good, low exothermic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of magnesium phosphate medical bone cement of the present invention is specifically implemented according to the following steps:

[0027] Step 1, first put the medical grade MgO in the crucible, then place the MgO and the crucible together in an energy-saving rapid heating resistance furnace, and calcinate the MgO at a high temperature at a calcination temperature of 1300-1600°C, and keep the temperature for 3-6 hours. Then dry-grind and pulverize in a planetary ball mill to a powder with a particle size of 0-20 μm;

[0028] Step 2, the KH 2 PO 4 Place it in a drying oven at a drying temperature of 120°C for more than 24 hours, then dry grind it in a planetary ball mill to a powder with a particle size of 0-20 μm;

[0029] Step 3, the additive is prepared into a dilute solution with a concentration of 1.0-10.0% and stirred evenly to obtain a solid-phase blended solution A, the solvent is deionized water, normal saline, glucose solution or a dil...

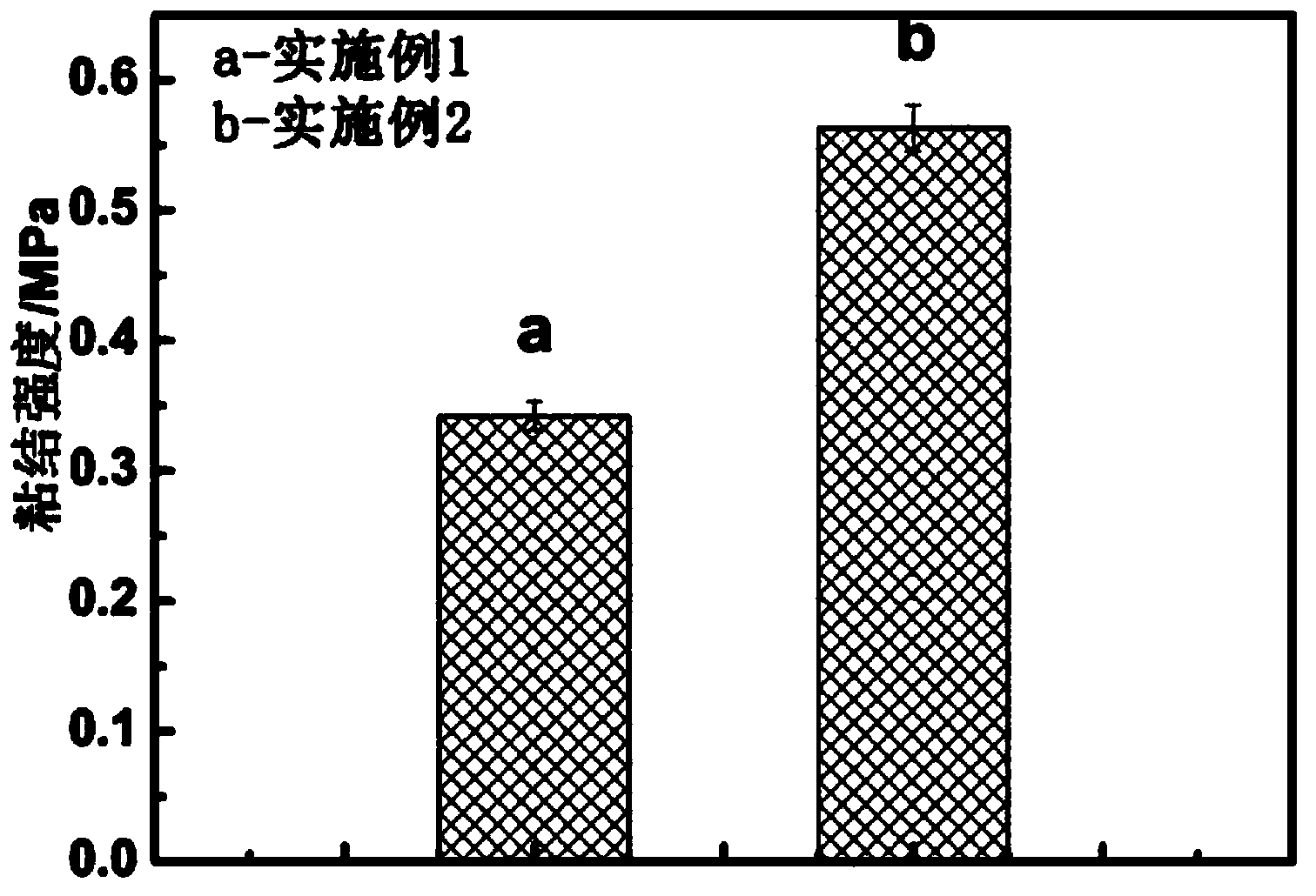

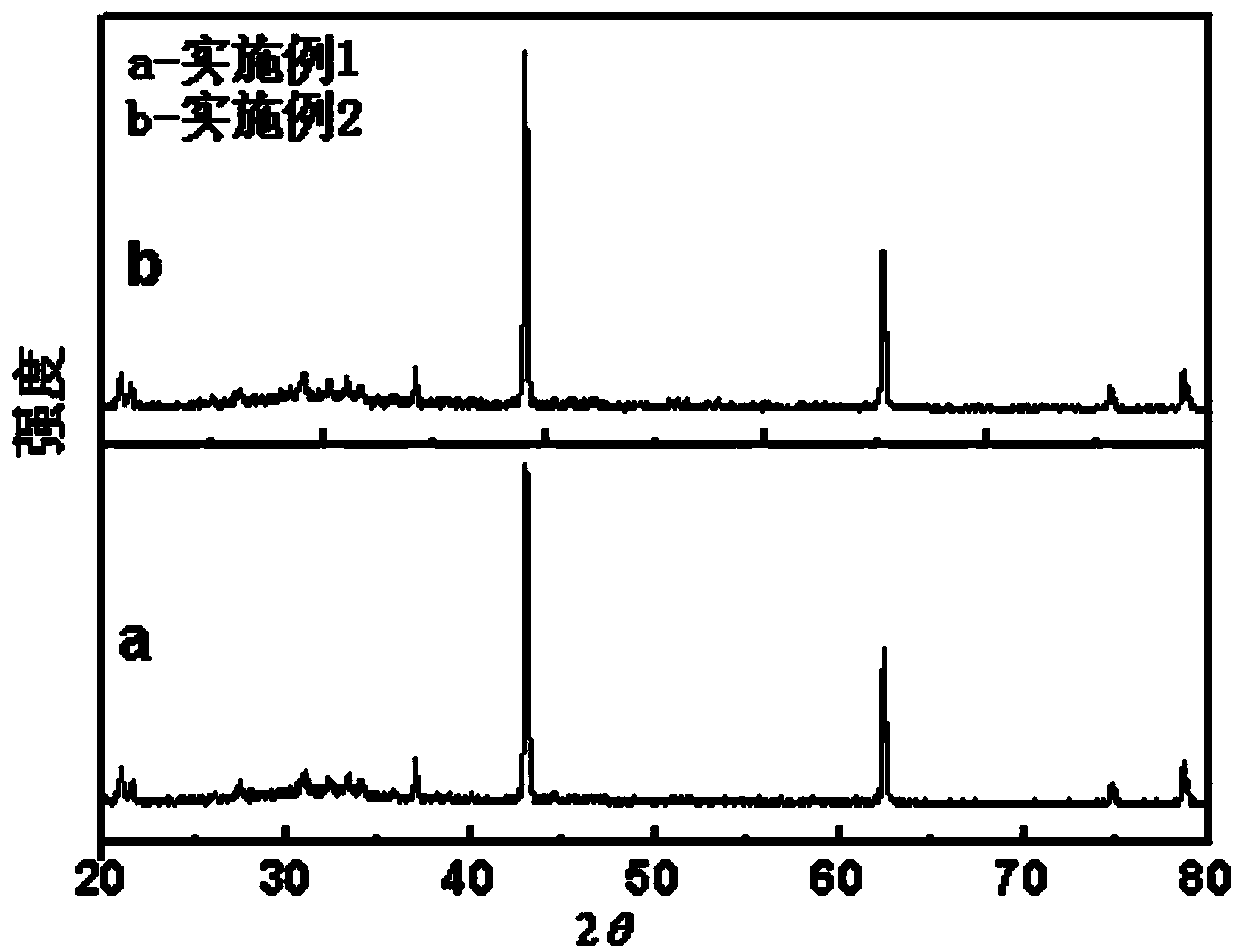

Embodiment 1

[0034] The preparation method of existing magnesium phosphate medical bone cement, concrete steps are as follows:

[0035] Step 1, first put the medical grade MgO in the crucible, then put the MgO and the crucible together in an energy-saving fast heating resistance furnace, calcinate the MgO at a high temperature of 1500°C, keep it warm for 3 hours, and then use the planetary type Ball mill dry grinding to powder with a particle size of 10 μm;

[0036] Step 2, the KH 2 PO 4 Place in a drying oven at a drying temperature of 120°C, dry for 24 hours, and then use a planetary ball mill to dry grind to a powder with a particle size of 20 μm;

[0037] Step 3, mix the MgO powder obtained in step 1 with the KH obtained in step 2 2 PO 4 The powders are mixed evenly to obtain mixture A, wherein, MgO powder and KH 2 PO 4 The substance ratio of the powder is 5:1; then add deionized water to the mixture A while stirring to obtain the slurry B, wherein the mass ratio of the mixture A...

Embodiment 2

[0039] Step 1, first put the medical grade MgO in the crucible, then put the MgO and the crucible together in an energy-saving fast heating resistance furnace, calcinate the MgO at a high temperature of 1500°C, keep it warm for 3 hours, and then use the planetary type Ball mill dry grinding to powder with a particle size of 10 μm;

[0040] Step 2, the KH 2 PO 4 Place in a drying oven at a drying temperature of 120°C, dry for 24 hours, and then use a planetary ball mill to dry grind to a powder with a particle size of 20 μm;

[0041] Step 3, mixing lactic acid and deionized water to prepare a dilute solution with a concentration of 1.0% and stirring evenly to obtain a solid-phase blended solution A;

[0042] Step 4, the MgO powder obtained in step 1 and the KH obtained in step 2 2 PO 4 Mix the powder evenly to obtain mixture B, in which, MgO powder and KH 2 PO 4 The substance ratio of the powder is 5:1; then add the solid phase blending liquid A to the mixture B while sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com