Novel solar battery backboard

A kind of technology of solar cell and back sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

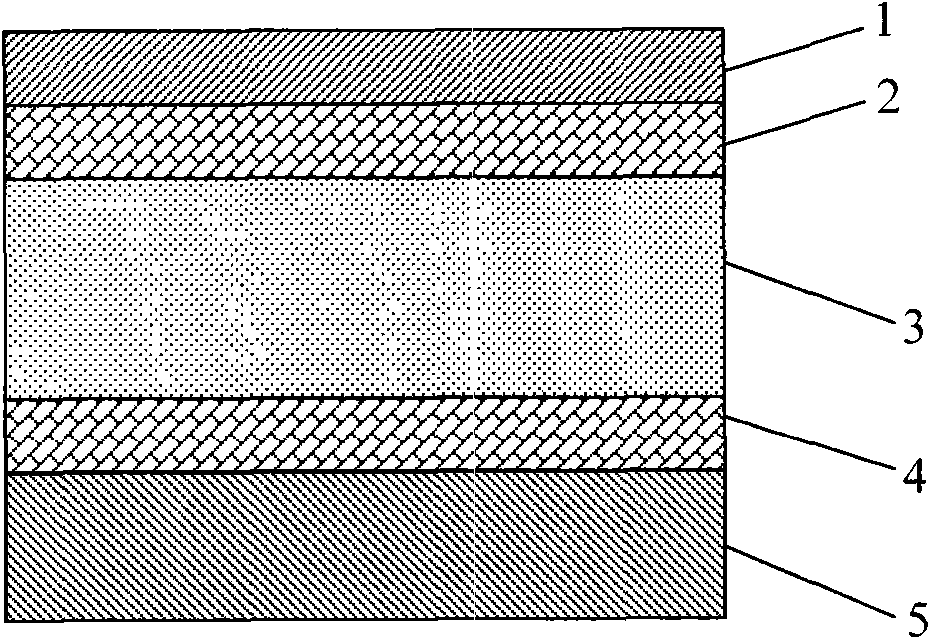

[0028] See figure 1 As shown, the novel solar battery back sheet of the present invention includes a weather-resistant layer 1, a first adhesive layer 2, a structural reinforcement layer 3, a second adhesive layer 4 and an adhesive reflective layer 5, and the weather-resistant layer 1 passes through the The first adhesive layer 2 is bonded to the structural reinforcement layer 3, the structural reinforcement layer 3 is bonded to the adhesive reflective layer 5 through the second bonding layer 4, and the weather-resistant layer 1 is modified by inorganic materials. The polyvinylidene fluoride (PVDF) alloy layer, and the adhesive reflective layer 5 is a white polyethylene (PE) layer.

[0029] Preferably, the polyvinylidene fluoride alloy layer is a blended plastic alloy layer of polyvinylidene fluoride and inorganic materials.

[0030] More p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com