Preparation method for high strength solventless epoxy adhesive

An epoxy adhesive, solvent-free technology, applied in the direction of modified epoxy resin adhesive, etc., can solve the problems of not meeting high temperature conditions, endangering human health, poor processability, etc., achieving low cost and convenient operation , Excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

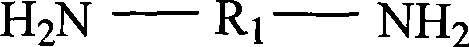

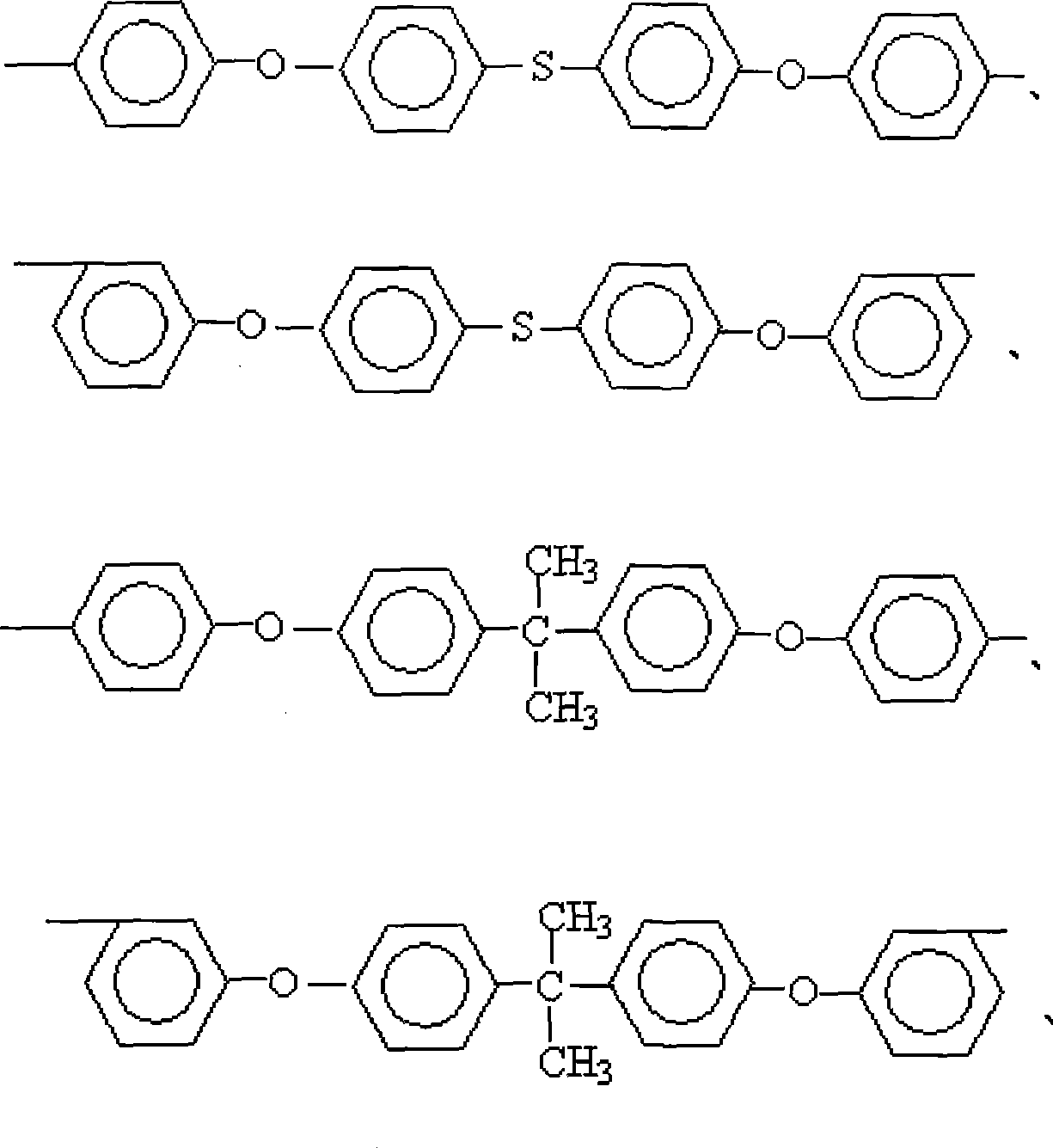

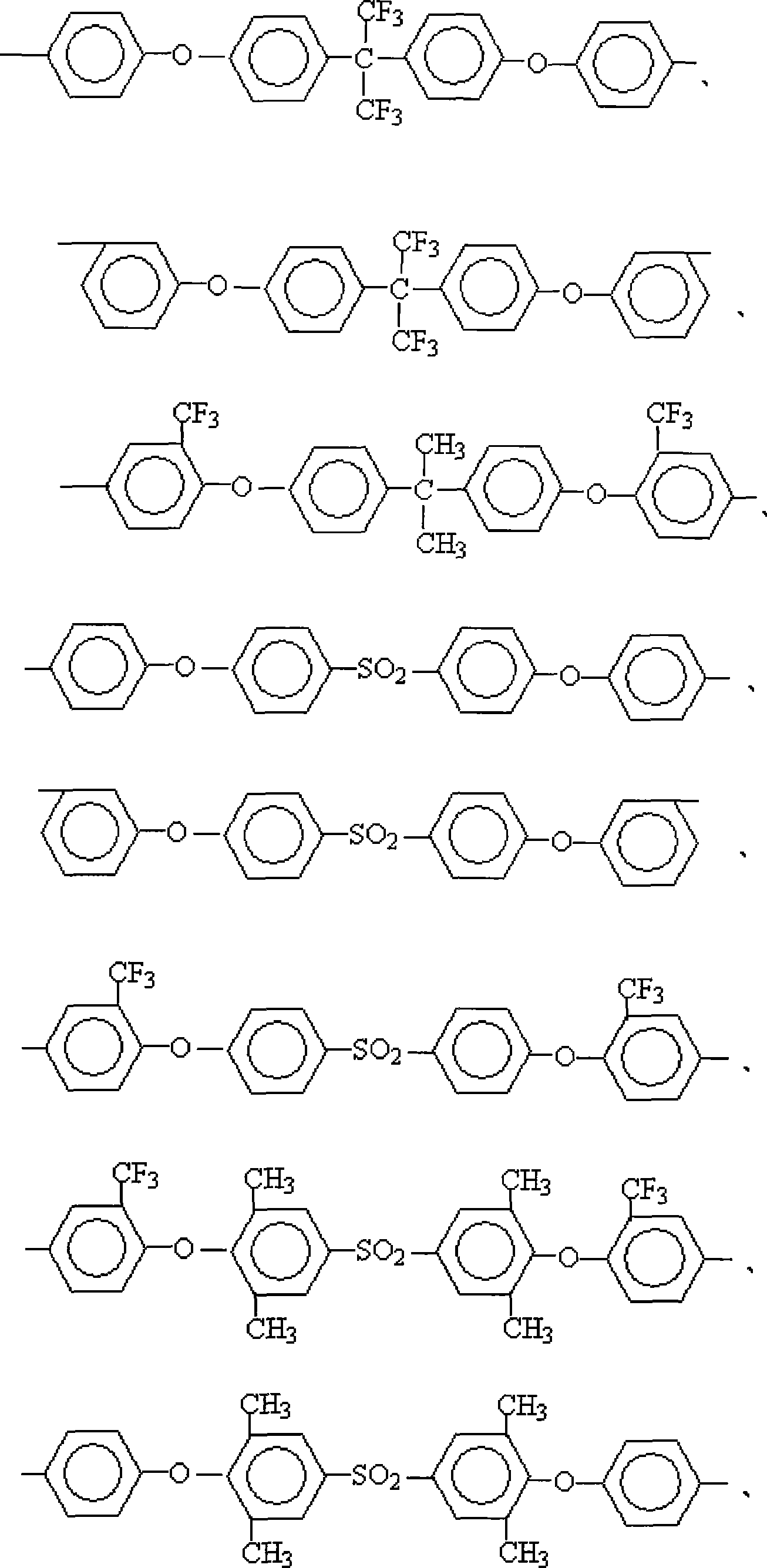

Method used

Image

Examples

Embodiment 1

[0032] 22.6 grams (0.1 moles) of 3,3'-dimethyl-4,4'-diaminodiphenylmethane, 24.8 grams (0.1 moles) of 4,4'-diaminodiphenylsulfone, 400 grams of E-44 ring Add the epoxy resin into the reaction bottle, react at 60°C for 0.5 hours, add 32 grams of carboxy-terminated nitrile rubber (active toughening agent), and react at 80°C to 110°C for 3 hours to obtain a viscous modified ring Oxygen resin system. Add 40 grams of 3,4-epoxycyclohexylmethyl-3',4'-epoxycyclohexyl carbonate reactive diluent, 10 grams of dicyandiamide and 30 grams of methyltetrahydrophthalic anhydride two curing agents, stir well , obtained a high-strength solvent-free epoxy adhesive.

[0033] Take an appropriate amount of the adhesive obtained above, and evenly spread it on the standard iron test piece. Cool to room temperature.

[0034] The adhesive system has good viscosity controllability, can be adjusted in a wide range, has good manufacturability, and has excellent adhesion to metal substrates (including ir...

Embodiment 2

[0036]20 grams (0.1 mol) of 4,4'-diaminodiphenyl ether, 24.8 grams (0.1 mol) of 4,4'-diaminodiphenylsulfone, 50 grams of E-51 epoxy resin, 180 grams of N,N, Add N', N',-tetraglycidyl-4,4'-diaminodiphenylmethane into the reaction flask, react at 60°C for 0.5 hours, at 80°C for 0.5 hours, and at 100°C for 0.5 hours, add 46 g Carboxyl-terminated nitrile rubber (active toughening agent), react at a temperature of 80°C to 110°C for 1 hour to obtain a viscous modified epoxy resin system. Add 2300 grams of 3,4-epoxycyclohexylmethyl-3',4'-epoxycyclohexyl carbonate reactive diluent, 30 grams of dicyandiamide and 200 grams of 3,3',4,4'-tetracarboxylic acid Diphenyl ether dianhydride powder and two curing agents are stirred evenly to obtain a high-strength solvent-free epoxy adhesive.

[0037] Take an appropriate amount of the adhesive obtained above, and evenly spread it on the standard iron test piece. Cool to room temperature.

[0038] The adhesive system has good viscosity control...

Embodiment 3

[0040] Add 24.8 grams (0.1 moles) of 4,4'-diaminodiphenyl sulfone and 160 grams of E-51 epoxy resin into the reaction flask, and react at a temperature of 60°C to 100°C for 2 hours, then add 10 grams of carboxy-terminated butyl Nitrile rubber (active toughening agent) and 10 grams of phenolic hydroxyl-containing polyimide powder (active toughening agent: Shanghai EMST Electronic Materials Co., Ltd.) were reacted at a temperature of 80°C to 110°C for 2 hours to obtain viscous Modified epoxy resin system. Add 800 grams of 3,4-epoxycyclohexylmethyl-3',4'-epoxycyclohexyl carbonate reactive diluent, 30 grams of dicyandiamide curing agent, stir evenly, and obtain a high-strength solvent-free epoxy adhesive mixture.

[0041] Take an appropriate amount of the adhesive obtained above, and evenly spread it on the standard iron test piece. Cool to room temperature.

[0042] The adhesive system has good viscosity controllability, can be adjusted in a wide range, has good manufacturabil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com