Solar battery backboard taking modified polyvinylidene fluoride alloy layer as weathering protective layer

A technology of polyvinylidene fluoride and solar cells, which is applied in the direction of synthetic resin layered products, circuits, electronic equipment, etc., can solve the problems of not being able to be used directly, low surface energy, etc., achieve low cost, increase surface energy, and good weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

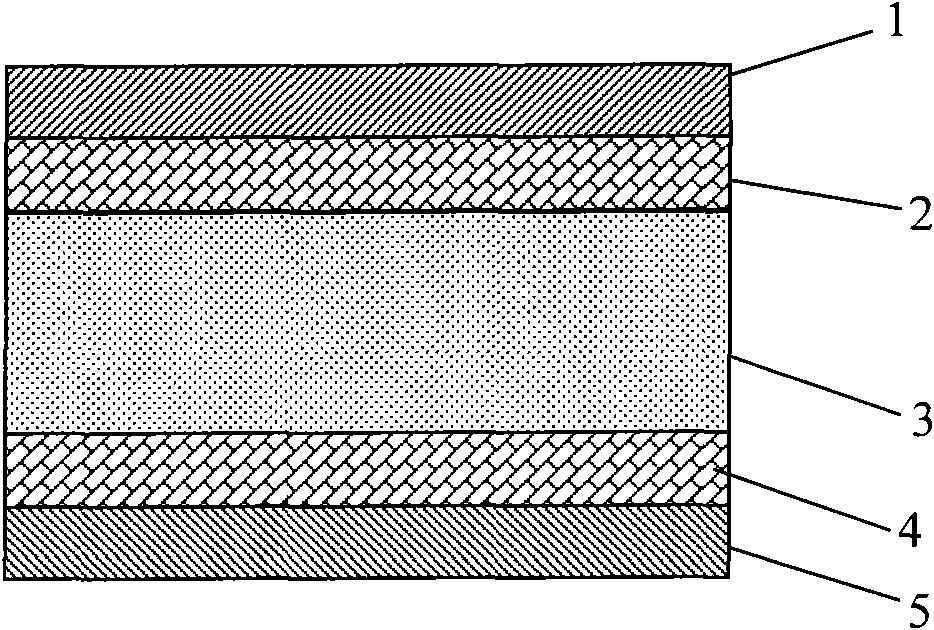

[0023] See figure 1 As shown, the solar battery back sheet using the modified polyvinylidene fluoride alloy layer as the weather-resistant protective layer of the present invention includes a first weather-resistant layer 1, a first adhesive layer 2, a structural reinforcement layer 3, a second adhesive layer 4 and The second weather-resistant layer 5, the first weather-resistant layer 1 is bonded to the structural reinforcement layer 3 through the first adhesive layer 2, and the structural reinforcement layer 3 is bonded to the structural reinforcement layer 4 through the second bonding layer 4. The second weather-resistant layer 5, the first weather-resistant layer 1 and the second weather-resistant layer 5 are polyvinylidene fluoride (PVDF) alloy layers modified with inorganic materials.

[0024] Preferably, the inorganic material is sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com