48 head square spinning path

A spinning tunnel and tunnel technology, which is applied in the field of textile equipment accessories, can solve the problems of increasing capital investment, land occupation area and energy consumption, increasing floor space and energy consumption, etc., so as to ensure the spinning speed and quality stability, and reduce investment. , the effect of rectification uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

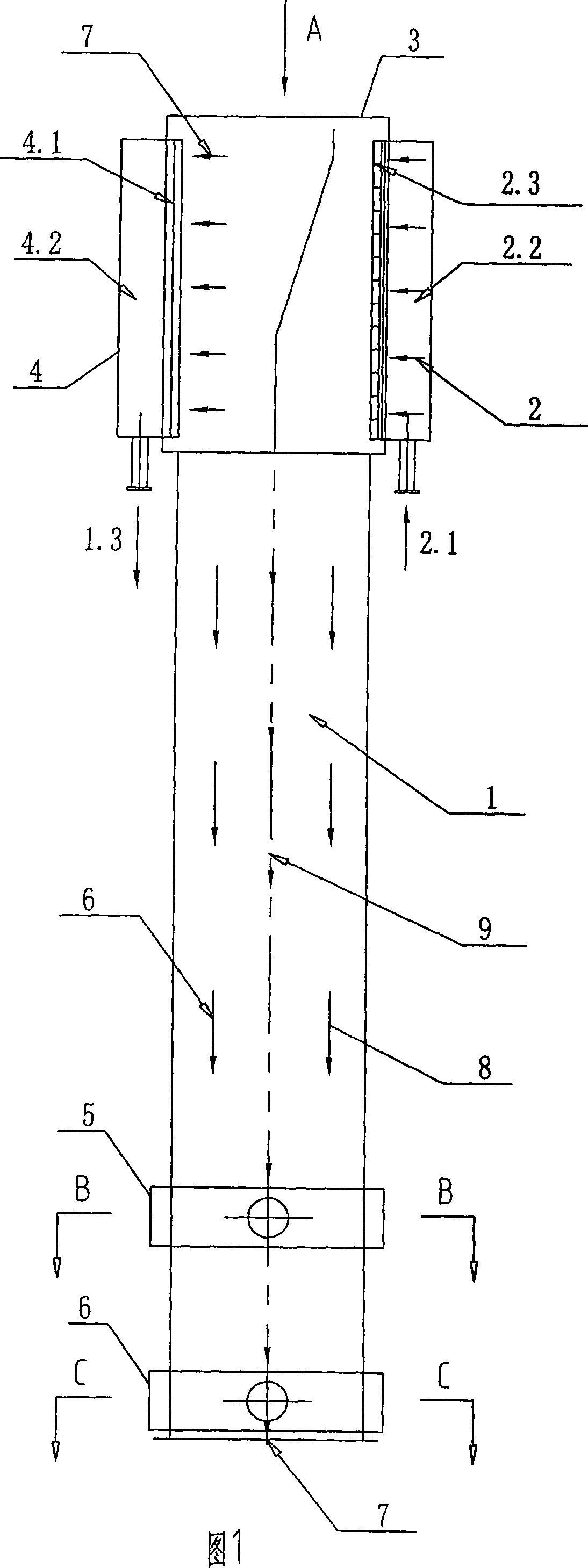

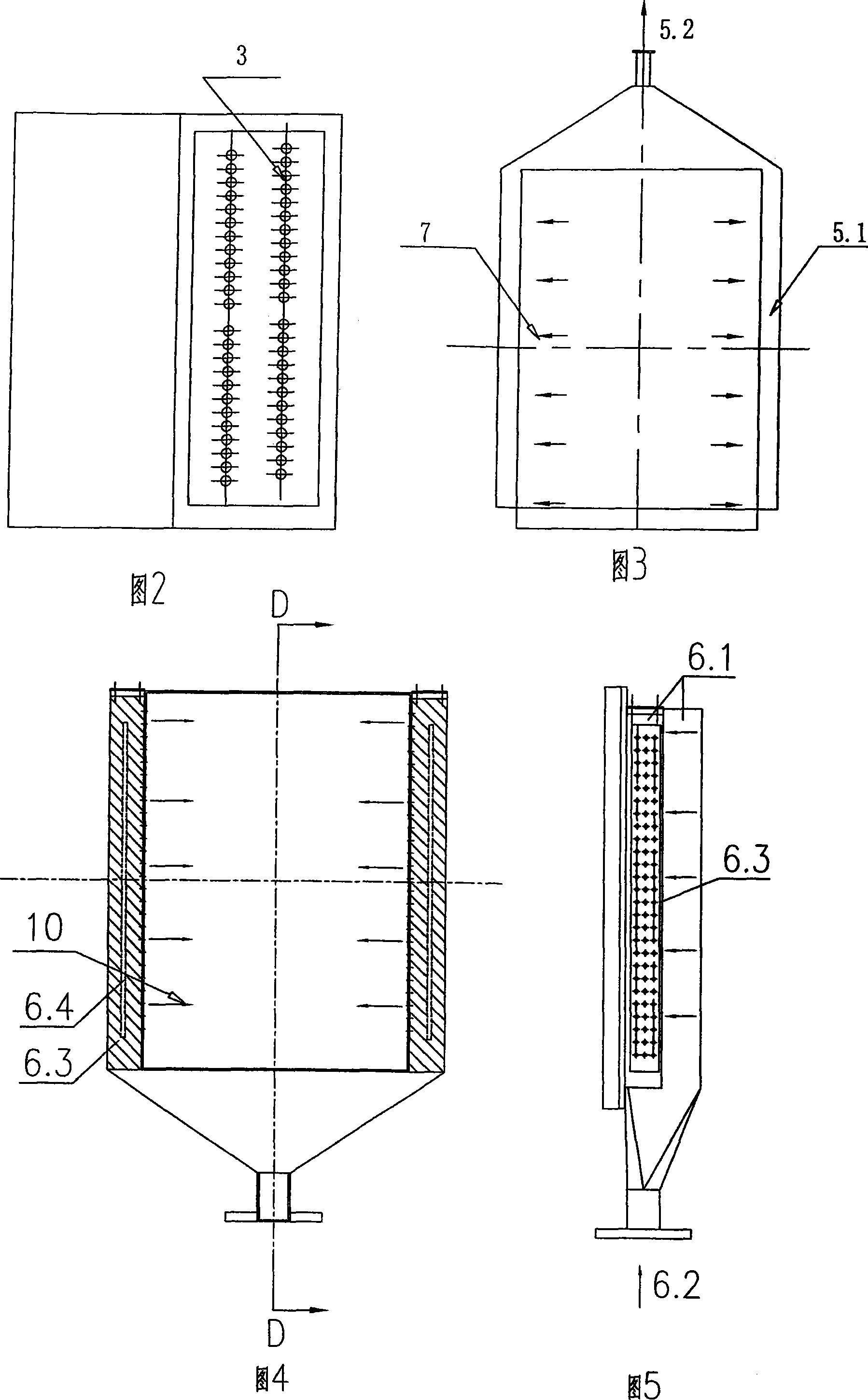

[0013] Referring to Fig. 1-2, the 48 square spinning tunnels of the present invention are mainly composed of a square cylindrical tunnel body 1, an upper air inlet chamber 2, 48 spinning assemblies 3, an upper return air chamber 4, and a lower return air device 5 It is composed of the lower nitrogen air curtain device 6. The 48 spinning assemblies 3 are arranged on the top of the square cylindrical tunnel body 1, the upper air inlet chamber 2 and the upper return air chamber 4 are respectively arranged on the left and right sides of the top of the square cylindrical tunnel body 1, and the lower air return device 5 and the lower nitrogen air curtain device 6 are spaced up and down at the bottom of the square tube-shaped tunnel body 1 .

[0014] The upper air inlet chamber 2 is composed of an air inlet static plenum 2.2, a hot air inlet 2.1 and an air inlet rectifier 2.3. The hot air inlet 2.1 is arranged at the bottom of the air inlet static plenum 2.2, and the air inlet recti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com