Forging method of disc-shaped integrated part and die used for forging method

An integrated and part-based technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve problems such as high equipment tonnage and precision requirements, and great difficulty in forging quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

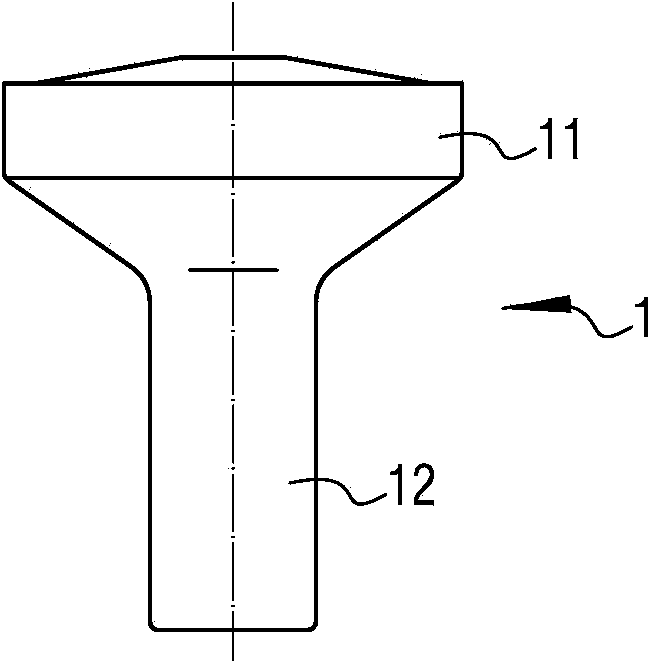

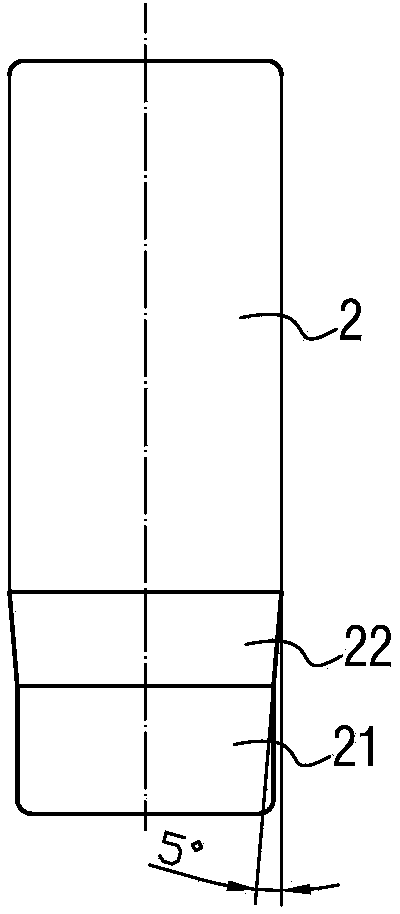

[0023] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

[0024] As mentioned in the background technology section, in view of the lack of special equipment and technology for processing the integrated parts of the disk and shaft in my country, it is difficult to ensure the stable production quality of the parts, the present invention provides a forging method for the integrated parts of the disk and shaft , its essence is to use the existing equipment to form the disc body by die forging, and then use free forging to pull out the long rod. The present invention specifically designs the die forging die, thereby effectively controlling the degree of deformation of the material and avoiding the dead zone of deformation; in addition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com