Process for refining isatis root extract by applying membrane separation technique

A process method and technology of separation technology, which are applied in the field of separation and concentration of extracts of medicinal materials of Radix isatidis preparations, can solve the problems of large amount of ethanol, long production process cycle, unfavorable safety production, etc., so as to ensure quality stability, reduce production costs, shorten The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

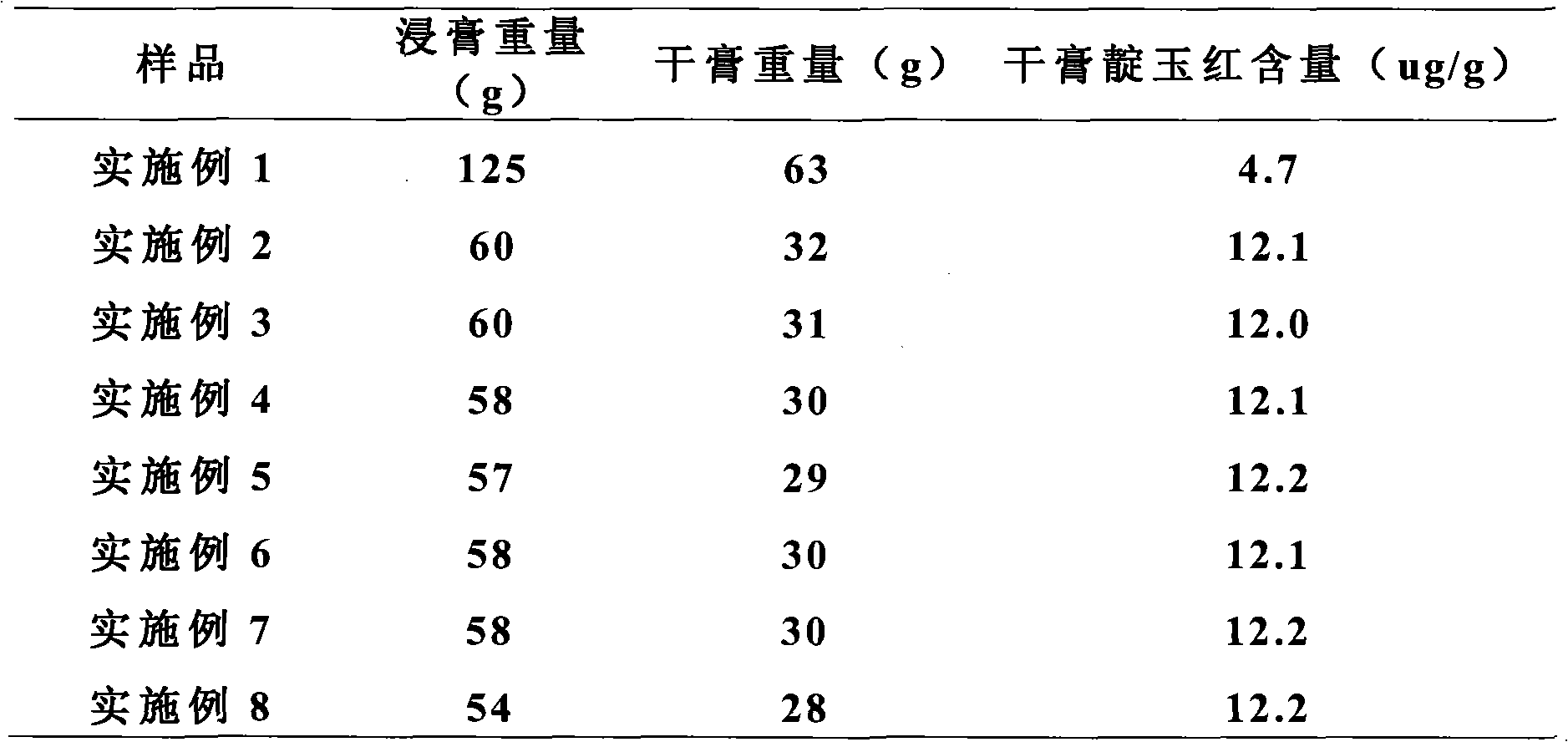

Embodiment 1

[0019] This embodiment shows the existing process method: get Radix Radix 1400g, add 10 times the amount of water to decoct twice, the first time for 2 hours, the second time for 1 hour, combine the decoction, filter, and the filtrate is concentrated to a relative density of 1.20 (50°C), add 4L of ethanol to make the alcohol content 60%, let it stand for precipitation, take the supernatant, recover the ethanol and concentrate to a relative density of 1.3 (50°C), to obtain 125g of Radix Radix Radix Extract.

Embodiment 2

[0021] This embodiment and the following embodiments have all adopted the processing method of the present invention, take Radix Radix 1400g, add 10 times the amount of water to decoct twice, for the first time for 2 hours, for the second time for 1 hour, combine the extracts, extract The liquid is centrifuged with a three-legged centrifugal device, and the centrifuged liquid is filtered with an inorganic ceramic membrane, the membrane pore size is 200nm, the filtration pressure: 0.1-0.4Mpa, the temperature: 15°C-85°C, collect the clear liquid, and concentrate the clear liquid with a nanofiltration membrane to a relatively high temperature. The density is 1.30 (50°C), the operating pressure is 2-4Mpa, and the flow rate is 1-3L / m 2 h, to obtain Radix Radix Radix Extract 60g.

Embodiment 3

[0023] Take 1400g of Radix isatidis, add 10 times the amount of water to decoct twice, the first time is 2 hours, the second time is 1 hour, the extract is combined, the extract is centrifuged with a three-legged centrifugal device, and the centrifuge is filtered with an inorganic ceramic membrane. 100nm, filtration pressure: 0.1~0.4Mpa, temperature: 15℃~85℃, collect the supernatant, concentrate the supernatant to a relative density of 1.30 (50℃) with nanofiltration membrane, operating pressure 2~4Mpa, flow rate 1~ 3L / m 2 h, to obtain Radix Radix Radix Extract 60g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com