BOPP film with endurable and smoothness characteristics and preparation method therefor

A smooth and thin film technology, applied in packaging film materials, BOPP film with durable and smooth characteristics and its preparation field, can solve the problems of decreased gloss, shortened timeliness of use by downstream customers, increased haze, etc., to delay migration The speed to the surface of the film, the stability of product quality, and the effect of increasing the action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

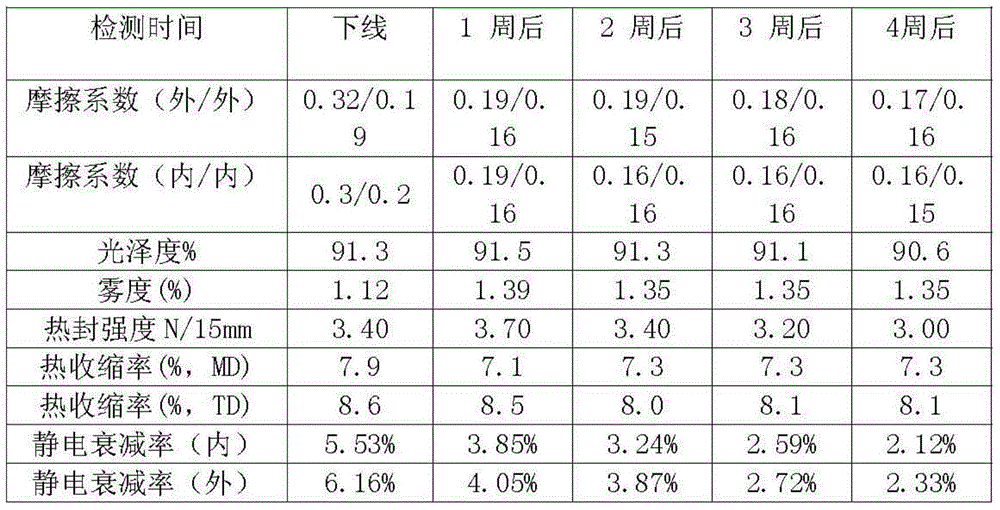

Image

Examples

Embodiment Construction

[0028] The BOPP film with durable and slippery properties of the present invention is mainly formed by a core layer, a surface layer on both sides of the core layer and an inner layer co-extruded and formed, and the surface layer is made of the following raw materials in weight percentage: homopolypropylene resin 96.0 %-96.8%, slip agent 0.1%-2.0%, anti-blocking agent 0.1%-2.0%; the core layer is made of the following weight percentage of raw materials: homopolypropylene resin 99.5%-99.7%, antistatic agent 0.3%-0.5%; The inner layer is made of the following weight percentages of raw materials: homopolypropylene resin 84.1%-84.9%, slip masterbatch 14.0%-14.9%, anti-blocking agent 0.1%-2.0%, so The isotacticity of the homopolypropylene resin is above 95%.

[0029] The slipping masterbatch used in the inner layer is made by blending homopolypropylene resin, nano-inorganic materials and slip agents. The nano-inorganic materials are selected from among nano-silica, nano-calcium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com