Preparation method of natural spice superfine powder and application of natural spice superfine powder in tobacco sheets

A technology of natural spices and tobacco flakes, which is applied in the field of cigarette flavors and fragrances, can solve the problems of tobacco flakes with obvious miscellaneous gas, insufficient aroma, and strong stimulation, and achieve the effect of enriching the aroma, coordinating with the aroma of cigarettes, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

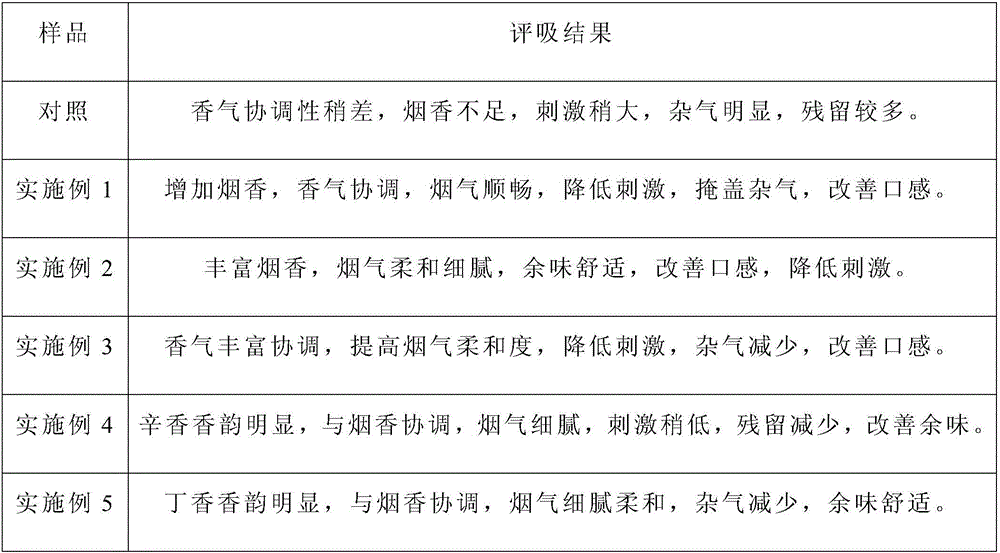

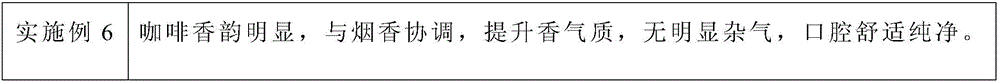

Examples

Embodiment 1

[0015] Embodiment 1, a kind of preparation method of natural flavor superfine powder, its specific preparation steps are as follows:

[0016] (1) Put commercially available hawthorn in a blast drying oven at 50° C. for 5 hours and dry it for 5 hours. After crushing, pass through a 60-mesh sieve to make hawthorn fine powder.

[0017] (2) Put the hawthorn fine powder into an air-flow ultrafine pulverizer, pulverize twice under the conditions of a feed rate of 1 kg / h and a working pressure of 0.8 MPa, and collect hawthorn ultrafine powder with a particle size of 8-12 μm.

[0018] Add the hawthorn superfine powder product prepared in Example 1 into the pulp-making tank, and the addition amount is 0.3% of the total weight of the pulp in the pulp tank. After stirring evenly, the pulp will form a fiber flake base through papermaking and drying processes, and then concentrate The liquid is directly dip-coated or spray-coated on the sheet base, and finally dried and cut to obtain the t...

Embodiment 2

[0019] Embodiment 2, a kind of preparation method of natural fragrance superfine powder, its specific preparation steps are as follows:

[0020] (1) Put commercially available red dates into a blast drying oven at 55° C. to dry for 4 hours, crush them and pass through a 40-mesh sieve to make red date fine powder.

[0021] (2) Put the jujube fine powder into an air-flow ultrafine pulverizer, pulverize twice under the condition of feeding speed 1.5kg / h and working pressure 0.5MPa, and collect the jujube superfine powder with a particle size of 8-12 μm.

[0022] The jujube superfine powder product prepared in Example 2 is added in the pulp-making tank, and the addition amount is 0.5% of the total weight of the pulp in the pulp tank. After stirring evenly, the pulp is formed into a fiber flake base through papermaking and drying processes, and then concentrated The liquid is directly dip-coated or spray-coated on the sheet base, and finally dried and cut to obtain the tobacco shee...

Embodiment 3

[0023] Embodiment 3, a kind of preparation method of natural fragrance superfine powder, its specific preparation steps are as follows:

[0024] (1) Put commercially available licorice into a blast drying oven at 50°C and dry for 5 hours, crush it and pass it through a 60-mesh sieve to make licorice fine powder.

[0025] (2) Put the fine powder of licorice into an air-flow ultrafine pulverizer, pulverize once under the conditions of feed rate 1.0kg / h and working pressure 1.0MPa, and collect ultrafine powder of licorice with a particle size of 8-12 μm.

[0026] The licorice superfine powder product prepared in Example 3 is added in the pulp-making tank, and the addition amount is 0.2% of the total weight of the pulp in the pulp tank. After stirring evenly, the pulp forms a fiber flake base through papermaking and drying processes, and then the concentrated The liquid is directly dip-coated or spray-coated on the sheet base, and finally dried and cut to obtain the tobacco sheet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com