Low-temperature delayed-curing sand-control proppant, preparation method of proppant as well as low-temperature delayed-curing sand-control system

A proppant and curing agent technology, applied in chemical instruments and methods, mining fluids, earthwork drilling, etc., can solve problems such as poor temperature resistance and inability to cure, and achieve stable quality, convenient operation, and improved compression resistance. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

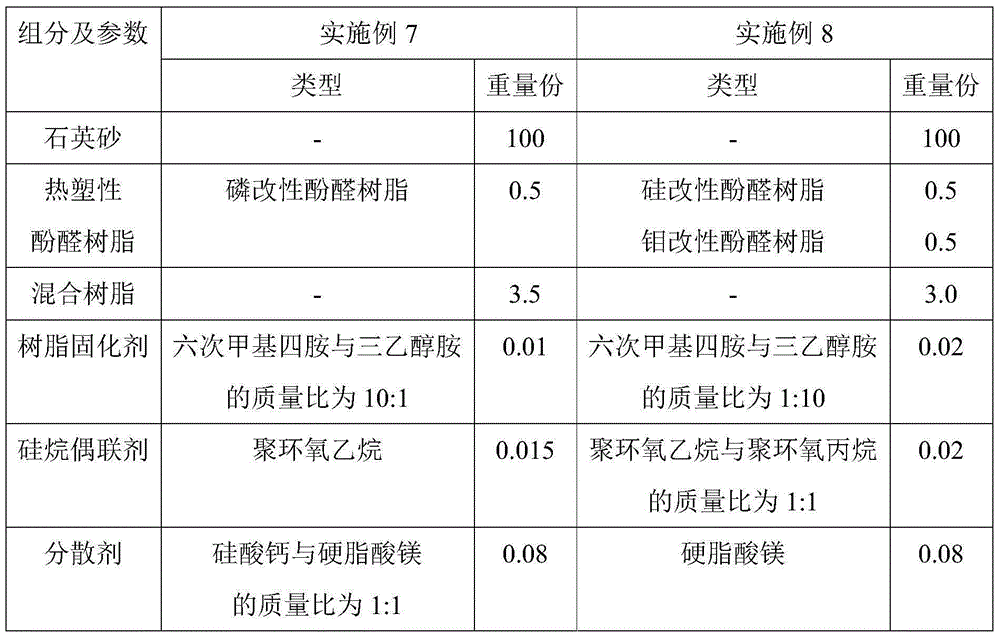

Embodiment 1

[0039] The low-temperature delayed-curing sand control proppant of this embodiment is proppant particles, the proppant particles include quartz sand and a composite resin layer coated on the surface of the quartz sand, and the composite resin layer includes a resin inner layer and a resin outer layer The resin inner layer is a thermoplastic phenolic resin layer formed by thermoplastic phenolic resin; the resin outer layer is a mixed resin layer, and the mixed resin layer is composed of the following components in parts by weight: 2.0 parts of mixed resin, resin curing 0.01 part of agent, 0.01 part of silane coupling agent, and 0.05 part of dispersant; wherein, the mixed resin is a mixture of thermoplastic phenolic resin and epoxy resin in a mass ratio of 70:30; the quartz sand, resin inner layer and resin The mass ratio of the mixed resin in the outer layer is 100:2.0:2.0. The particle size of the proppant particles is 40-70 mesh (212-425 μm).

[0040] Wherein, the thermoplas...

Embodiment 2

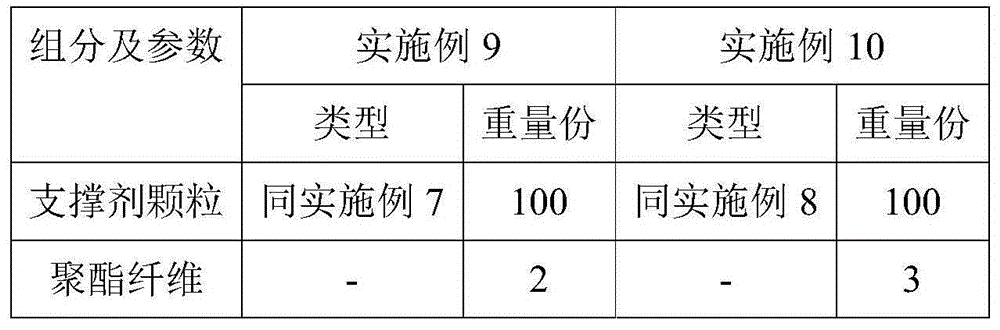

[0043] The low-temperature delayed curing sand control proppant of this embodiment is composed of proppant particles and polyester fibers, the mass ratio of the polyester fibers to the proppant particles is 1:100; the polyester fibers are polyester coarse fibers, The average diameter is 1.2mm, and the average length is 8mm.

[0044] The proppant particles are the proppant particles described in Example 1.

[0045] The preparation method of the low-temperature time-delayed solidification sand control proppant in this example is as follows: 10 kg of quartz sand with a particle size of 212-425 μm is placed in a sand mixer, heated to 100° C., and 200 g of thermoplastic phenolic resin is added under stirring conditions. Continue to stir for 60s for the first coating; then continue to stir and add 200g of mixed resin, 1g of resin curing agent, 1g of silane coupling agent, continue to stir for 80s, then add 5g of dispersant, continue to stir for 30s for the second coating, discharge ...

Embodiment 3

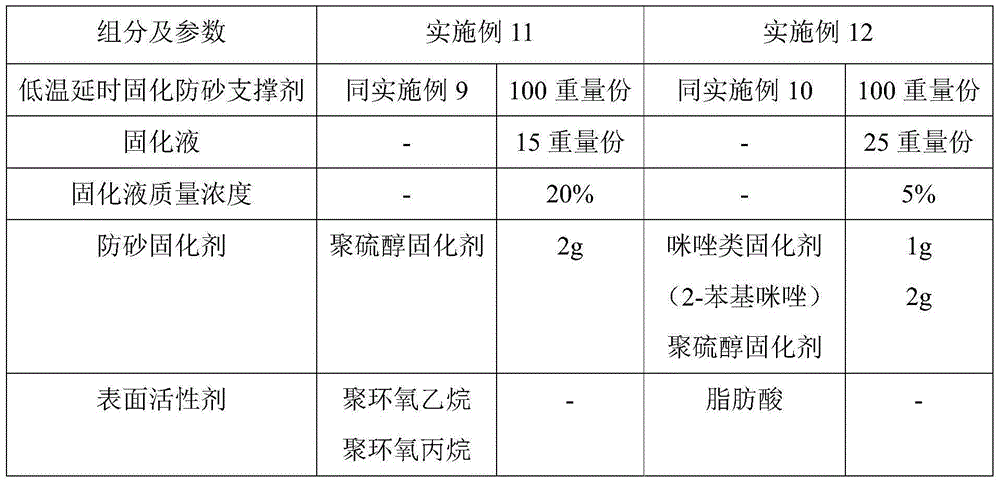

[0047] The low-temperature time-delay solidification sand control system of this embodiment is composed of a solidification liquid and the low-temperature time-delay solidification sand control proppant of Example 2, and the volume ratio of the solidification liquid to the low temperature time delay solidification sand control proppant is 5:100; The curing liquid is a sand control curing agent solution with a mass concentration of 10%; in the sand control curing agent solution, the sand control curing agent is an imidazole curing agent (2-methylimidazole); the sand control curing agent solution also contains a surfactant , the surfactant is glycerol triacetate, and the addition of surfactant is: the surfactant of every 3g sand control curing agent is correspondingly added 1ml; The used solvent of described sand control curing agent solution is the mixture of water and ethanol , The amount of ethanol is: 10ml of ethanol is added for every 3g of sand control curing agent.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com