Manufacturing machine and method of titanium alloy parts

A technology of titanium alloy and preparation machine, which is applied in the direction of metal material coating process, coating, etc., can solve the problem that it is difficult to obtain high-temperature titanium alloy or titanium-aluminum alloy filaments, the performance of titanium alloy or titanium-aluminum alloy structural parts is insufficient, Can not obtain different problems according to different needs, and achieve the effect of short preparation cycle, tight interlayer bonding and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

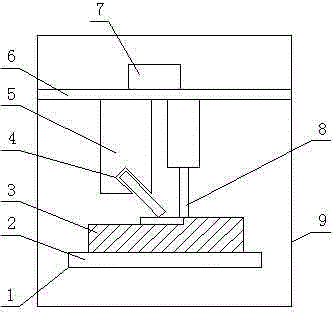

[0030] Such as figure 1 As shown, a preparation machine for titanium alloy parts includes a body 1, the lower part of the body 1 is a mobile platform 2, the upper part of the mobile platform 2 is provided with a preform 3, and the upper part of the preform 3 is provided with a thermomechanical processing head 8 , one side of the thermomechanical processing head 8 is provided with a titanium alloy rod material hopper 5, the upper part of the titanium alloy rod material hopper 5 and the thermomechanical processing head 8 is connected with a moving guide rail 6, and the upper part of the moving guide rail 6 is provided with a driving titanium alloy rod material The bucket 5 and the driver 7 of the thermal processing mechanical head 8.

[0031] A method for preparing titanium alloy parts, the first step is to put titanium alloy rods into the titanium alloy rod material bucket 5, and the titanium alloy rod material bucket 5 will send out the titanium alloy rods without interruption...

Embodiment 2

[0033] Such as figure 1 As shown, a preparation machine for titanium alloy parts includes a body 1, the lower part of the body 1 is a mobile platform 2 that moves up and down, the upper part of the mobile platform 2 is provided with a preform 3, and the upper part of the preform 3 is provided with a thermomechanical Processing head 8, one side of thermomechanical processing head 8 is provided with titanium alloy rod material hopper 5, and titanium alloy rod material hopper 5 is provided with clamping bar 4, and this clamping bar 4 is inclined shape, and described titanium alloy The rod material bucket 5 is provided with 2-12 clamping rods 4, and the end of the rod close to the direction of the preform 3 is put into contact with the inclined rod clamping place 4, and the titanium alloy rod material bucket 5 and the hot The upper part of the machining head 8 is connected with a moving guide rail 6 that moves horizontally, and the upper part of the moving guide rail 6 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com