Method for controlling structure refinement of cast TiAl-based alloy and form of boride

A technology of borides and base alloys, which is applied in the field of intermetallic compound alloy preparation, can solve the problems that the shape, size and distribution of borides cannot be improved, and achieve the effect of fine grain size, uniform size distribution and uniform structure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

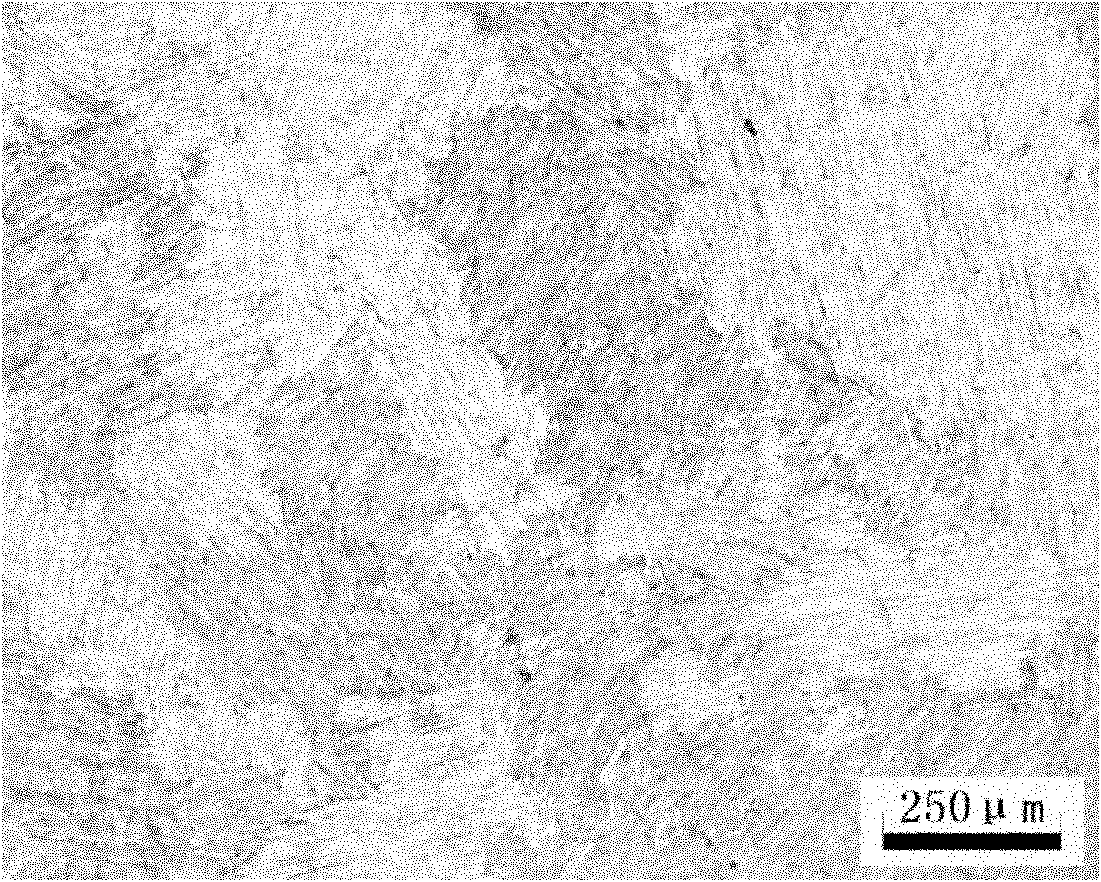

[0035] The nominal composition of the alloy used in the experiment is Al: 47, Cr: 2, Nb: 2, B: 0.8, the balance is Ti (atomic percentage at.%), and the zero-grade sponge titanium with a purity of 99.76% and a purity of 99.99% are selected. High-purity aluminum ingots, pure chromium particles with a purity of 99.90%, niobium flakes with a purity of 99.9% and Ti-3B master alloy are used as raw materials. Put the raw materials into the non-consumable vacuum electric arc furnace and evacuate to 6×10 -3 Pa, filled with high-purity argon to 0.5×10 5 Pa, repeated smelting 4 times, the smelting current is 400-1200A, and a master alloy ingot with a weight of 1.2Kg is prepared. The alloy sample of Φ14mm×80mm is cut by wire cutting method, and filled with Al 2 o 3 -Y 2 o 3 The double-layer structure ceramic tube is placed in a vacuum heat treatment furnace for 30 minutes, and the holding temperature is 20°C below the liquidus temperature, and then quickly quenched into the gallium-i...

Embodiment 2

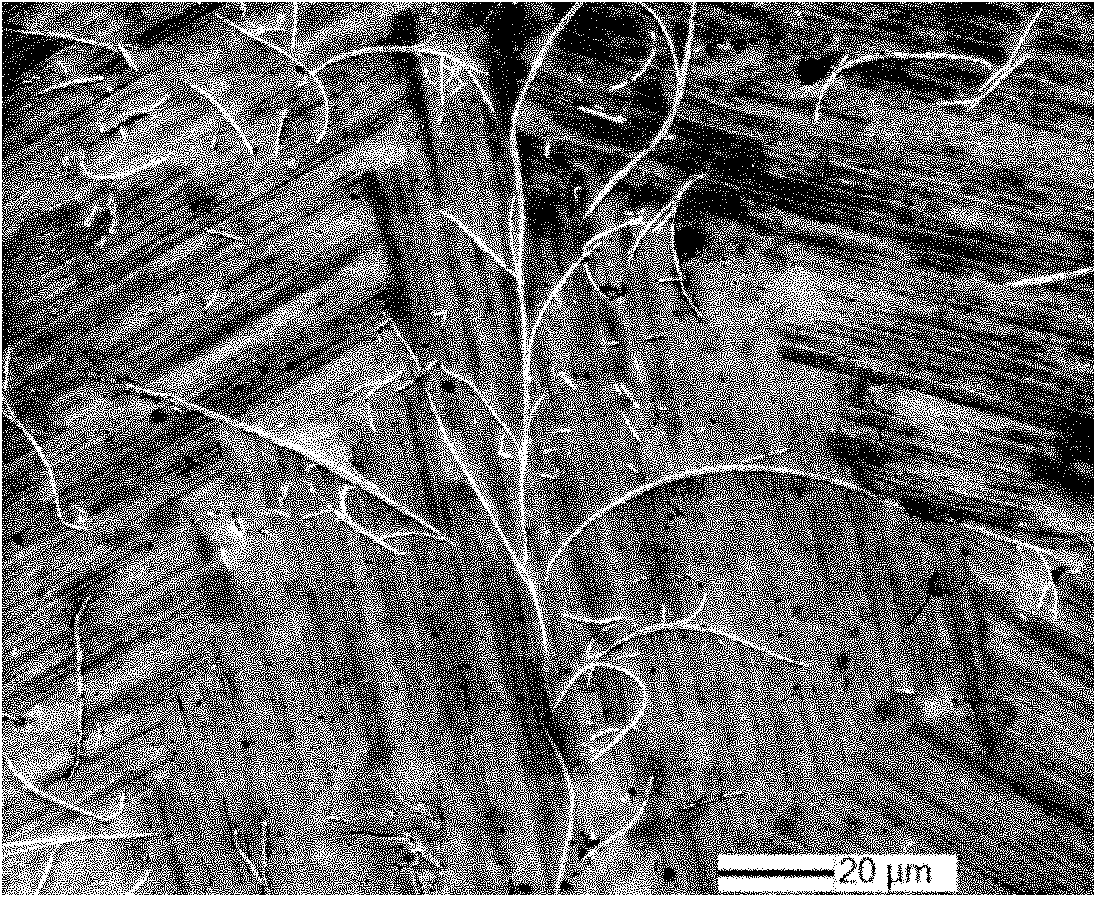

[0042] The nominal composition of the alloy used in the experiment is Al: 47, Cr: 2, Nb: 2, B: 0.8, the balance is Ti (atomic percentage at.%), and the zero-grade sponge titanium with a purity of 99.76% and a purity of 99.99% are selected. High-purity aluminum ingots, pure chromium particles with a purity of 99.90%, niobium flakes with a purity of 99.9% and Ti-3B master alloy are used as raw materials. Put the raw materials into the non-consumable vacuum electric arc furnace and evacuate to 6×10 -3 Pa, filled with high-purity argon to 0.5×10 5 Pa, repeated smelting 4 times, the smelting current is 400-1200A, and a master alloy ingot with a weight of 1.2Kg is prepared. The alloy sample of Φ14mm×80mm is cut by wire cutting method, and filled with Al 2 o 3 -Y 2 o 3 The double-layer structure ceramic tube is placed in a vacuum heat treatment furnace for 30 minutes, and the holding temperature is 20°C below the liquidus temperature, and then quickly quenched into the gallium-ind...

Embodiment 3

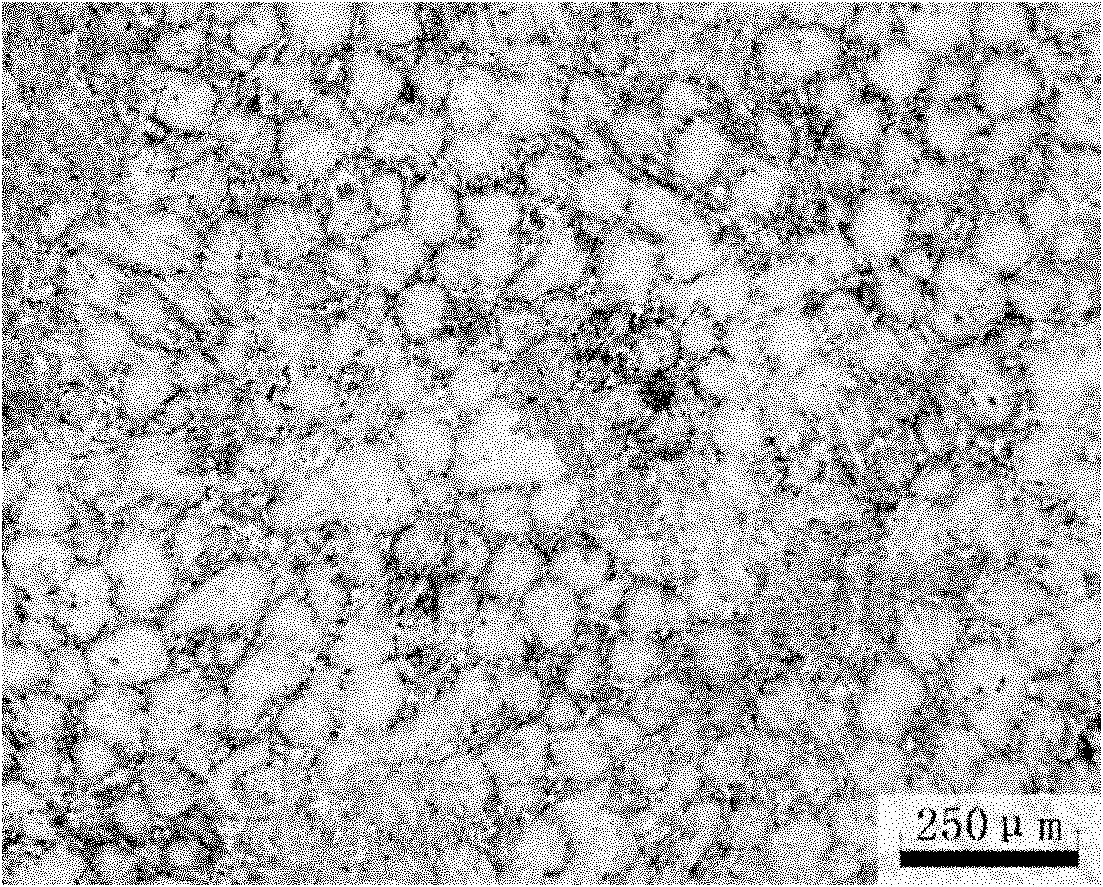

[0046] The nominal composition of the alloy used in the experiment is Al: 47, Cr: 2, Nb: 2, B: 0.8, the balance is Ti (atomic percentage at.%), and the zero-grade sponge titanium with a purity of 99.76% and a purity of 99.99% are selected. High-purity aluminum ingots, pure chromium particles with a purity of 99.90%, niobium flakes with a purity of 99.9% and Ti-3B master alloy are used as raw materials. Put the raw materials into the non-consumable vacuum electric arc furnace and evacuate to 6×10 -3 Pa, filled with high-purity argon to 0.5×10 5 Pa, repeated smelting 4 times, the smelting current is 400-1200A, and a master alloy ingot with a weight of 1.2Kg is prepared. The alloy sample of Φ14mm×80mm is cut by wire cutting method, and filled with Al 2 o 3 -Y 2 o 3 The double-layer structure ceramic tube is placed in a vacuum heat treatment furnace for 30 minutes, and the holding temperature is 20°C below the liquidus temperature, and then quickly quenched into the gallium-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com