Nanostructured superalloy structural components and methods of making

a superalloy and nanostructure technology, applied in the field of superalloys, can solve the problems of affecting the quality of nanostructured alloys,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

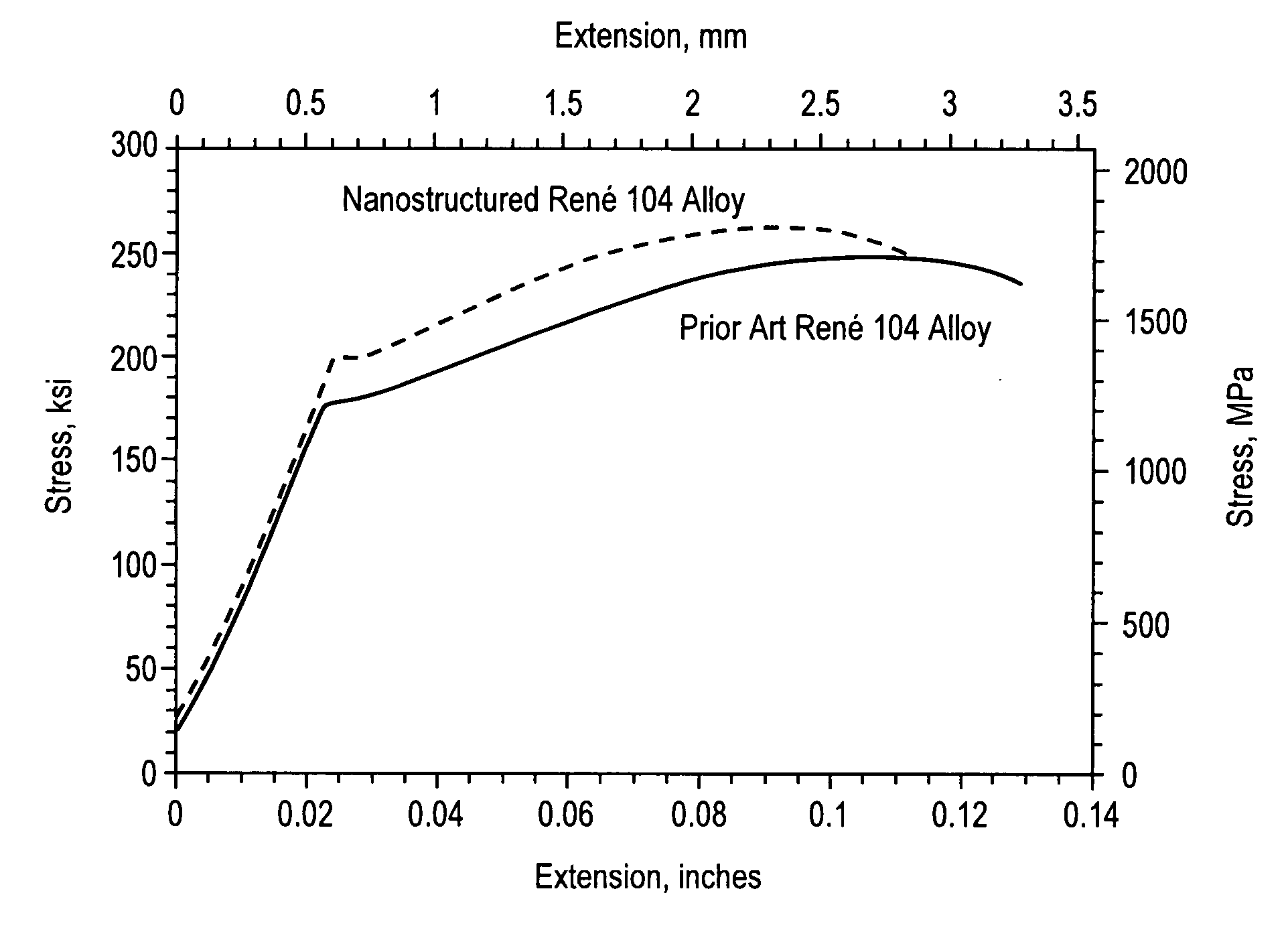

[0036] An alloy, comprising nickel and about 20 wt % Cr (Ni—20Cr), was produced by melting and forging. The average grain diameter after heat treatment of this prior-art material is approximately 64 micrometers (μm). The same base alloy composition was produced as a powder, cryomilled in liquid nitrogen, consolidated, and heat-treated. The grain size after heat treatment of this novel material was about 64 nm. Room temperature tensile tests were conducted on both materials. FIG. 1 illustrates the tensile curves for the two materials. The ultimate tensile strength of the prior art micrometer-scale material was about 87 kilopounds per square inch (ksi), or 600 MegaPascals (MPa), while the ultimate tensile strength of the nanostructured alloy was about 162 ksi (1117 MPa). This represented an 86% higher tensile strength in the alloy produced by the methods disclosed herein.

example 2

[0037] A nanostructured Ni—20Cr sample was prepared as described in Example 1, except that, in addition, a plurality of Al2O3 dispersoid nanoparticles were introduced prior to cryomilling. FIG. 3 presents representative scanning electron microscope images of this superalloy composition.

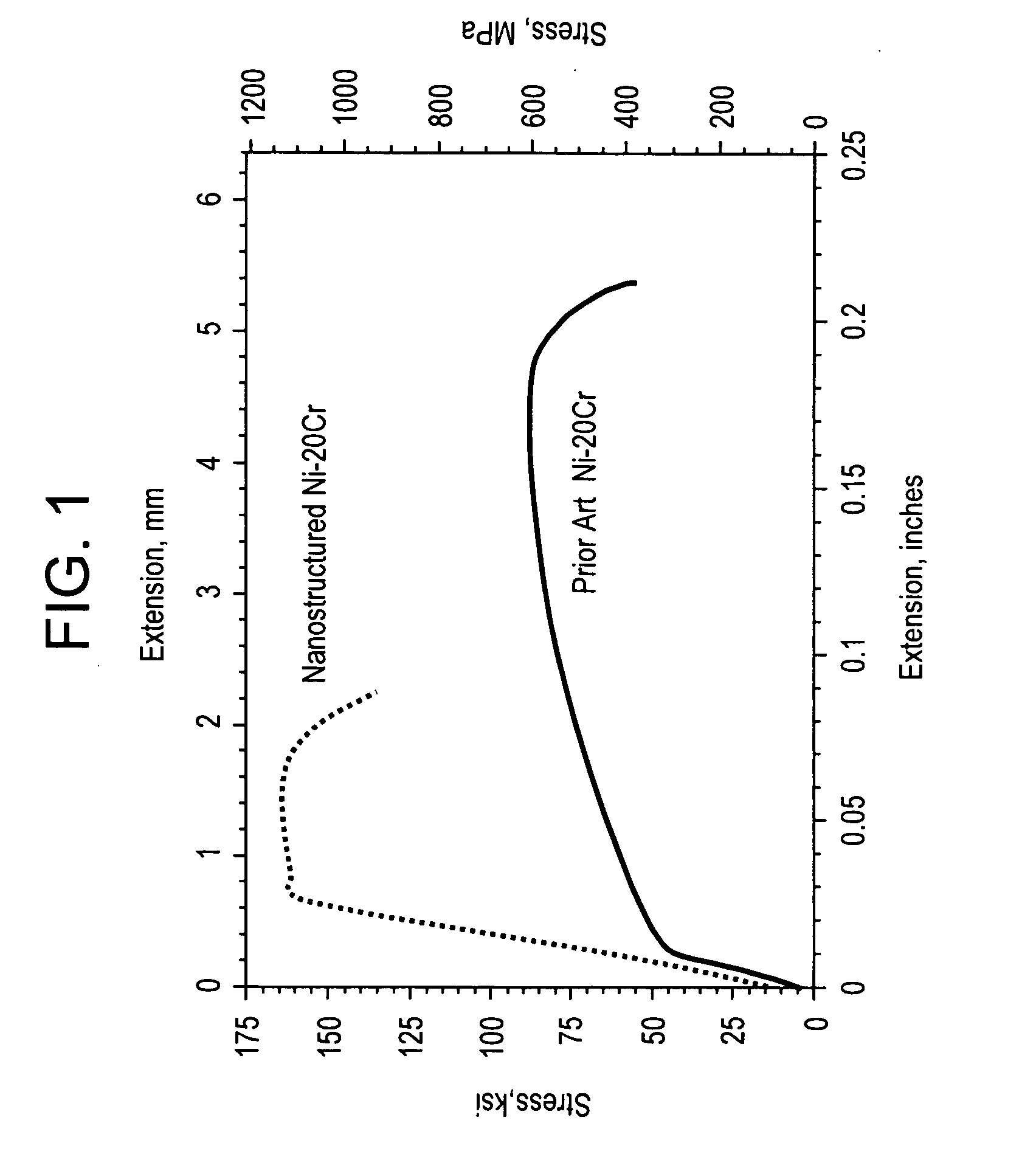

[0038] The fatigue properties of 1) this nanostructured Ni—20Cr superalloy, which had dispersoid nanoparticles introduced at the grain boundaries both ex-situ and in-situ (designated “nanostructured Ni—20Cr w / Al2O3”), 2) a nanostructured Ni—20Cr superalloy prepared according to Example 1, which only had dispersoid nanoparticles introduced at the grain boundaries in-situ (designated “nanostructured Ni—20Cr”), and 3) a known Ni-20Cr superalloy, obtained from Special Metals Corporation under the trade designation INCONEL MA754 (designated “MA754”) were studied. FIG. 2 displays the results of the high-cycle fatigue properties of these three samples. Data is presented for five samples of the nanostructure...

example 3

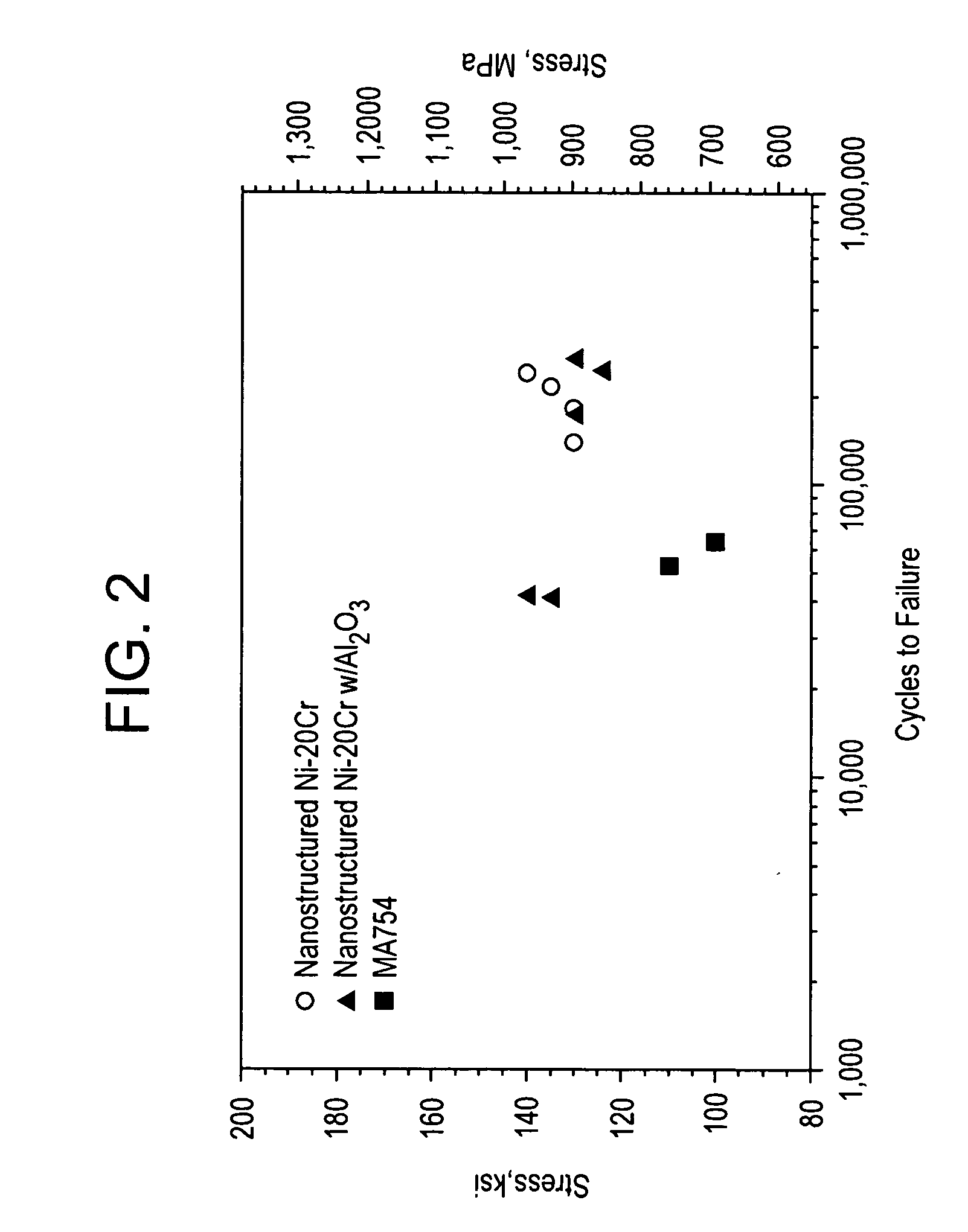

[0039] A René 104 alloy is a nickel-base superalloy having a nominal composition (in weight percent): 0.05 carbon, 3.4 aluminum, 0.05 zirconium, 3.7 titanium, 0.025 boron, 2.4 tantalum, 3.8 molybdenum, 0.9 niobium, 2.4 tantalum, 13 chromium, 20.6 cobalt, balance essentially nickel. The alloy was produced by consolidation of atomized powder, forging, and heat treatment. One sample of the powder was consolidated by hot isostatic pressing, extruded, and heat-treated to yield a micrometer-scale product. Another sample of the powder was cryomilled in liquid nitrogen and subsequently thermo-mechanically processed by hot isostatic pressing, extrusion, and heat treatment in a manner identical to the prior-art micrometer-scale product.

[0040] The two samples were examined by electron microscopy; and tensile tests were conducted. In the nanostructured René 104 alloy of the present disclosure, there is a distribution of small particles of zirconium and aluminum-rich oxides that also had been p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com