Powder extrusion of shaped sections

a technology of shaped sections and extrusion, which is applied in the direction of transportation and packaging, metal-working apparatus, etc., can solve the problems of difficult or costly fabrication of sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

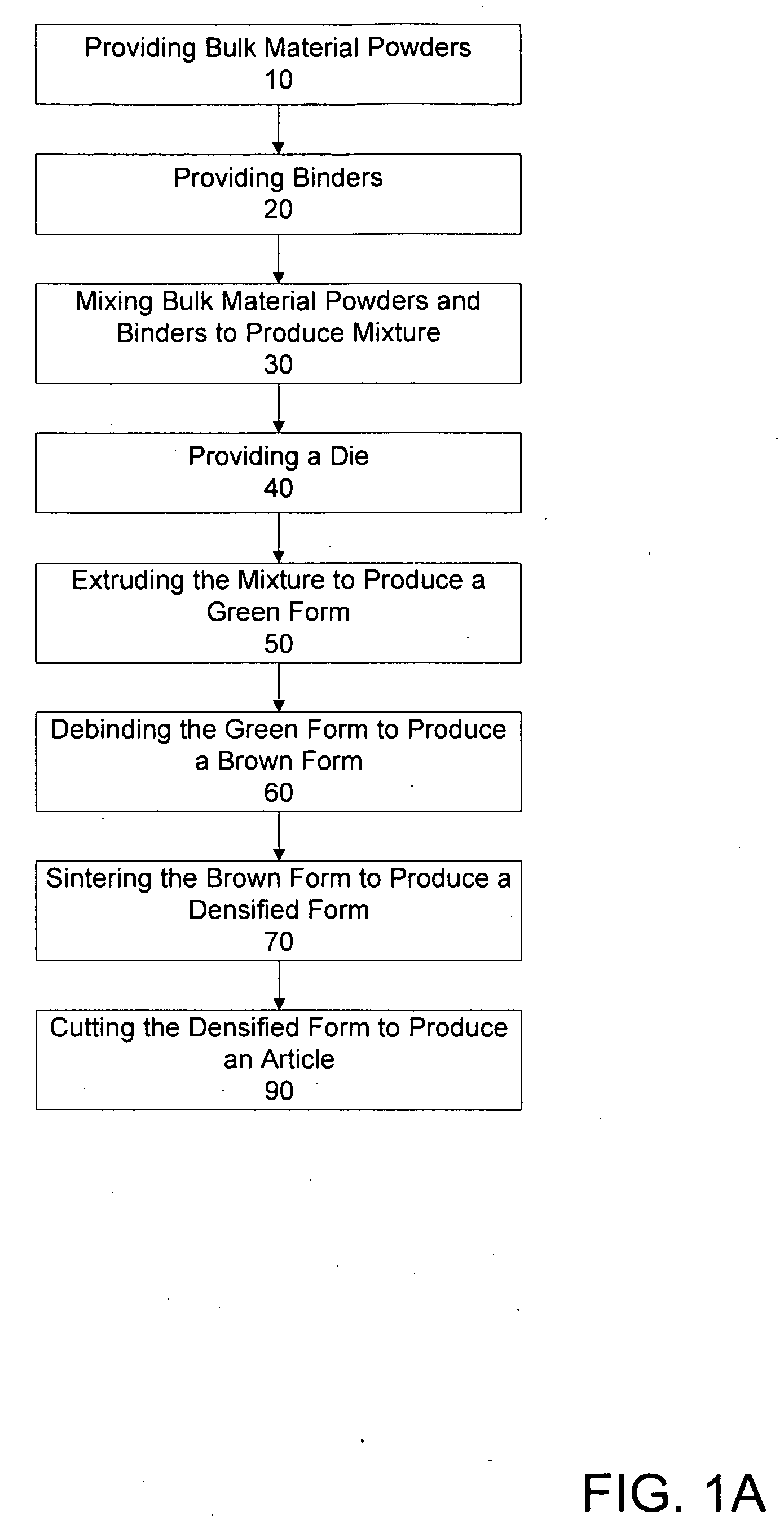

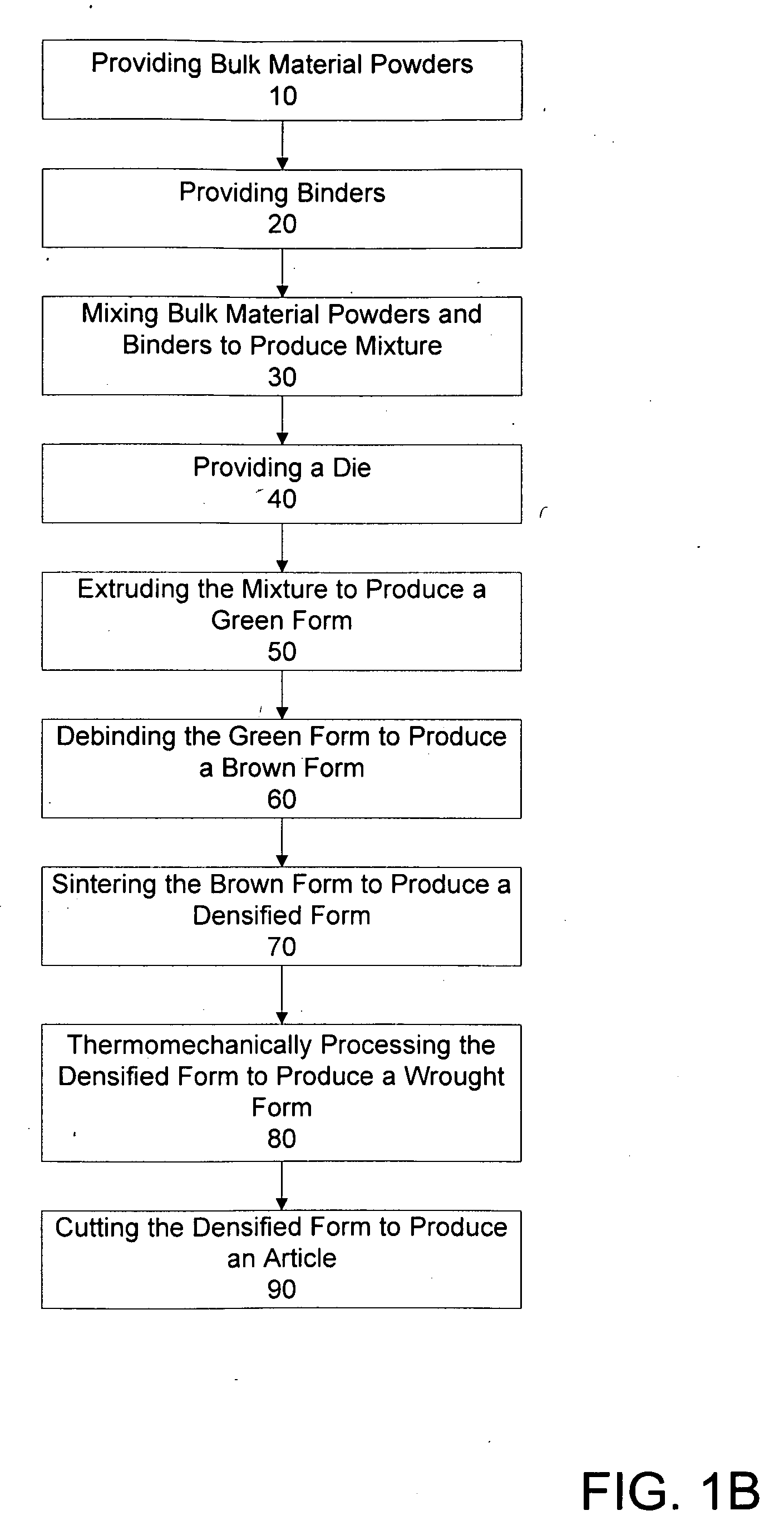

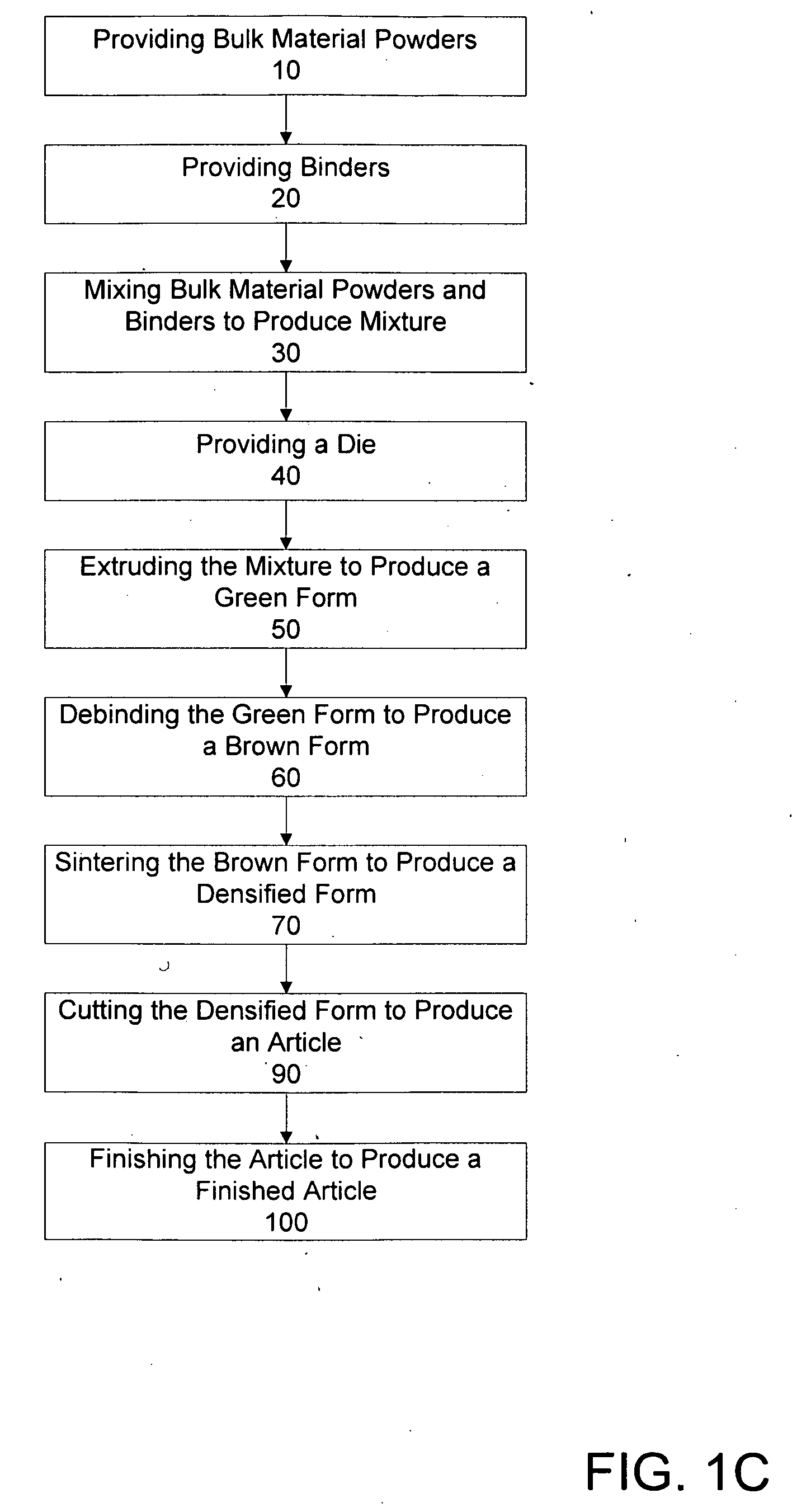

[0026]The present invention provides a method of a making a powder extruded non-molded article having a custom shaped cross-section using a continuous extrusion method. The method uses a mixture of metallic and / or ceramic powders in a polymer and / or inorganic binder that are shaped by being forced under pressure through a die, causing the mixture to be extruded into an elongate form. The resultant elongate form comprises a desired cross-sectional shape and can extend indefinitely from the outlet of the die as a continuous elongate form. The elongate form can be subsequently subjected to mechanical then thermal, and / or thermomechanical processing to achieve a wrought densified form having density and mechanical properties equal to cast and wrought metal. Cutting the form to a net length produces a completed net size article. Net length and net size are the finished length and finished size, respectively, of an article. Further finishing by thermal and various other processes can be a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com