Universal gondola car

An open car and car body technology, applied in the field of railway freight cars, can solve the problems that the carrying capacity of the vehicles cannot be fully utilized, the application conditions of railway freight cars are not the same, and the overall structure of the vehicles is not ideal, so as to achieve safe and fast loading and unloading, and good economic benefits , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be construed that the scope of the above-mentioned subject matter of the present invention is limited to the following examples.

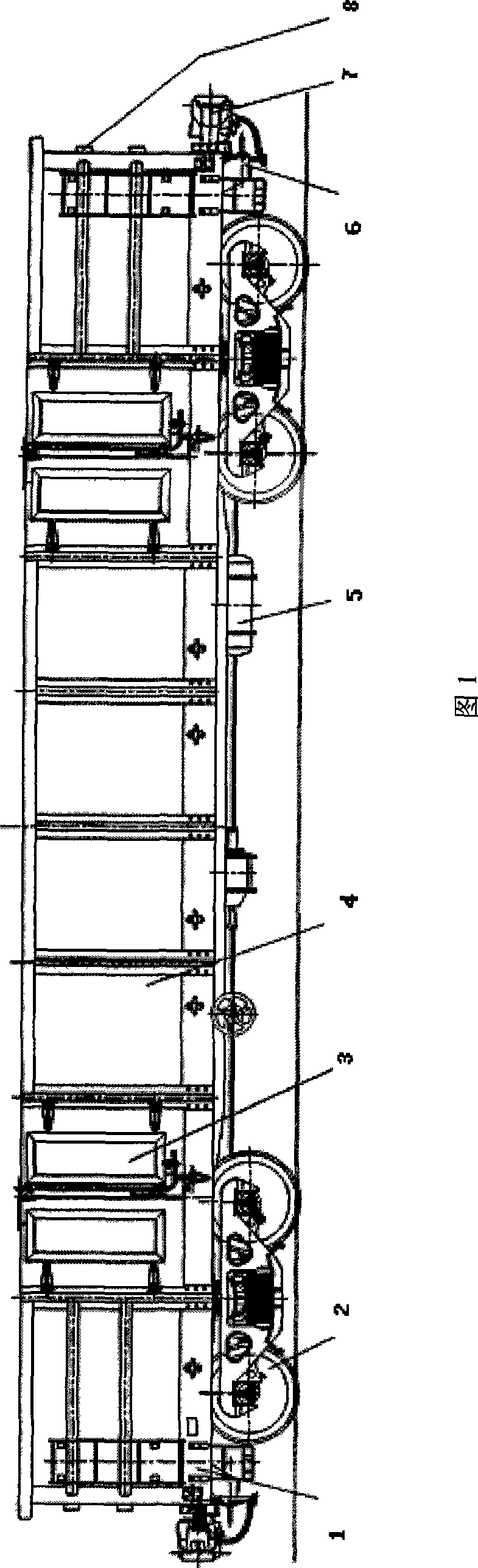

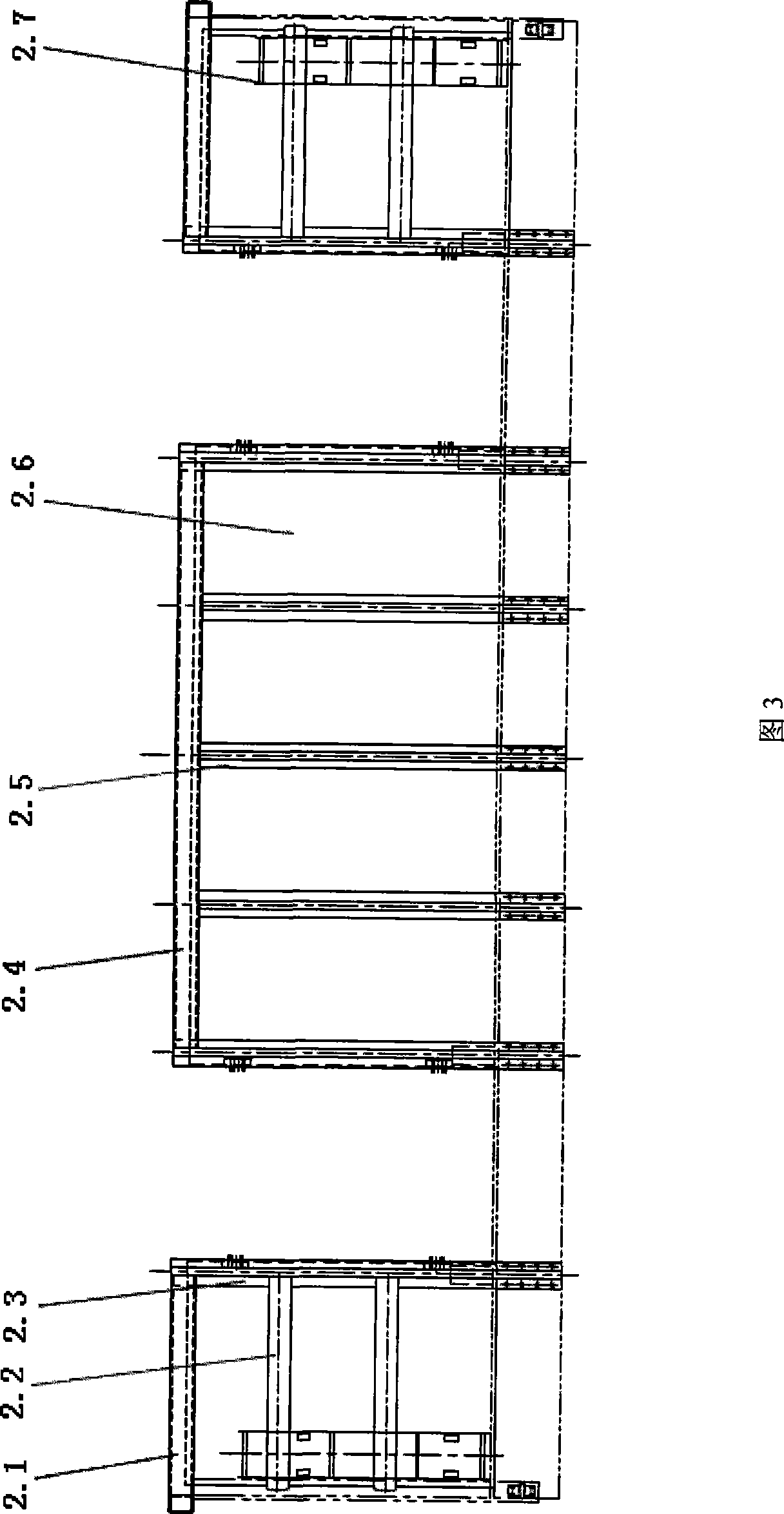

[0024] As shown in Figures 1 to 11, a general-purpose gondola car includes a car body, a bogie 2, a wind hand brake device 5, a safety chain 6 and a coupler buffer device 7, and the car body includes an underframe 1, a car door 3, a side wall 4 and an end wall8.

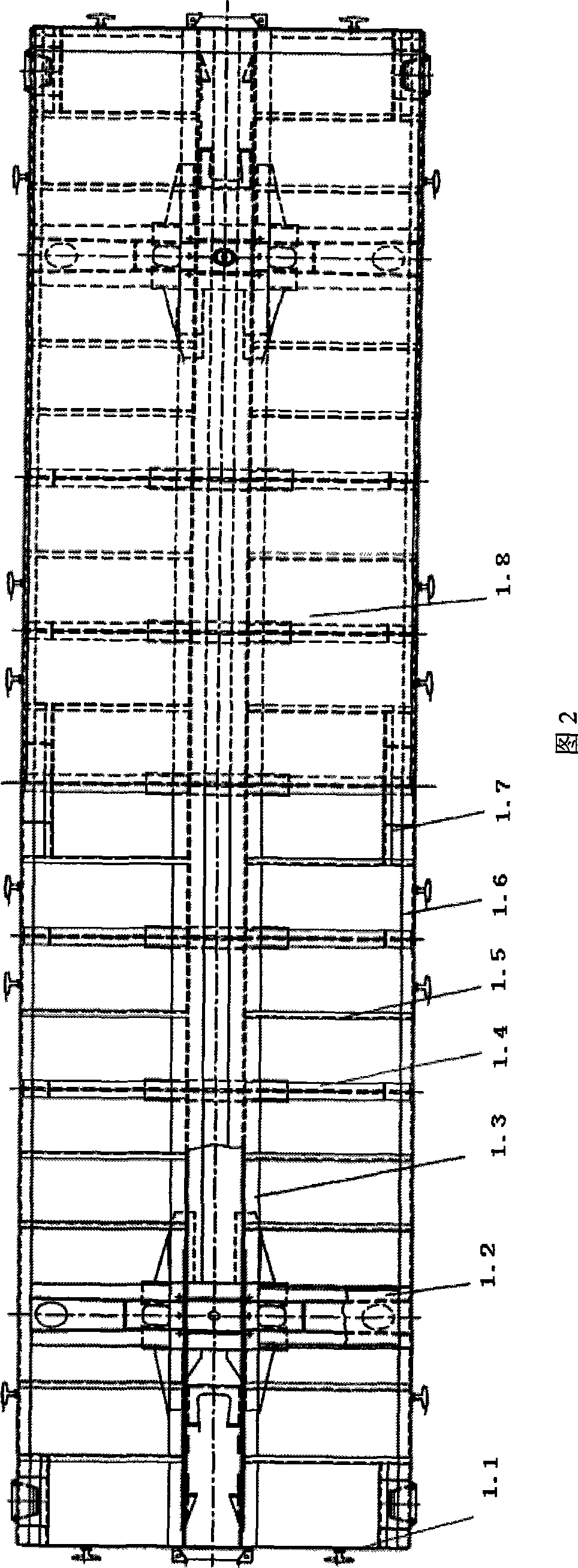

[0025] As shown in Figure 2, the underframe 1 includes a middle beam 1.3, a lower side beam 1.6, a corbel 1.2, an end beam 1.1, a large beam 1.4, a small beam 1.5, a longitudinal beam 1.7 and a floor 1.8. The middle beam is located in the middle of the bottom frame along the longitudinal direction of the bottom frame. As can be seen from Figure 7-9, the middle beam 1.3 is welded by two section steels with "I" shaped sections...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com