Polygonal ferrite-acicular ferrite two-phase steel plate/belt and production method thereof

A polygonal ferrite and acicular ferrite technology, which is applied in the direction of temperature control, etc., can solve the problems of poor impact toughness of dual-phase steel, softening of welds, use restrictions, poor welding performance, etc., and achieves large plastic deformation capacity, high Low temperature toughness level, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] "Fine-grained polygonal ferrite + acicular ferrite" dual-phase structure steel plate, its composition raw materials are calculated in terms of mass percentage: C: 0.05wt%, Si: 0.3 wt%, Mn: 1.5wt%, Nb: 0.045 wt% %, Mo: 0.12 wt%, P: 0.01 wt%, S: 0.0020 wt%, the balance is Fe and unavoidable impurities, which are smelted in a converter and continuously cast into a 300mm billet.

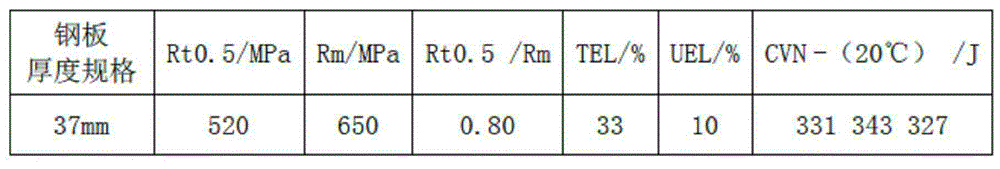

[0029] The cast slab is heated at 1200°C, the heat preservation period is more than 2 hours, the starting rolling temperature is 1100°C, the rough rolling and finishing rolling temperature is 980°C, the cumulative deformation at this temperature is 32%, the thickness of the intermediate billet is 140mm, and the finishing rolling is carried out at 930°C. 790°C, the thickness of the finish-rolled exit steel plate is 37mm; after air cooling to 740°C, start cooling to 500°C at a cooling rate of 15°C / S, and finally air cooling to room temperature.

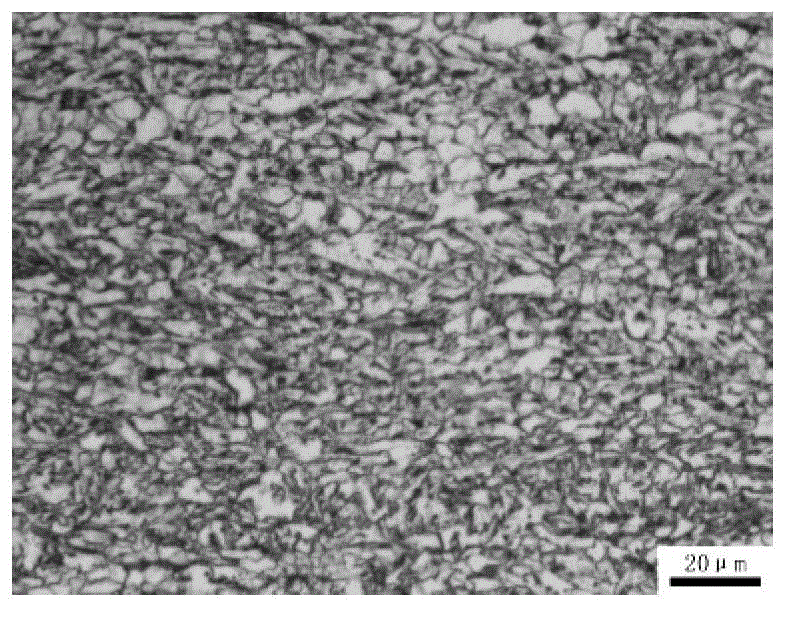

[0030] After testing, the microstructure type of the ...

Embodiment 2 and Embodiment 3

[0035] "Fine-grained polygonal ferrite + acicular ferrite" dual-phase structure hot-rolled steel strip, the composition of raw materials in terms of mass percentage is: C: 0.08wt%, Si: 0.6wt%, Mn: 1.4wt%, Nb : 0.03 wt%, Mo: 0.1 wt%, P: 0.01 wt%, S: 0.0020 wt%, the balance is Fe and unavoidable impurities, smelted by converter, continuous casting into 200mm billet.

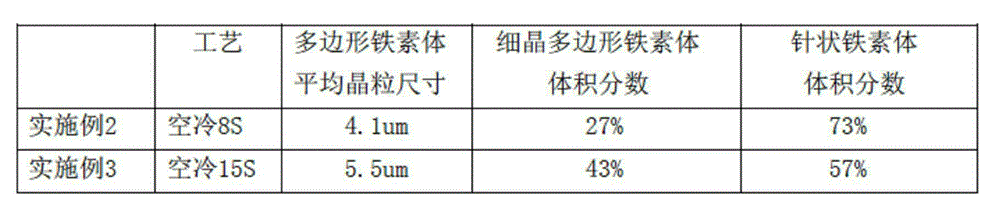

[0036]The cast slab is heated at 1200°C, the holding period is more than 2 hours, the starting rolling temperature is 1100°C, the rough rolling and finishing rolling temperature is 1020°C, the finishing rolling is carried out at 920°C, the finishing rolling temperature is 820°C, the thickness of the finishing rolling exit steel strip is 6mm; After the rolling mill, first accelerate cooling to 710°C, then air-cool for 8S and 15S respectively, and then start to cool at a cooling rate of 15°C / S to 500°C for coiling.

[0037] After testing, the microstructure type of the steel strip is "fine-grained polygonal ferrite +...

Embodiment 4

[0044] "Fine-grained polygonal ferrite + acicular ferrite" dual-phase structure steel strip, its composition raw materials are calculated by mass percentage: C: 0.065wt%, Si: 0.3 wt%, Mn: 1.9wt%, Nb: 0.07 wt%, Mo: 0.26 wt%, P: 0.01 wt%, S: 0.0020 wt%, and the balance is Fe and unavoidable impurities, which are smelted in a converter and continuously cast into a 300mm billet.

[0045] The casting billet is heated at 1200°C, the heat preservation period is more than 2 hours, the starting rolling temperature is 1100°C, the rough rolling and finishing rolling temperature is 980°C, the deformation at this temperature is 30%, the thickness of the intermediate billet is 60mm, the finishing rolling is carried out at 950°C, and the finishing rolling temperature is 790 ℃, the thickness of the finish-rolled exit steel plate is 15.3 mm; after air cooling to 750 ℃, it starts to cool at a cooling rate of 15 ℃ / S to 500 ℃ for coiling.

[0046] After testing, the microstructure type of the ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com