Pearlite like high strength low alloy rail steel and producing method thereof

A high-strength, low-alloy, low-alloy steel technology, applied in the furnace type, temperature control, furnace and other directions, can solve the problems of poor rail welding performance, high welding carbon equivalent, deteriorated rail performance, etc., to achieve excellent welding performance, toughness and Good plasticity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

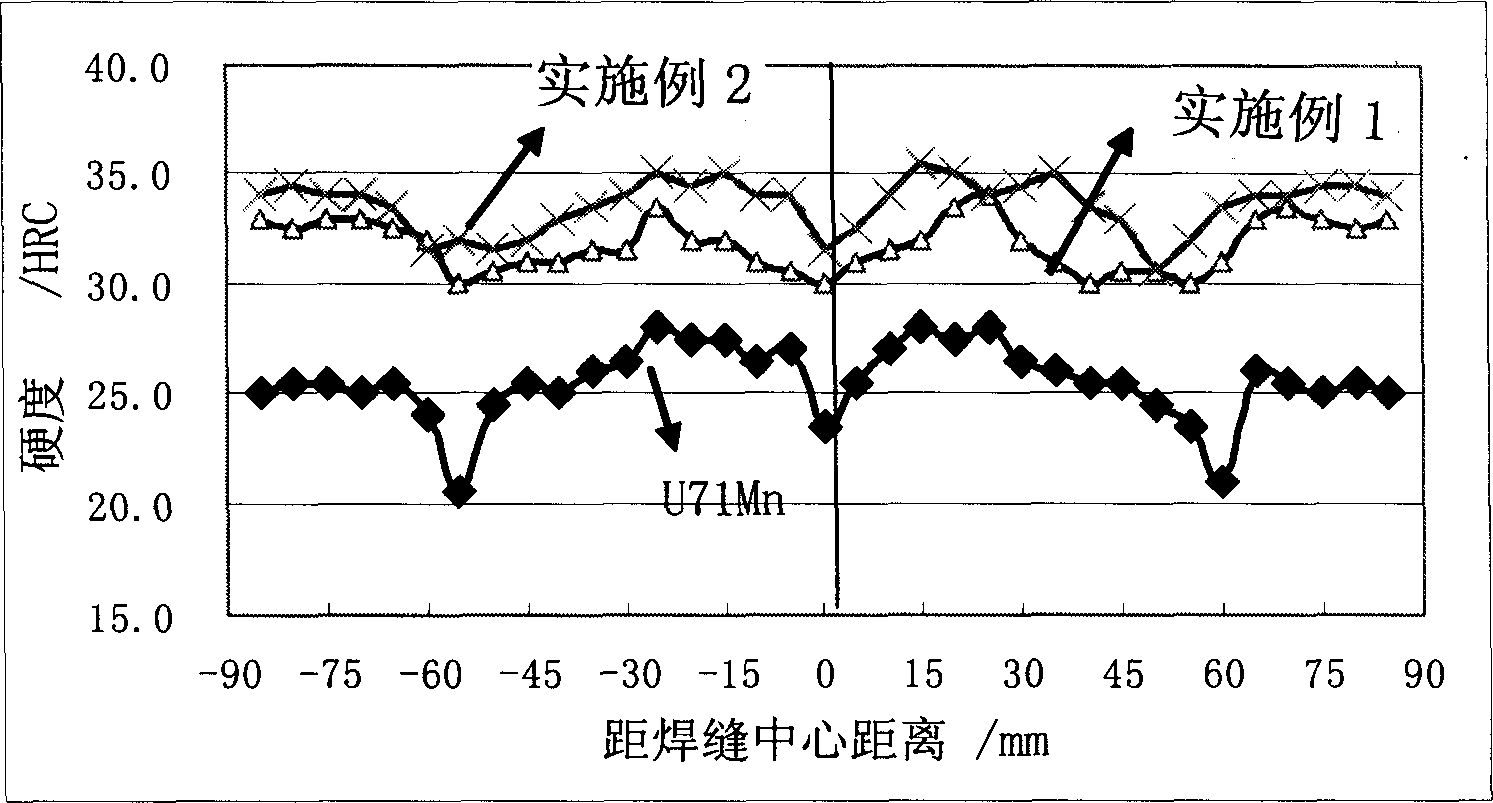

[0044] Table 1 and Table 2 are the chemical composition, corresponding hardness, wear amount, fatigue limit and critical cooling rate results after austenitizing at 1300°C of the rail steels of the present invention from Examples 1 to 10 and the comparison rail U71Mn.

[0045] chemical composition

Example 1

Example 2

Example 3

Example 4

Example 5

C

0.70

0.78

0.84

0.95

0.80

Si

0.65

0.70

0.80

0.65

0.70

mn

0.65

0.81

0.50

0.63

0.85

P

0.018

0.017

0.025

0.017

0.022

S

0.012

0.015

0.010

0.022

0.023

Cr

0.81

0.51

0.46

0.30

0.35

V

0.07

0.08

0.06

0.04

0.05

Mo

0.08

Al

≤0.005

≤0.005

≤0.005

≤0.005

≤0.005

Mn+2Cr+5Mo+3Nb

2.27

1.82

1.42

1.23

1.95

Tensile strength Rm...

Embodiment 11

[0063] 1) The molten iron with a C content of 4.31% is blown by top blowing oxygen for 23 minutes, and the C content is 0.18% when tapping. Add carburizer when tapping, control the carbon content in the ladle above 0.65%, add alloy in the ladle for alloying, the aluminum content of the added alloy is less than 0.8%, and the weight percentage of its chemical composition is: C: 0.78 %, Si: 0.70%, Mn: 0.85%, P: 0.015%, S: 0.011%, V: 0.07%, Cr: 0.51%, Ti: 0.01%, Al≤0.005%.

[0064] 2) After 15 minutes of vacuum treatment, the hydrogen content of the molten steel is 1.1 ppm, and the hydrogen content of the finished rail is 0.9 ppm.

[0065] 3) The soaking temperature of the continuous casting slab is controlled at 1250°C.

[0066] 4) The atmosphere in the furnace is controlled as a weak reducing atmosphere, and the excess air coefficient is controlled between 0.92 and 0.98. Samples are taken from the finished rail, and the decarburized layer of the rail is 0.20mm.

[0067] 5) Wh...

Embodiment 12

[0077] 1) The molten iron with a C content of 4.31% is blown by top blowing oxygen for 23 minutes, and the C content is 0.18% when tapping. Add carburizer when tapping, control the carbon content in the ladle above 0.65%, add alloy in the ladle for alloying, the aluminum content of the added alloy is less than 0.8%, and the weight percentage of its chemical composition is: C: 0.78 %, Si: 0.70%, Mn: 0.85%, P: 0.015%, S: 0.011%, V: 0.07%, Cr: 0.51%, Ti: 0.01%, Al≤0.005%.

[0078] 2) After 15 minutes of vacuum treatment, the hydrogen content of the molten steel is 1.1 ppm, and the hydrogen content of the finished rail is 0.9 ppm.

[0079] 3) The soaking temperature of the continuous casting slab is controlled at 1220°C.

[0080] 4) The atmosphere in the furnace is controlled as a strong oxidizing atmosphere, and the excess air coefficient is controlled between 1.23 and 1.35. Sampling in the finished rail, the rail decarburization layer is 0.24mm.

[0081] 5) When the rail is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com