Heat treatment process of AISI4340 steel forgings

A steel forging and process technology, which is applied in the field of heat treatment process of AISI4340 steel forging, can solve the problems of poor low temperature impact toughness and inability to meet the requirements of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

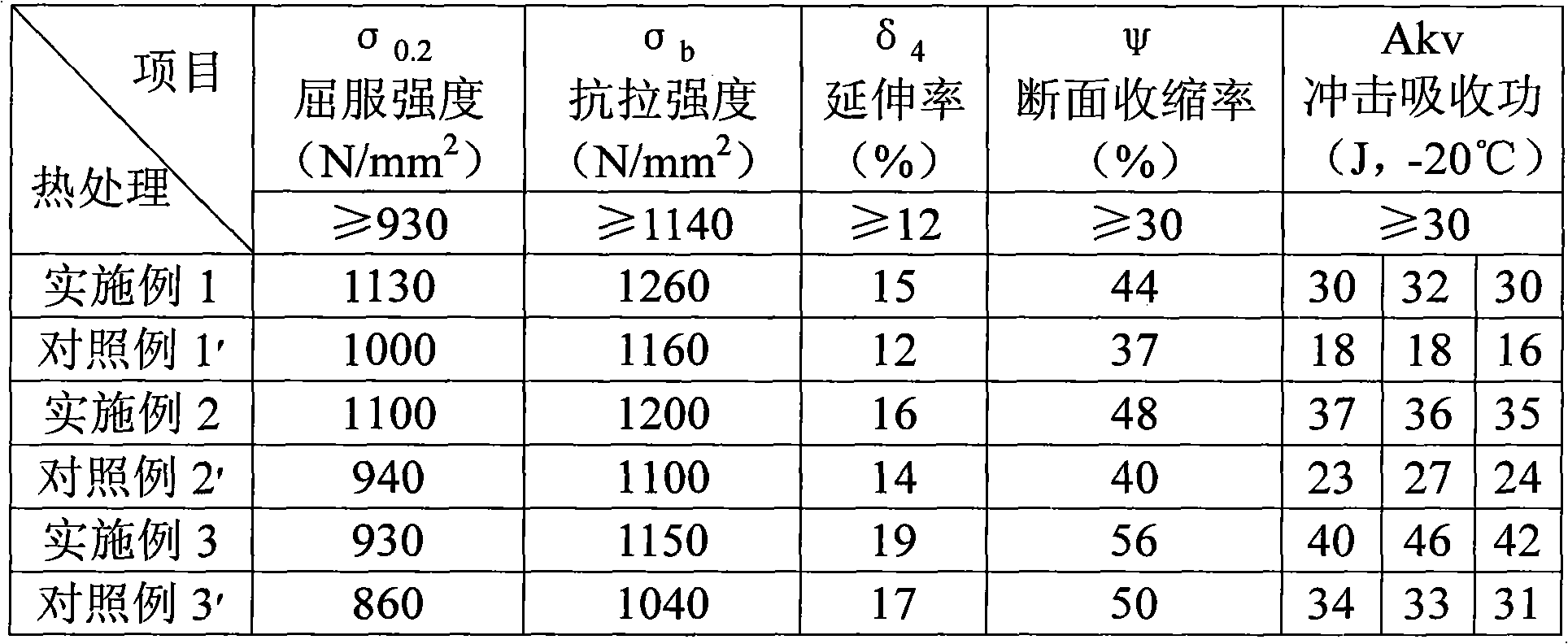

Examples

Embodiment 1

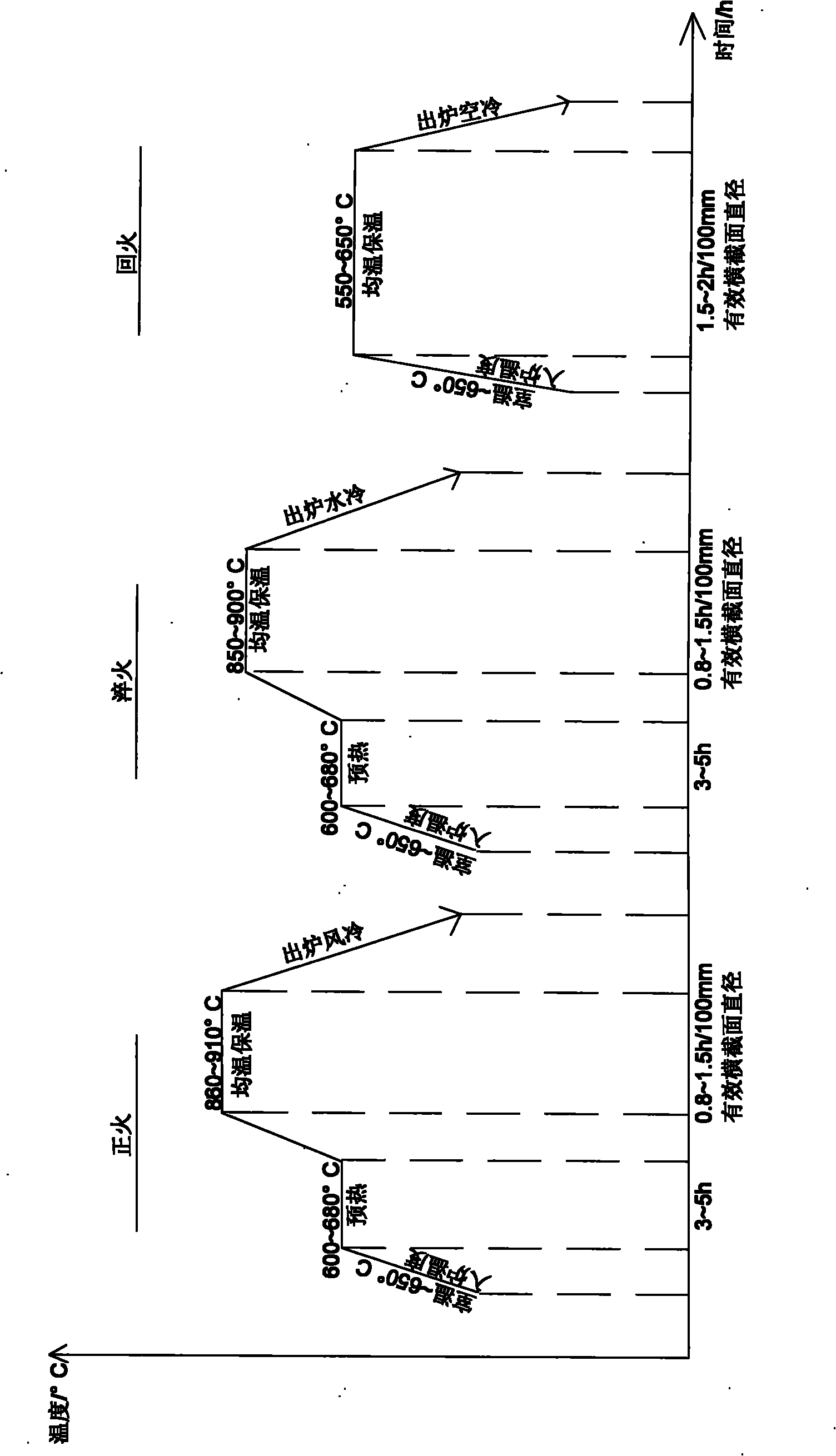

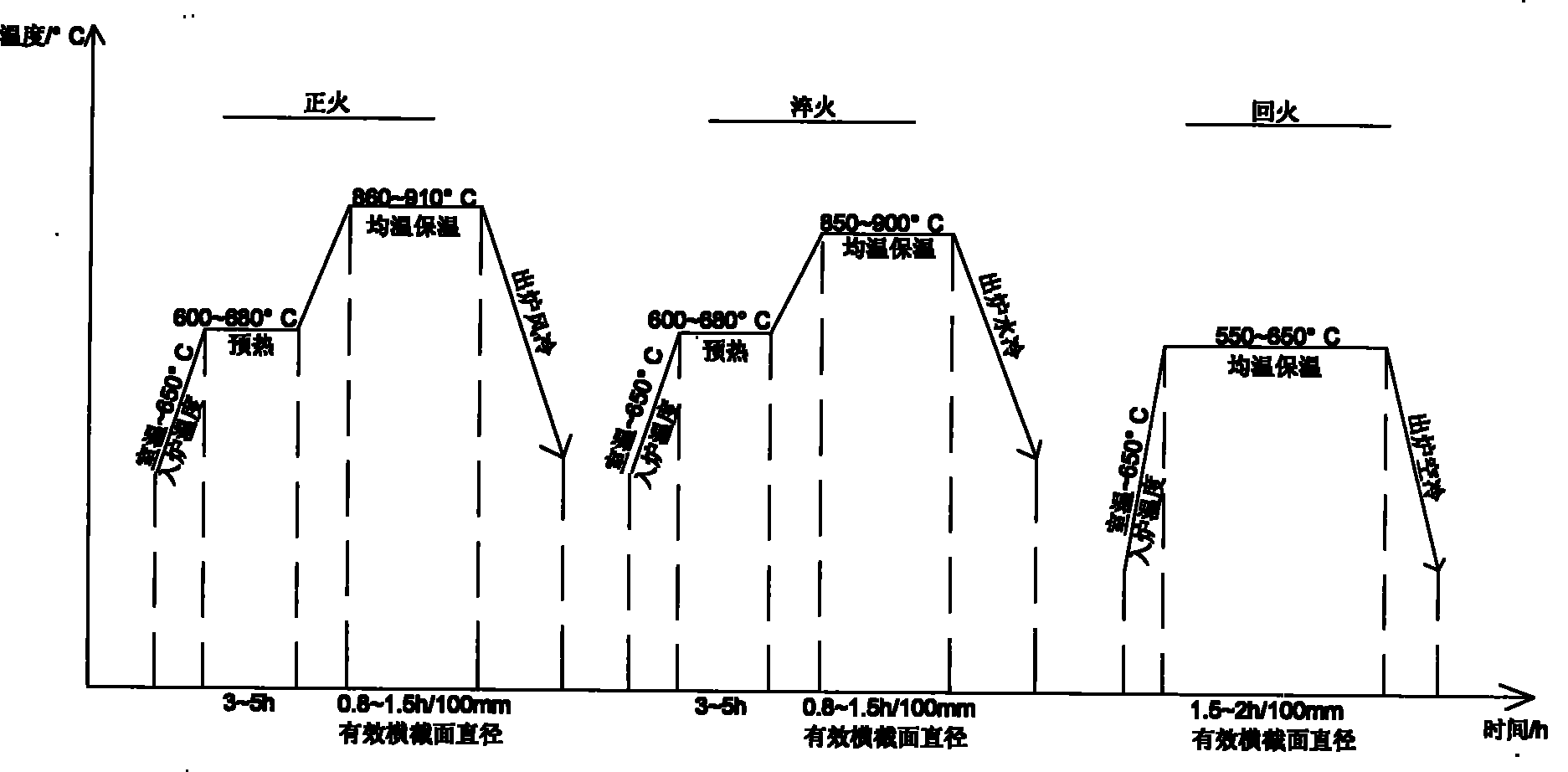

[0021] As shown in the accompanying drawing, a heat treatment process of AISI 4340 steel forgings, the heat treatment process is:

[0022] (1) Normalizing treatment to complete austenite transformation: AISI 4340 steel forgings are put into the furnace at room temperature, preheated to 600°C, preheated and kept for 3 hours to eliminate internal stress, and then heated to normal at a rate of 20°C / h The fire temperature is 860°C, heat preservation (1h per 100mm AISI 4340 steel forging effective cross-sectional diameter) until the core of AISI 4340 steel forging reaches the normalizing temperature to complete the structure transformation and homogenization, and the axial flow fan is used for forced cooling when the furnace is released, and the blower is improved. The height of the base makes it aligned with the AISI 4340 steel forging, and four axial flow fans are placed on both sides of the upper and lower clamping platforms, blowing directly onto the AISI 4340 steel forging from...

Embodiment 2

[0028] As shown in the accompanying drawing, a heat treatment process of AISI 4340 steel forgings, the heat treatment process is:

[0029] (1) Normalizing treatment to complete austenite transformation: AISI 4340 steel forgings are put into the furnace at a temperature of 350°C, preheated to 640°C, preheated and kept for 4 hours to eliminate internal stress, and then heated at a rate of 50°C / h to The normalizing temperature is 890°C, heat preservation (effective cross-sectional diameter of 100mm AISI 4340 steel forgings is 0.9h) until the core of AISI 4340 steel forgings reaches the normalizing temperature to complete the structural transformation and homogenization, and the furnace is forced to cool by axial flow fan blasting. Raise the height of the base of the axial flow fan to align it with the AISI 4340 steel forging, place four blowers on both sides of the upper and lower clamping platforms, and blow directly onto the AISI 4340 steel forging from multiple directions, forc...

Embodiment 3

[0035] As shown in the accompanying drawing, a heat treatment process of AISI 4340 steel forgings, the heat treatment process is:

[0036] (1) Normalizing treatment to complete austenite transformation: AISI 4340 steel forgings are put into the furnace at a temperature of 650°C, preheated to 680°C, preheated and kept for 5 hours to eliminate internal stress, and then heated at a rate of 80°C / h to Normalizing temperature is 910°C, heat preservation (effective cross-sectional diameter of AISI 4340 steel forgings is 0.8h per 100mm) until the core of AISI 4340 steel forgings reaches the normalizing temperature to complete structural transformation and homogenization. Raise the height of the blower base so that it is aligned with the AISI 4340 steel forging, place four blowers on both sides of the upper and lower clamping platforms, and blow directly onto the AISI 4340 steel forging from multiple directions, forcing the entire AISI 4340 steel forging to cool evenly and rapidly to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com