High-strength and high-toughness spring steel and manufacturing method thereof

A manufacturing method and high-toughness technology, applied in the field of spring steel and its manufacturing, can solve the problems of high production cost, large amount of alloy added, etc., and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A10

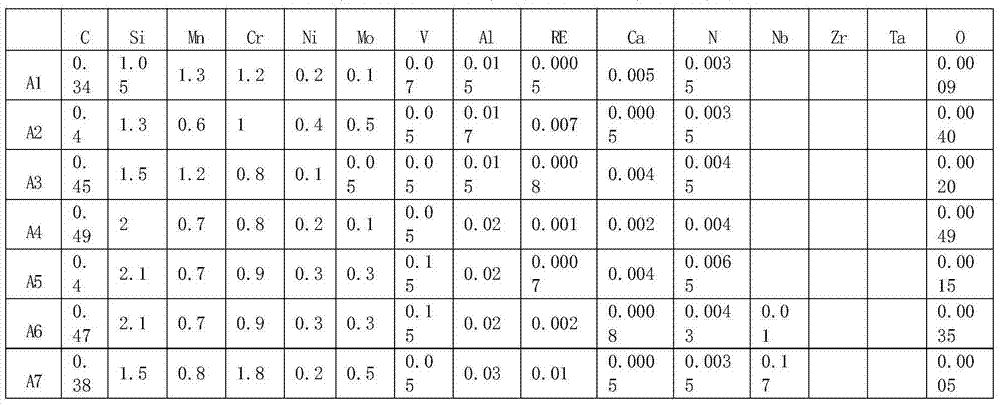

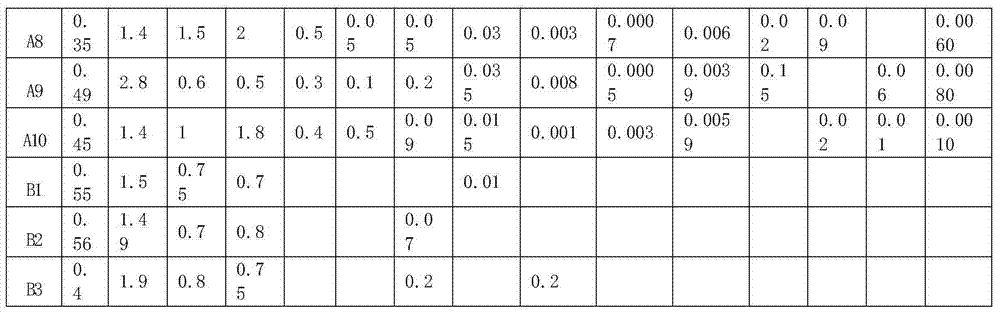

[0069] Follow the steps below to manufacture high-strength and high-toughness spring steel, and control the mass distribution of its chemical elements as shown in Table 1:

[0070] 1) Smelting: Examples A1-A5 use electric furnace smelting, Examples A6-A10 use converter smelting, and then perform out-of-furnace refining, where Examples A1-A6 use LF furnace plus VD refining, and Examples A7-A10 use LF Add RH treatment, adjust the composition and amount of synthetic slag in the smelting process, control the content of P and S elements in the steel to be less than 0.010%, carry out argon stirring, control the vacuum degassing time to 25-40 minutes, and control the end point O content to be lower than 80ppm, N content is less than 65ppm, H content is less than 2ppm, alloying elements are added after full deoxidation, RE and Ca elements are added for sedation before tapping, to further improve the purity of steel and carry out inclusion modification treatment;

[0071] 2) Casting: use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com