Double-ferrule type pipe joint of double-sealing and double-fastening support and using method thereof

A double-seal and ferrule-type technology, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing components, etc., can solve the problems of poor sealing performance, edge cracking and peeling, low connection strength, etc., and reach the surface Increased strength, good performance in repeated disassembly and assembly, and improved self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

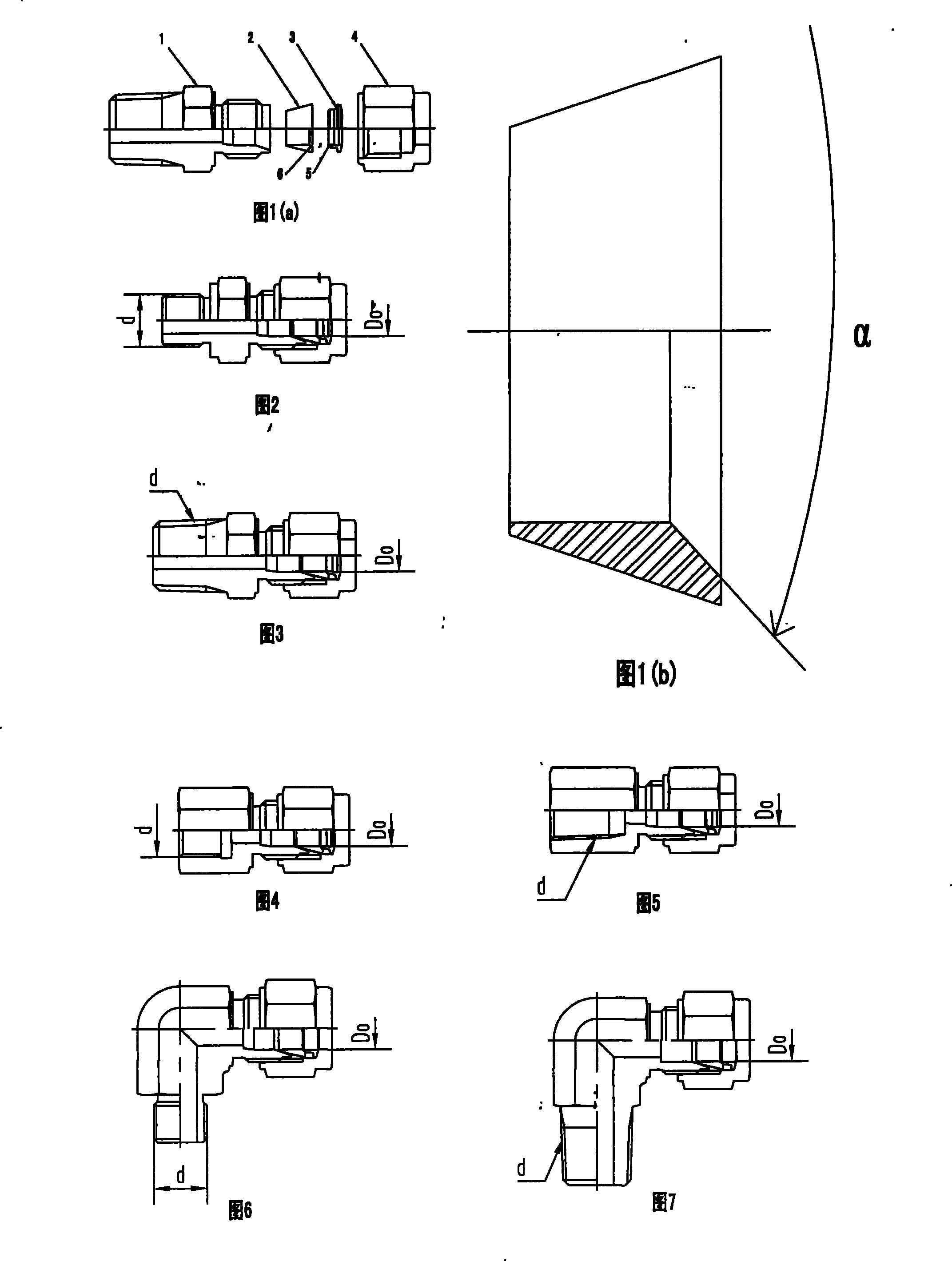

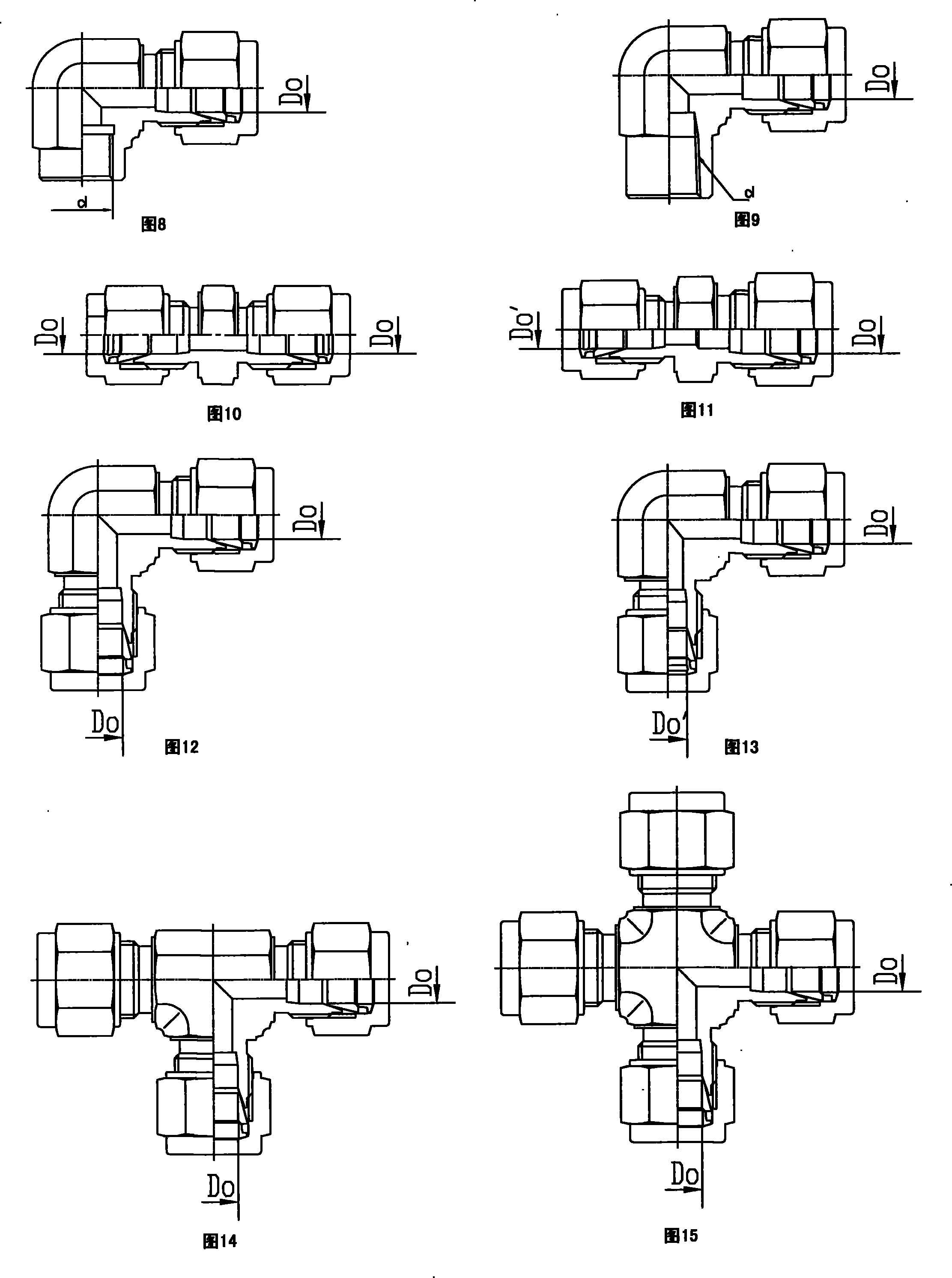

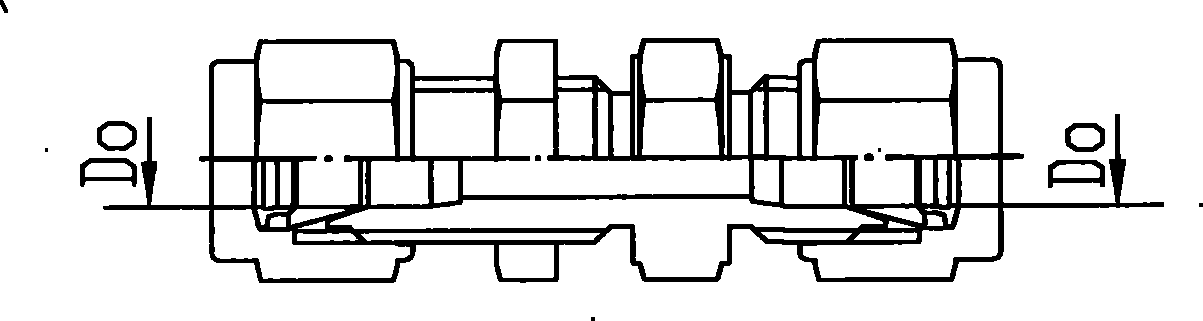

[0050] As shown in Figure 1, the double ferrule pipe joint of the present invention is a compact sealing and tightening device composed of a joint body 1, a front ferrule 2, a rear ferrule 3 and a nut 4. The joint body 1 and the nut 4 Through threaded connection, the front ferrule 2 and the rear ferrule 3 are installed between the joint body 1 and the nut 4 in sequence. The sleeve 3 is a ring with a flange, the flange end of the rear ferrule 3 fits with the inner surface of the nut, the front outer cone surface 5 of the other end of the rear ferrule 3 and the rear inner cone surface 6 of the front ferrule 2 pass through the cone surface In cooperation, the rear inner taper angle α of the front ferrule 2 in this embodiment is 80 degrees. When in use, first insert the pipe into the joint body 1 (be sure to insert the pipe all the way to the bottom), tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com