Ultrahard waterproof membrane and processing technology of ultrahard waterproof membrane

A waterproof film, super-hard technology, used in optics, instruments, optical components, etc., can solve the problems of complex process and unstable quality, and achieve the effect of firm and uniform film layer and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

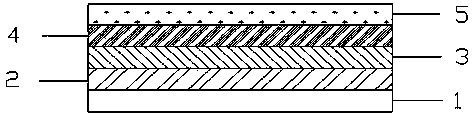

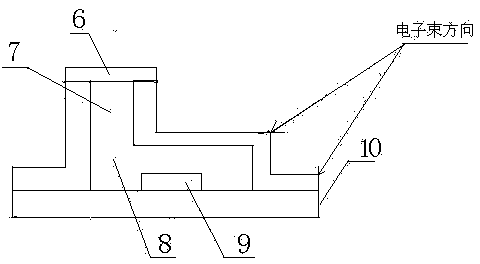

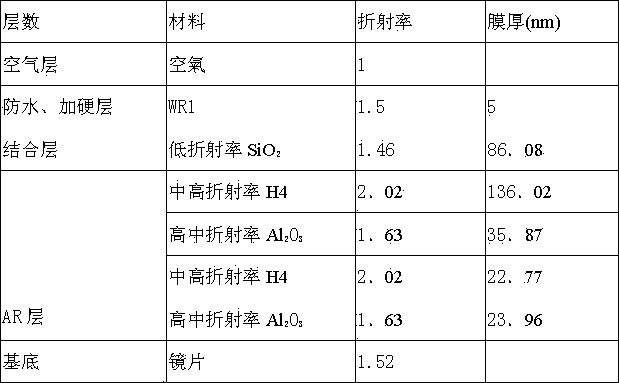

[0027] Depend on figure 1 Known, a super-hard waterproof film, in order from bottom to top is an optical glass lens 1, an anti-reflection layer (AR layer) 2, a bonding layer 3, a waterproof hard layer 4 and an air layer 5, the AR layer 2 The H4 film material with a high and high refractive index of 2.02 and a film thickness of 136.02 (nm) in the first layer, and Al with a high and high refractive index of 1.63 and a film thickness of 35.87 (nm) in the second layer 2 o 3 Film material, H4 film material with middle and high refractive index of 2.02 in the third layer and film thickness of 22.77 (nm), Al in the fourth layer with high refractive index of 1.63 and film thickness of 23.96 (nm) 2 o 3 Composition, the optical glass lens 1 is K9 optical glass with a refractive index of 1.52, and the bonding layer 3 is MgF with a low refractive index of 1.46 and a film thickness of 86.08 (nm). 2 or SiO 2 Membrane material, the waterproof and hardened layer 4 is a WR1 waterproof memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com