Alkali-free liquid concrete accelerator and preparation method and application of alkali-free liquid concrete accelerator

A concrete and quick-setting agent technology, applied in the field of quick-setting agent, can solve the problems of high alkalinity of the product, unsatisfactory sprayed concrete, and difficult concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

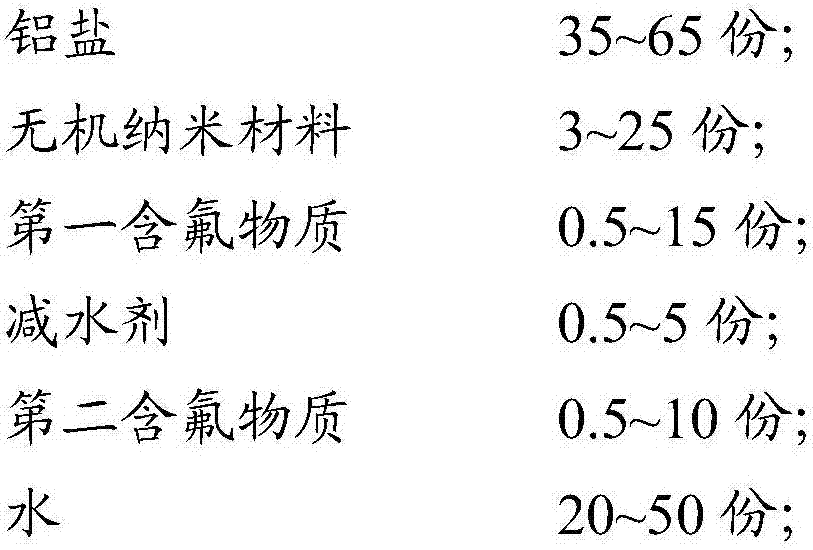

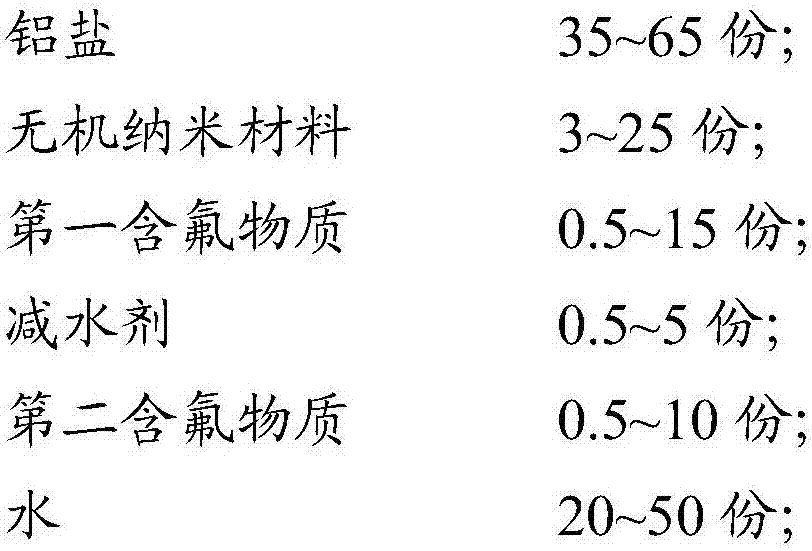

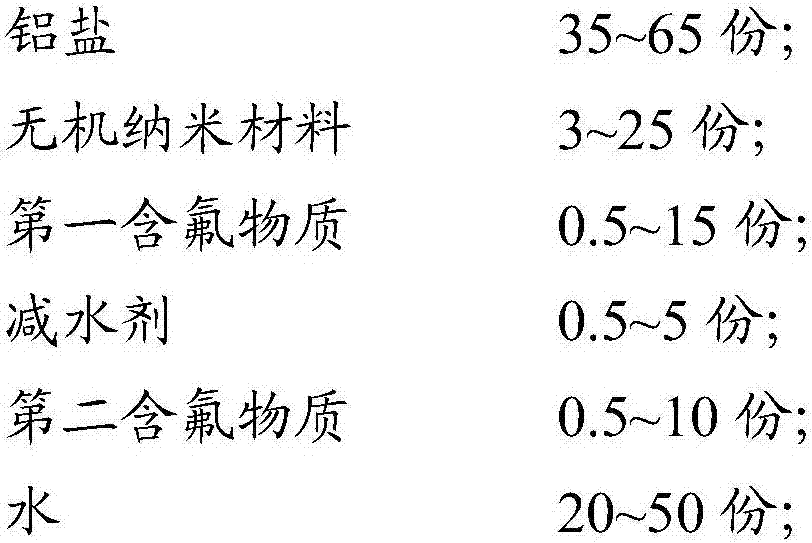

[0034] The present invention provides the preparation method of alkali-free liquid concrete quick-setting agent described in above-mentioned scheme, comprises the following steps:

[0035] The aluminum salt, the inorganic nanometer material, the first fluorine-containing substance, the water reducing agent, the second fluorine-containing substance and water are mixed and then stirred for 2-8 hours to obtain the alkali-free liquid concrete quick-setting agent.

[0036] In the present invention, it is preferable to add the nanomaterial, the first fluorine-containing substance, the water reducing agent, and the second fluorine-containing substance into the water, and then add the aluminum salt after stirring evenly; There is no special requirement on the order of adding the agent and the second fluorine-containing substance, and any order of addition can be adopted.

[0037] In the present invention, after the above raw materials are mixed, they are stirred for 2-8 hours to obtai...

Embodiment 1

[0042] An alkali-free liquid concrete accelerator, comprising the following components in parts by mass: 50 parts of aluminum sulfate, 10 parts of acidic silica sol, 3 parts of sodium fluoride, 1 part of nonionic polyacrylamide, and 4 parts of magnesium fluorosilicate part, 32 parts of water;

[0043] Add water into the stainless steel reaction kettle according to the above ratio, then add acidic silica sol, sodium fluoride, non-ionic polyacrylamide and magnesium fluorosilicate to the water according to the above ratio, stir evenly, add aluminum sulfate, continue to stir for 5h, stir The rotation speed is 350r / min, and the stirring temperature is 25°C to obtain an alkali-free liquid concrete quick-setting agent.

Embodiment 2

[0045] An alkali-free liquid concrete quick-setting agent, comprising the following components in parts by mass: 50 parts of aluminum sulfate, neutral silica sol (SiO 2 The content is 30wt%, the particle size is 8nm) 10 parts, sodium fluoride 3 parts, non-ionic polyacrylamide 1 part, magnesium fluorosilicate 4 parts, water 32 parts;

[0046] Add water into the stainless steel reaction kettle according to the above ratio, then add acidic silica sol, sodium fluoride, non-ionic polyacrylamide and magnesium fluorosilicate to the water according to the above ratio, stir evenly, add aluminum sulfate, continue to stir for 8 hours, stir The rotation speed is 150r / min, and the stirring temperature is 10°C to obtain an alkali-free liquid concrete quick-setting agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com