Anti-freezing alkali-free liquid accelerator and preparation method thereof

A technology of freezing and quick-setting agent, which is applied in the field of anti-freezing non-alkali liquid quick-setting agent and its preparation. It can solve the problems of large loss of concrete strength in the later stage, not being an alkali-free quick-setting agent, and high production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

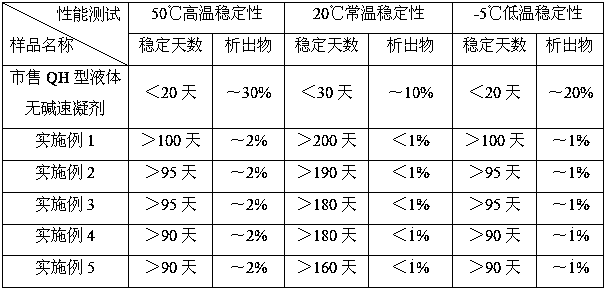

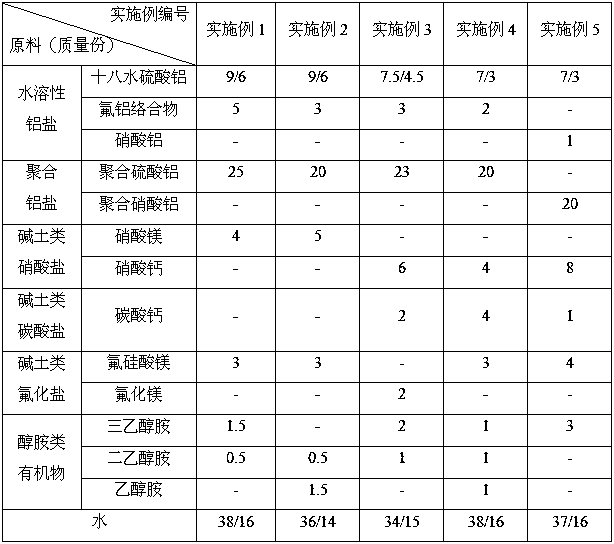

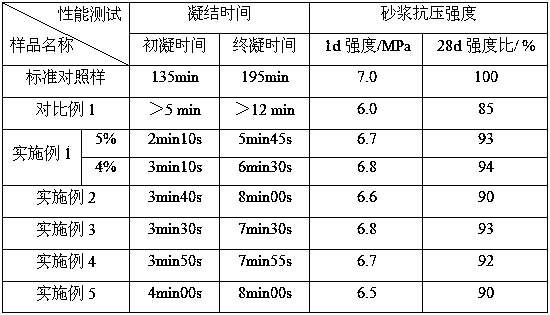

[0043] A kind of antifreeze type non-alkali liquid quick-setting agent embodiment 1~5

[0044] A kind of antifreeze type non-alkali liquid quick-setting agent embodiment 1~5 raw material components and proportioning ratio are shown in Table 1:

[0045] Table 1 Raw material components and proportioning table of Examples 1-5 of an antifreeze type non-alkali liquid accelerator

[0046]

[0047] Note: "-" in the table means no addition; the numbers before and after " / " in aluminum sulfate octadecahydrate and water indicate the amount added successively.

Embodiment 1

[0049] According to the mass parts of each raw material described in Table 1, Example 1, first dissolve the fluoroaluminum complex and a part of aluminum sulfate octadecahydrate with a part of water, then heat and stir at 70°C and 100r / min until dissolved, then add polymeric sulfuric acid Aluminum and magnesium nitrate, heat and react at 70°C for 2 hours, cool to room temperature, then add magnesium fluorosilicate, alcohol amine organic substances (triethanolamine and diethanolamine) and the remaining part of aluminum sulfate octadecahydrate, and finally add the remaining part water, filter and serve.

Embodiment 2

[0051] According to the mass parts of the raw materials described in Table 1, Example 2, first dissolve the fluoroaluminum complex and a part of aluminum sulfate octadecahydrate with a part of water, then heat and stir at 80°C and 60r / min until dissolved, then add polymeric sulfuric acid Aluminum and magnesium nitrate, heat and react at 80°C for 1.5h, cool to room temperature, then add magnesium fluorosilicate, alcohol amine organic substances (diethanolamine and ethanolamine) and the remaining part of aluminum sulfate octadecahydrate, and finally add the remaining part water, filter and serve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com