Heat treatment technology for pearlite steel rail hardening

A pearlitic rail and process technology, used in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., to achieve the effect of hardening and strong operability

Inactive Publication Date: 2016-04-13

INNER MONGOLIA BAOTOU STEEL UNION

View PDF3 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Cool to 700-500°C, with a difference of 200°C. If the temperature is higher, there will be more ferrite in the structure, and the hardening effect may not be achieved. If the temperature is lower, bainite or martensite may appear in the structure, which will affect the rail. overall service performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

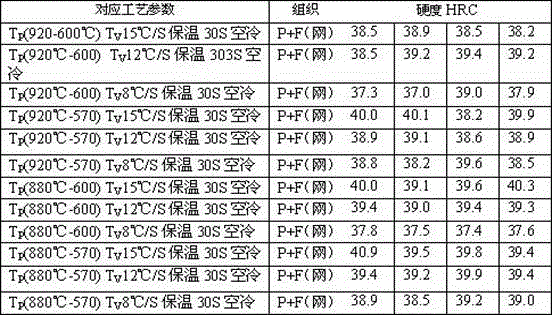

[0012] Example 1: U75V pearlitic steel rail

[0013]

Embodiment 2

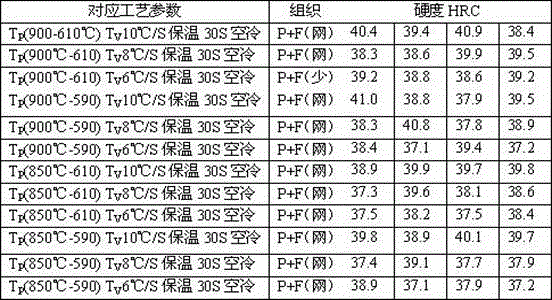

[0014] Example 2: U76CrRE pearlitic steel rail

[0015]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a heat treatment technology for pearlite steel rail hardening. The heat treatment technology for pearlite steel rail hardening is characterized in that a steel rail is heated to 880 DEG C to 920 DEG C, the temperature is kept for 10 minutes to 15 minutes, according to the different types of steel, the temperature is decreased to be within the specific temperature interval according to the specific cooling speed range and is kept for 30 seconds, and air cooling is conducted; the air cooling includes the specific steps that according to the pearlite steel rail hardening process system adopting a U75 V material, the temperature ranging from 880 DEG C to 920 DEG C is kept for 10 minutes to 15 minutes, the temperature is decreased to 570 DEG C to 600 DEG C with the cooling speed being 8 DEG C / s to 15 DEG C / s, and then the temperature is decreased to 20 DEG C to 25 DEG C with the cooling speed being 0.2 DEG C / s to 0.5 DEG C / s in an air cooling manner; and according to the pearlite steel rail hardening process system adopting a U76 CrRE material, the temperature ranging from 850 DEG C to 900 DEG C is kept for 10 minutes to 15 minutes, the temperature is decreased to 590 DEG C to 610 DEG C with the cooling speed being 6 DEG C / s to 10 DEG C / s, and then the temperature is decreased to 20 DEG C to 25 DEG C with the cooling speed being 0.2 DEG C / s to 0.5 DEG C / s in an air cooling manner. The heat treatment technology has the advantages that the specific hardening heat treatment technology of steel rails made of certain specific components is standardized, operability is high, optimum matching of the hardening heat treatment technology and the components of the steel rails is achieved, and the hardening effect of the steel rails is achieved.

Description

technical field [0001] The invention belongs to the technical field of rail heat treatment, and in particular relates to a heat treatment process for pearlitic rail hardening. Background technique [0002] The development of the national economy has led to an increase in my country's railway investment year by year, such as increasing from the original plan of 620 billion to 800 billion in 2014. At the same time, the capacity and speed of railways have also increased significantly in recent years, and the requirements for heavy rail performance are also more stringent. [0003] With the gradual development of high-speed and heavy-duty railway transportation, higher requirements are put forward for the strength of the rail and the hardness of the rail head. It is a relatively energy-saving and economical method to improve the strength and tread hardness of rails through rail heat treatment technology. The heat treatment technologies for pearlite rails mainly include full-le...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C21D9/04

CPCC21D9/04

Inventor 李智丽何建中贺景春杨维宇刘莉史文义白雅琼靳燕高峰

Owner INNER MONGOLIA BAOTOU STEEL UNION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com