Construction method for paving-type high-abrasion-resistance alloy terrace

A construction method and a paving-type technology, applied in the field of floor manufacturing, can solve the problems of difficult to eliminate dust, uneven color, affect the appearance, etc., and achieve the effect of enhanced stain resistance and brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

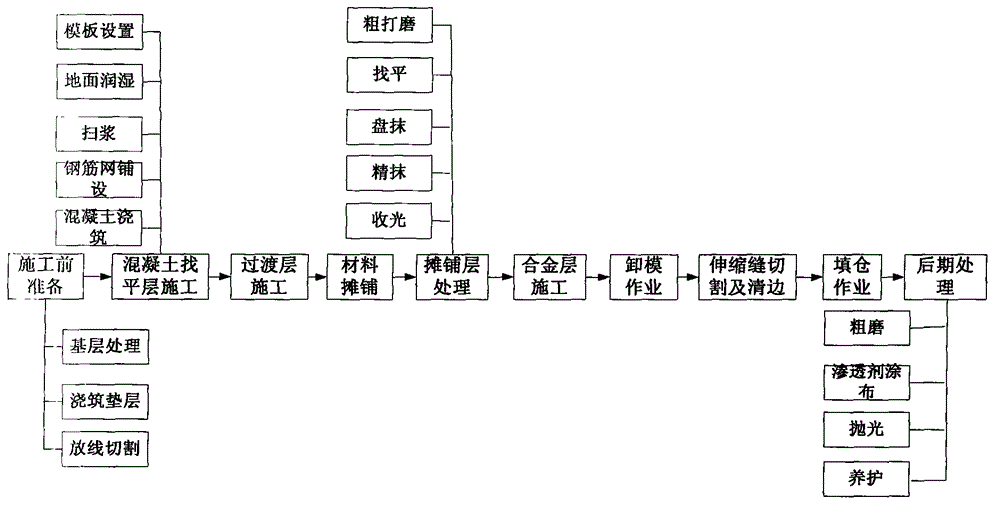

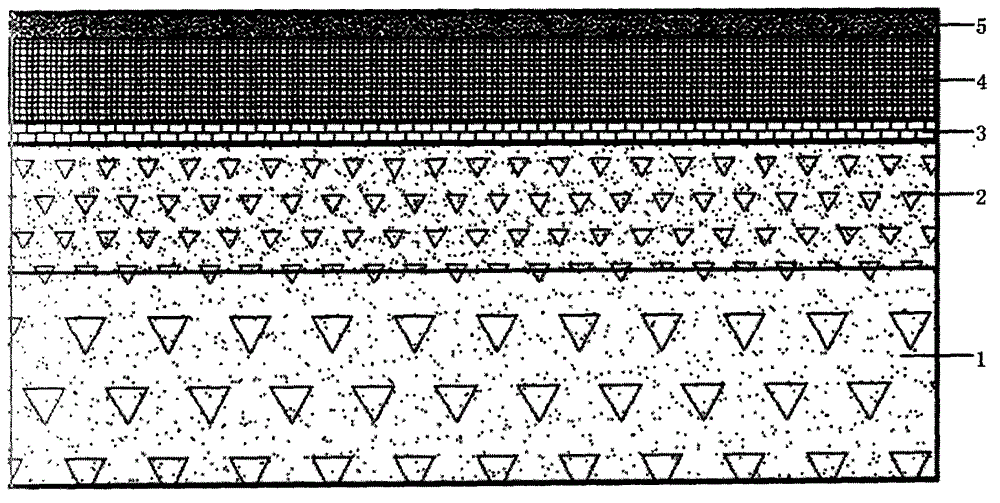

[0037] The construction method of a paving type high wear-resistant alloy floor of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. refer to figure 2 , a paving type high wear-resistant alloy floor of the present invention includes a concrete cushion layer 1, a concrete leveling layer 2, a transition layer 3, a paving layer 4, and an alloy layer 5, and its construction process refers to figure 1 The flow shown:

[0038] 1. Preparation before construction

[0039] 1. Control points for grass-roots treatment: Sprinkle water and moisten the grass-roots. Roll the base layer with a compactor, and tamp the corners with a tamping machine.

[0040] 2. Pouring concrete cushion, grinding and leveling.

[0041] 3. Carry out setting-out cutting according to the site conditions. The north-south setting-out degree is 4 to 6m (it can be slightly adjusted, and the later pouring concrete needs to set up the form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com