Precision investment casting water glass binder shell CO2 gas hardening technology

A technology of investment precision casting and water glass, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. The environment is clean and hardened, and the operating environment is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments.

[0034] The present invention includes the following steps:

[0035] (1) Place the shell to be hardened in a fully sealed hardening chamber;

[0036] (2) Start the vacuum pump to keep the sealed chamber in a vacuum state;

[0037] (3), CO 2 The gas is introduced into the hardening chamber, and the rapid dehumidification system is activated to make the coating layer on the surface of the shell and CO 2 The gas reacts chemically and physically to complete the hardening of the shell;

[0038] (4), close CO 2 Intake valve, start the suction pump, harden the CO in the room 2 Withdraw to the storage tank for recycling.

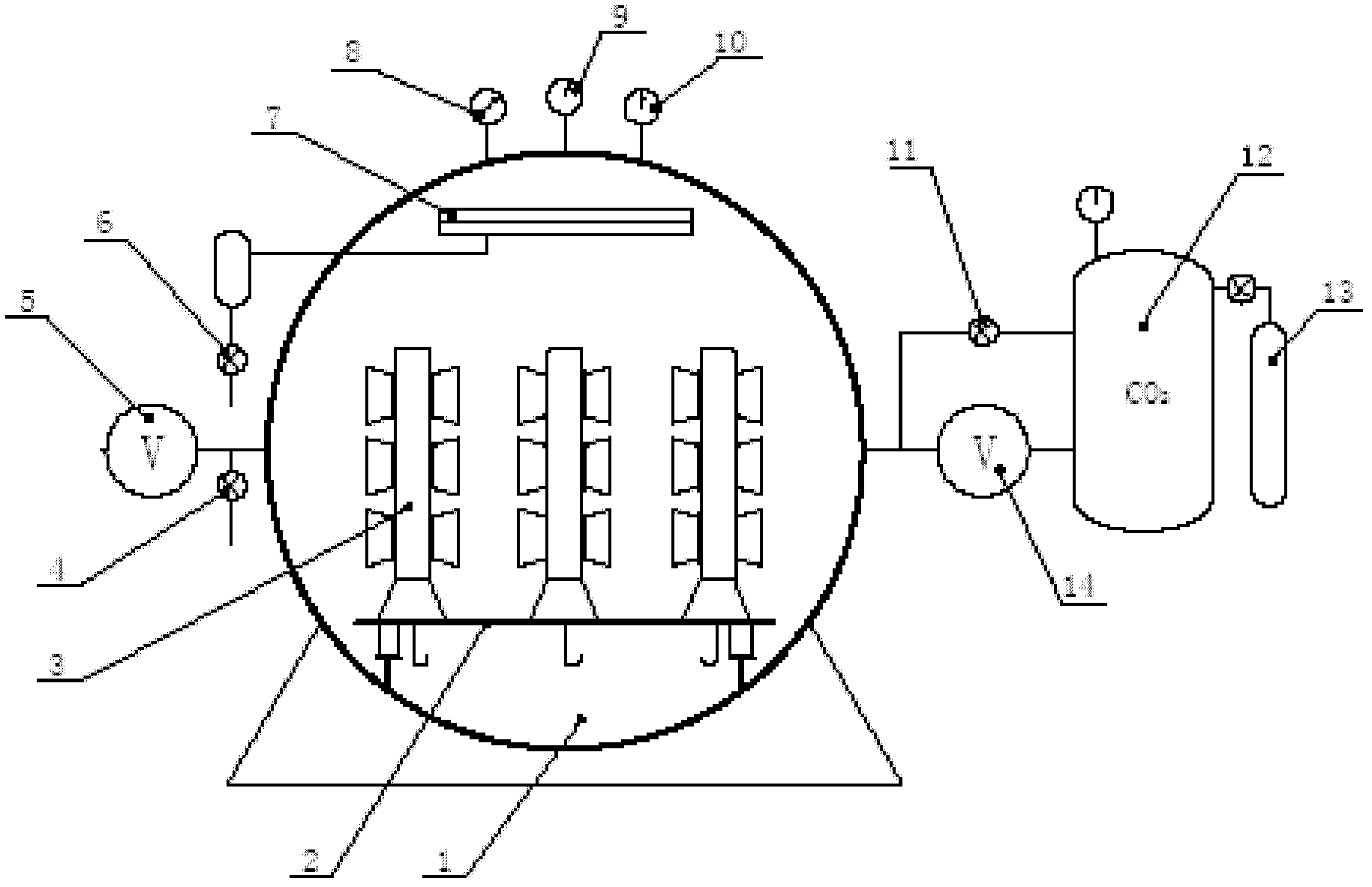

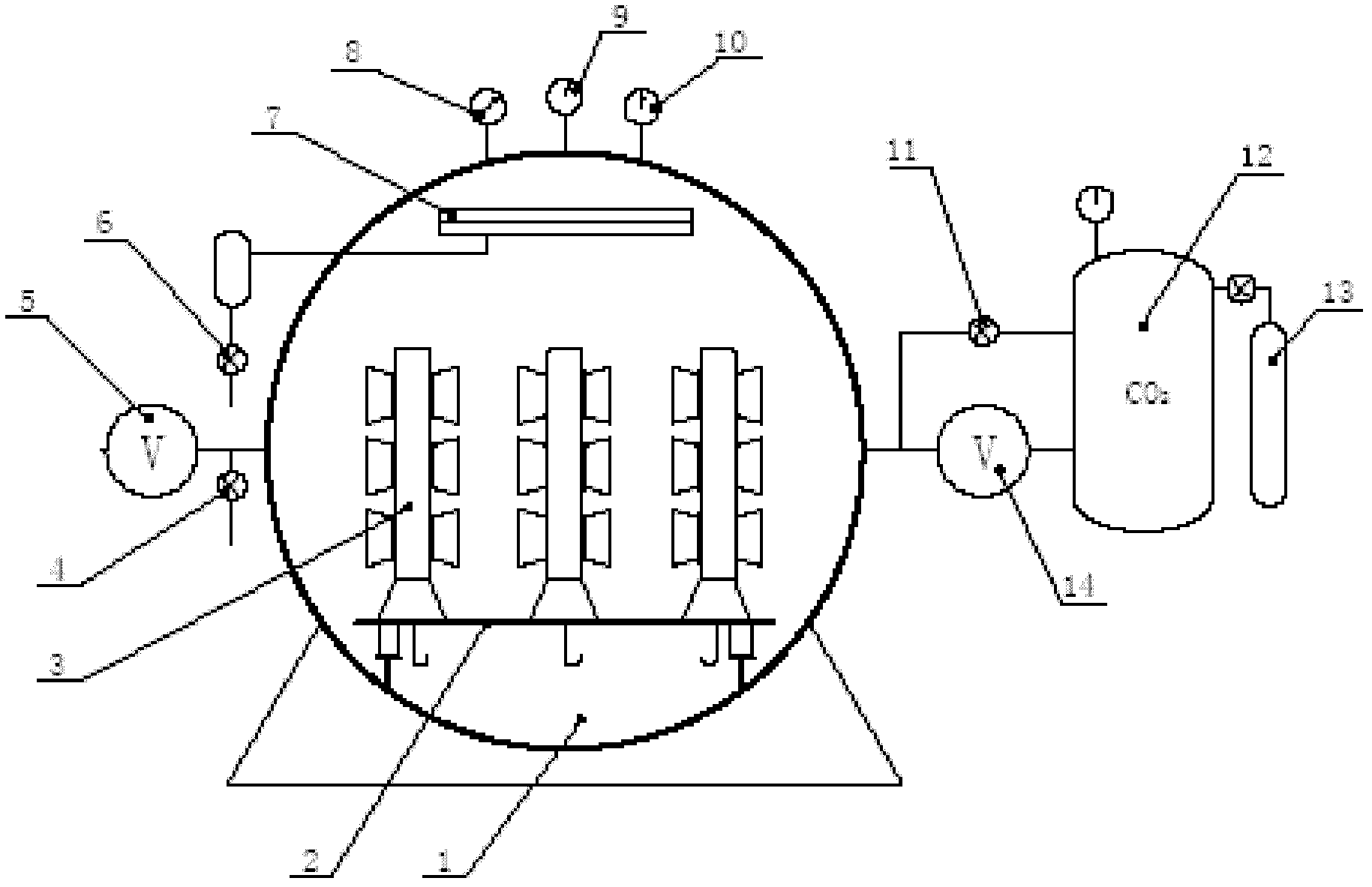

[0039] The invention passes CO 2 Gas hardening device for hardening, such as figure 1 As shown, the CO 2 The gas hardening device includes a fully enclosed hardening chamber 1, in which a mold shell trolley 2 is installed, the mold shell trolley 2 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com