Magnesium alloy having high ductility and high toughness, and preparation method thereof

a technology of ductility and toughness, applied in the field of magnesium alloys having high ductility and high toughness, can solve the problems of low formability, less consideration of magnesium for extended applications in the industries, and limited formability of magnesium alloys, and achieve the effects of high ductility and toughness, precipitation hardening effect, and degradation of ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 11

Preparation of Extruded Magnesium Alloy Material 1 to 11

Step 1. Melting Magnesium Alloy Raw Material

[0087]Using pure Mg(99.9 wt %), pure Sn(99.9 wt %), pure Zn(99.995 wt %), pure Al(99.9 wt %), Mg—Mn master alloy(Mn:3.17 wt %), pure Ce(99.9 wt %), pure Y(99.9 wt %) and pure Gd(99.9 wt %), the magnesium alloy with the composition as listed in Table 2 below was melt in graphite crucible using high frequency induction melting furnace. A mixed gas of SF6 and CO2 was applied to the top of the melt, to prevent oxidization by isolating the melt from possible exposure to air.

TABLE 2Alloying composition(wt %)AlloySnZnAlMnCeYGdMgExample 1TZ2020.5—————Bal.Example 2TZ2121—————Bal.Example 3TZ2222—————Bal.Example 4TZA211211————Bal.Example 5TZA212212————Bal.Example 6TZM21021—0.5———Bal.Example 7TZAM21102110.5———Bal.Example 8TZ21-Ce21——0.5——Bal.Example 9TZ21-Y21———0.5—Bal.Example 10TZ-Gd21————0.5Bal.Example 11TZA211-Gd211———0.5Bal.

Step 2. Casting Magnesium Alloy

[0088]The melt of magnesium alloy of S...

example 12

Preparation of Extruded Magnesium Alloy Material 12

[0091]The extruded magnesium alloy material was prepared in the same manner as Example 2, except for difference that the extruded magnesium alloy material prepared at Example 2 additionally underwent aging treatment at 200° C. for 144 hr.

experimental example 1

Microstructure Analysis

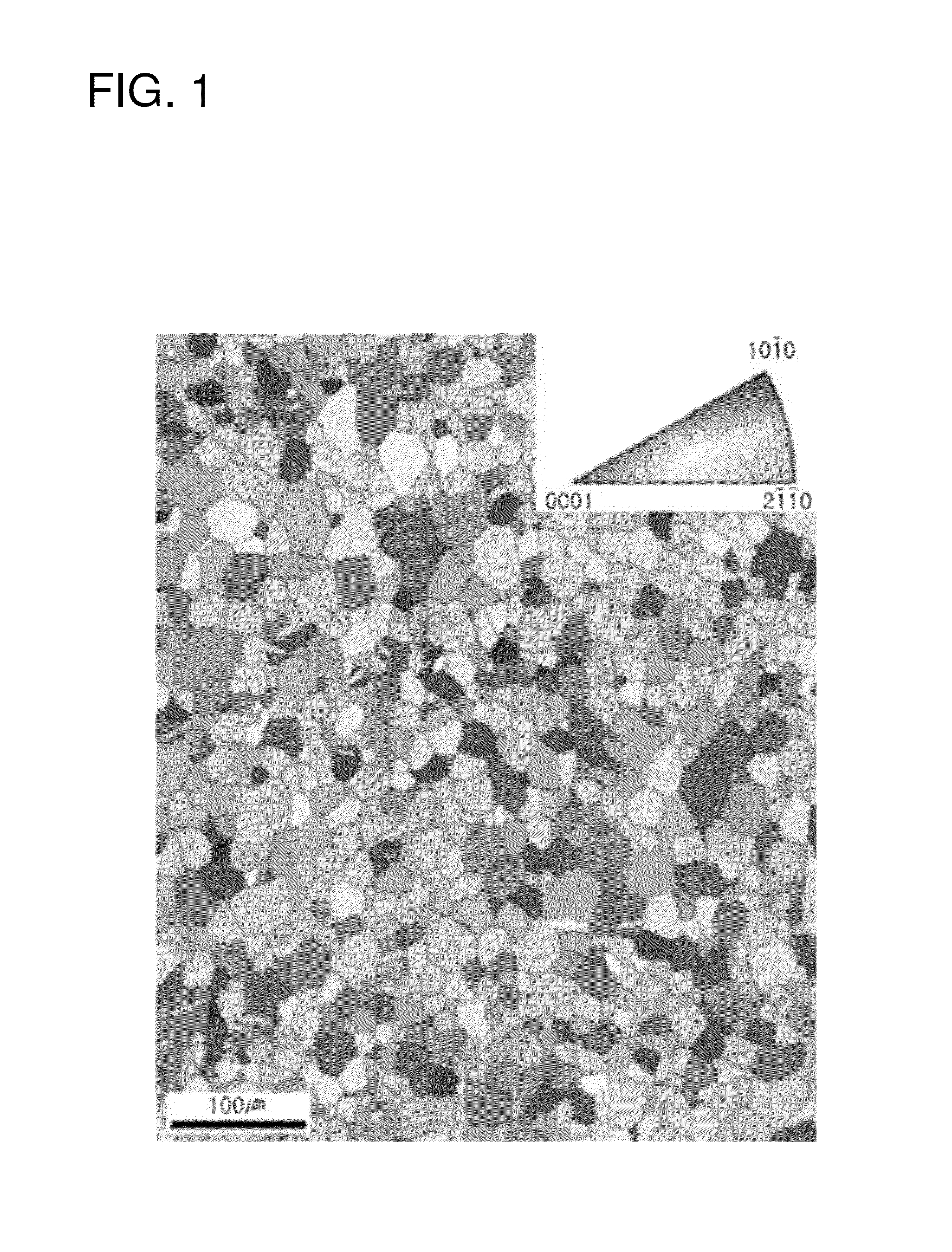

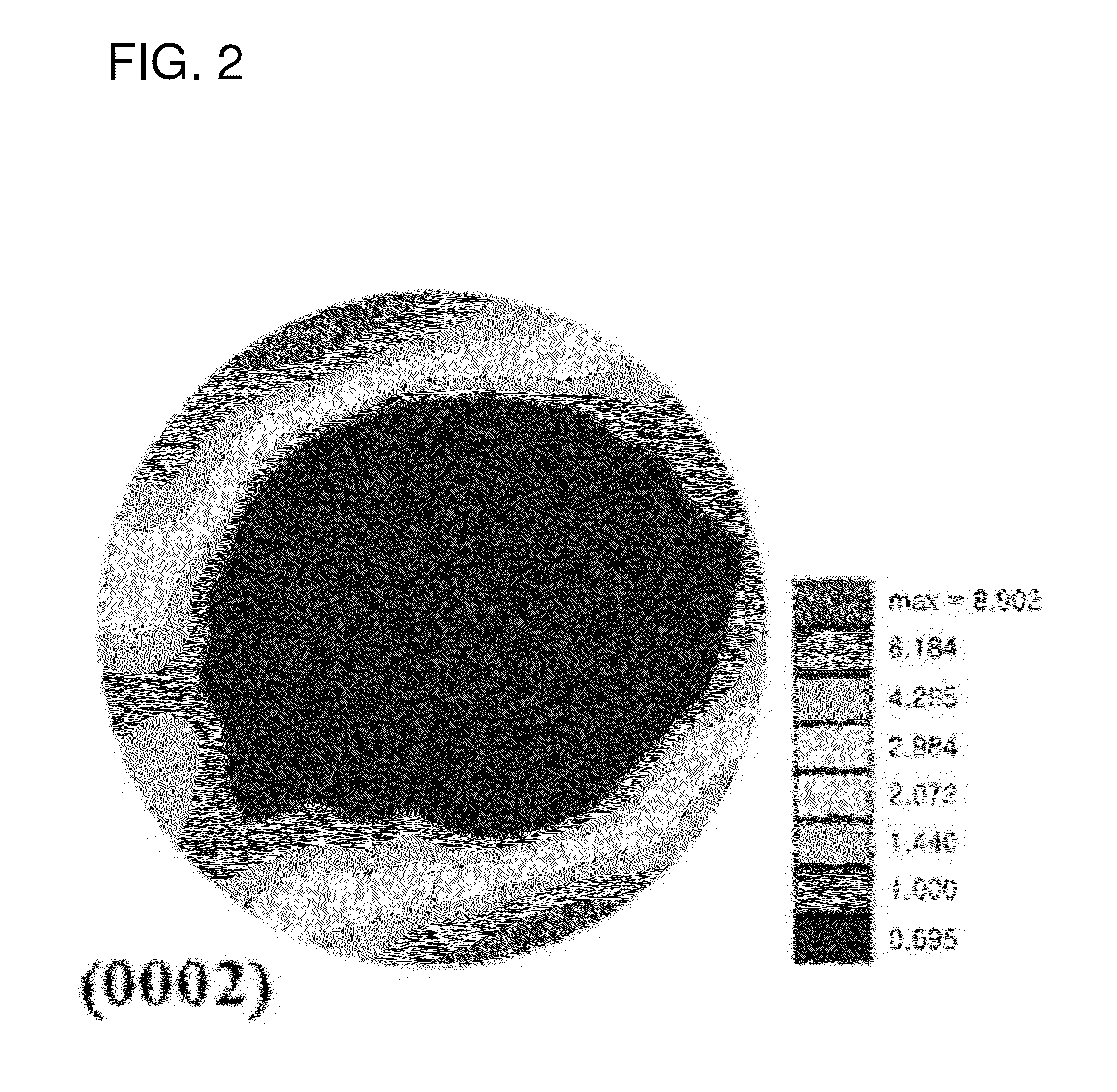

[0093]In order to analyze the microstructure of the magnesium alloy fabricated according to the present invention, electron back scattered diffraction (EBSD) and transmission electron microscope (TEM) were used, and the following results were obtained (see FIGS. 1 to 4).

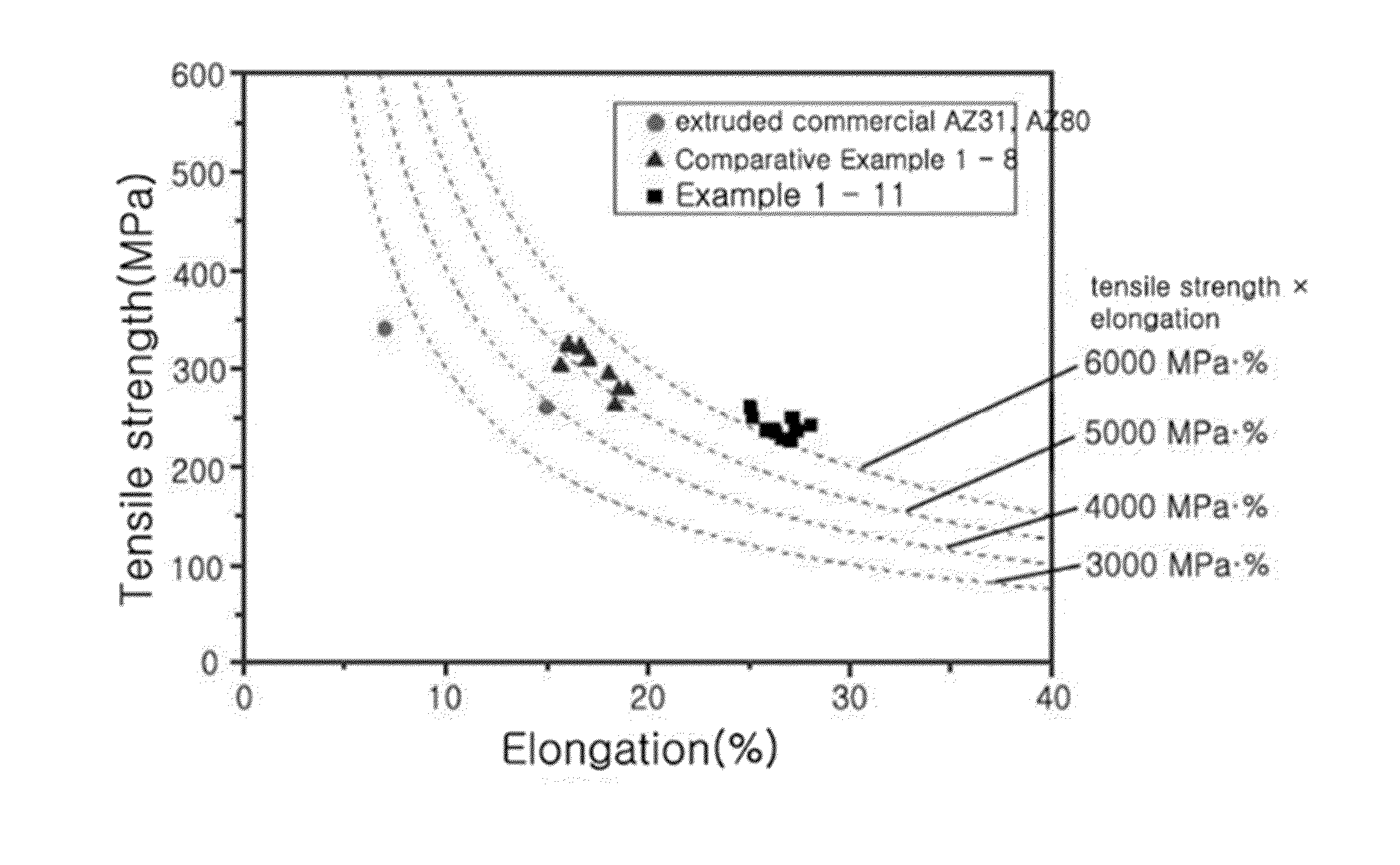

[0094]Referring to FIGS. 1 to 3, the magnesium alloy fabricated according to the present invention shows isotropic microstructure, with its basal plane being in parallel arrangement along the direction of extrusion, and average grain size being 23.7 μm.

[0095]Further, referring to FIG. 4, the extruded magnesium alloy material fabricated according to the present invention has a small amount of fine second-phase (approximately, 50 to 500 nm in size) along the grain boundary and within the grain.

[0096]From the result shown in FIG. 4, it is concluded that the fine second-phases dispersed along the grain boundary and within the grain of the extruded magnesium alloy material are the Mg2Sn phase formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com