Short-process preparing method for high-strength and high-conduction Cu-Cr-Ag alloy

A cu-cr-ag, short-process technology, applied in the field of non-ferrous metal processing, can solve the problems of complex solution treatment operation, control of alloy microstructure and performance stability, and influence on alloy properties, so as to eliminate the need for solution quenching treatment process, Improved softening resistance and controllable degree of recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

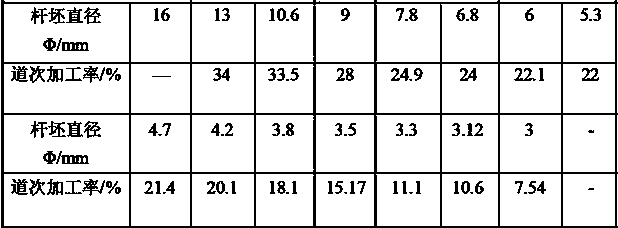

Embodiment 1

[0031] Step 1. According to the alloy composition: 0.3 wt.% Cr, 0.08 wt.% Ag, 0.02 wt.% Mg, and the balance is Cu. Among them, pure silver is selected for silver, pure magnesium is selected for magnesium, Cu-Cr intermediate alloy is selected for chromium, and pure copper is used to fill up the remaining copper. Put the raw materials into the intermediate frequency induction furnace for melting, and use an appropriate amount of dehydrated carbon powder as the covering agent. Specific smelting process: Put pure copper into an intermediate frequency induction furnace for smelting, use dehydrated carbon powder as a covering agent, and the melting temperature is 1200-1250°C, first add pure silver and pure Mg for smelting, its main function is to prevent the Cr element Excessive burning to avoid the difference in Cr element content in different parts of the long-length alloy product, keep it at 1250°C for 10min, then add Cu-Cr master alloy, and keep it at 1200°C for 8min. On-line t...

Embodiment 2

[0039] Step 1. According to the alloy composition: 0.7 wt.% Cr, 0.08 wt.% Ag, 0.02 wt.% Mg, and the balance is Cu. Among them, pure silver is selected for silver, Cu-Cr intermediate alloy is selected for chromium, and the remaining copper is filled with pure copper. The raw materials are put into a medium frequency induction furnace for melting, and an appropriate amount of dehydrated charcoal powder is used as a covering agent, and the melting temperature is 1200-1250°C. Specific smelting process: put pure copper into an intermediate frequency induction furnace for smelting, use dehydrated carbon powder as a covering agent, and the melting temperature is 1200~1250°C, first add pure silver and pure Mg for smelting, keep at 1250°C for 10 minutes, then Add Cu-Cr master alloy and keep it at 1200°C for 8min. On-line testing of ingredients, supplementing raw materials until they meet ingredient requirements.

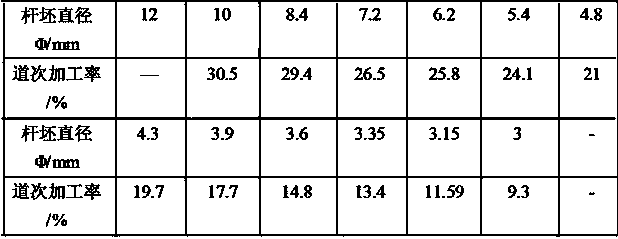

[0040] Step 2: Prepare a Φ14 mm Cu-Cr-Ag alloy billet conforming to th...

Embodiment 3

[0047] Step 1. According to the alloy composition: 0.7 wt.% Cr, 0.08 wt.% Ag, 0.02 wt.% Mg, and the balance is Cu. Among them, pure silver is selected for silver, Cu-Cr intermediate alloy is selected for chromium, and the remaining copper is filled with pure copper. The raw materials are put into a medium frequency induction furnace for melting, and an appropriate amount of dehydrated charcoal powder is used as a covering agent, and the melting temperature is 1200-1250°C. Specific smelting process: put pure copper into an intermediate frequency induction furnace for smelting, use dehydrated carbon powder as a covering agent, and smelt at a temperature of 1200-1250°C. Add Cu-Cr master alloy and keep it at 1200°C for 8min. On-line testing of ingredients, supplementing raw materials until they meet ingredient requirements.

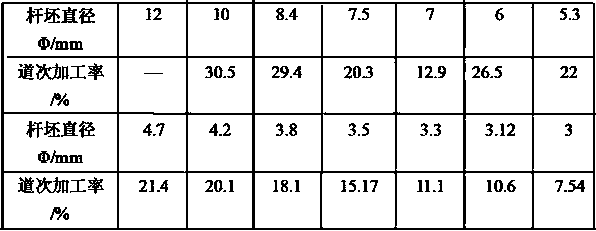

[0048] Step 2: Prepare a Φ14 mm Cu-Cr-Ag alloy billet conforming to the design composition by upward continuous casting, and the upward temperature is 1200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com