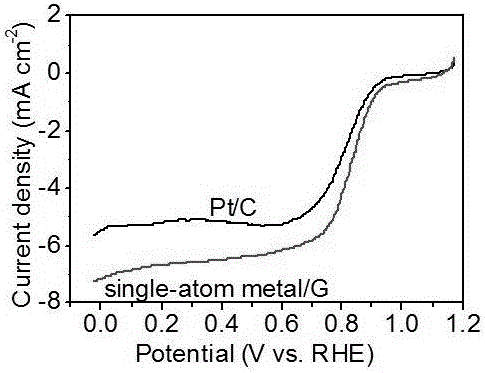

Monodisperse metal atom/graphene composite catalyst and preparation method and application thereof

A graphene composite and metal atom technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Reunion, monatomic higher problems

- Summary

- Abstract

- Description

- Claims

- Application Information

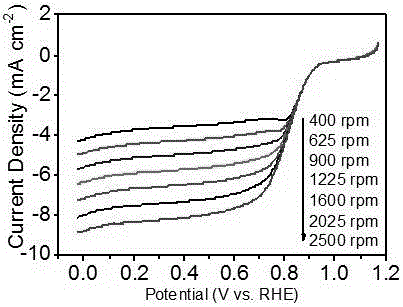

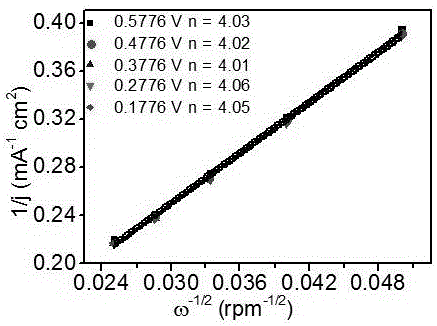

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] (1) Using polytetrafluoroethylene (PTFE) as a binder, the sulfur-doped graphene powder was pressed into a self-supporting columnar electrode as the anode and cathode, and the thickness of the anode and cathode were both 5 mm. The mass ratio of PTFE to sulfur-doped graphene powder was 0.05 g / g. Both the anode and the cathode contain more than 50% graphite by mass, with a resistivity of 0.3 kohm·m (0.3 KΩ·m), pores, and a specific surface area of 4 square meters per gram (4 m 2 / g). The pressure of pressing the electrode is 45 MPa, and the temperature is 80 °C. Two types of electrodes, anode and cathode, form an array. The distance between anode and cathode is 1 mm). The anode and cathode are separated by polyethylene film. The polyethylene bags have an average pore size of 10 µm. (2) Apply a DC voltage of +8 V to -8 V between the anode and the cathode, electrolyze for 60 h, exchange the electrodes every 3 h, and control the electrolysis temperature at 40 °C. The ...

Embodiment 2

[0118] (1) Using polytetrafluoroethylene (PTFE) as a binder, the phosphorus-sulfur-doped graphene powder was pressed into a self-supporting columnar electrode as the anode and cathode, and the thickness of the anode and cathode were both 5 mm. The mass ratio of PTFE to phosphorus-sulfur-doped graphene powder is 0.05 g / g. Both the anode and the cathode contain more than 50% graphite by mass, with a resistivity of 0.3 kohm·m (0.3KΩ·m), pores, and a specific surface area of 4 square meters per gram (4 m 2 / g). The pressure of pressing the electrode is 45 MPa, and the temperature is 80 °C. Two types of electrodes, anode and cathode, form an array. The distance between anode and cathode is 1 mm. The anode and cathode are separated by polypropylene film. The polypropylene bags have an average pore size of 10 µm. (2) Apply a DC voltage of +8 V to -8 V between the anode and the cathode, electrolyze for 60 h, exchange the electrodes every 3 h, and control the electrolysis tempera...

Embodiment 3

[0120] (1) Using polytetrafluoroethylene (PTFE) as a binder, the phosphorus-sulfur-boron-doped graphene powder was pressed into a self-supporting columnar electrode as the anode and cathode, and the thickness of the anode and cathode were both 5 mm. The mass ratio of PTFE to phosphorus-sulfur-boron-doped graphene powder is 0.05 g / g. Both the anode and the cathode contain more than 50% graphite by mass, with a resistivity of 0.3 kohm•m (0.3 KΩ•m), pores, and a specific surface area of 4 square meters per gram (4 m2 / g). The pressure of pressing the electrode is 45 MPa, and the temperature is 80 °C. Two types of electrodes, anode and cathode, form an array. The distance between anode and cathode is 1 mm. The anode and cathode are separated by polyethylene film. The polyethylene bags have an average pore size of 10 µm. (2) Apply an AC voltage of 10 V between the anode and the cathode, electrolyze for 30 h, and change the direction of the current every 30 min. The electrolys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com