Graphene/metal oxide composite cathode material for lithium ion battery and preparation

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., to achieve good electrochemical performance, strong binding ability, and superior rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

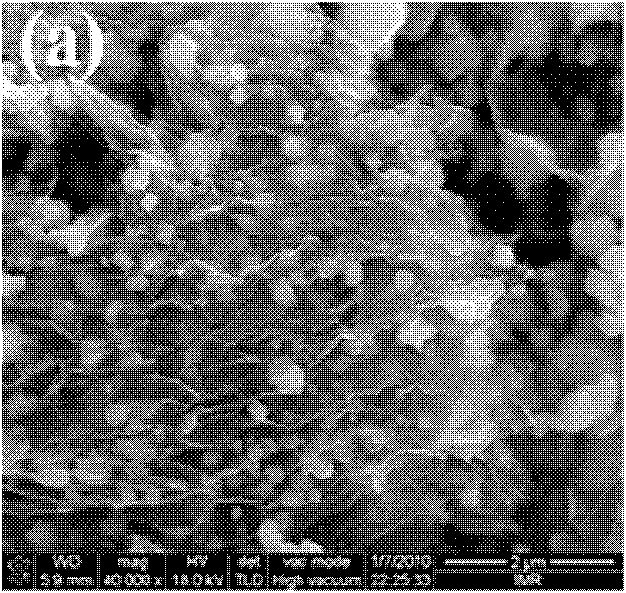

[0040] Example 1: Preparation of graphene / iron tetroxide composite negative electrode material by liquid phase in situ polymerization method combined with in situ solid phase dehydration carbon thermal reduction reaction

[0041] (1) Weigh 50mg of graphene, add it to 150ml of 0.05M ferric chloride aqueous solution for ultrasonic dispersion to make a graphene dispersion, heat and stir the graphene dispersion at 80°C for hydrolysis, and the hydrolysis time is 4-12h (the present embodiment is 8h), make graphene / iron oxyhydroxide complex, the length of gained hydrolysis complex is 200-400nm, and width is 60-80nm;

[0042] (2) In-situ solid-phase dehydration charcothermal reduction reaction: After the hydrolyzed compound in step (1) is filtered and dried, the graphene and The in-situ dehydration and charcothermal reduction reaction of iron oxyhydroxide takes 4 to 8 hours (6 hours in this embodiment) to obtain the graphene / ferric iron tetroxide composite negative electrode material....

Embodiment 2

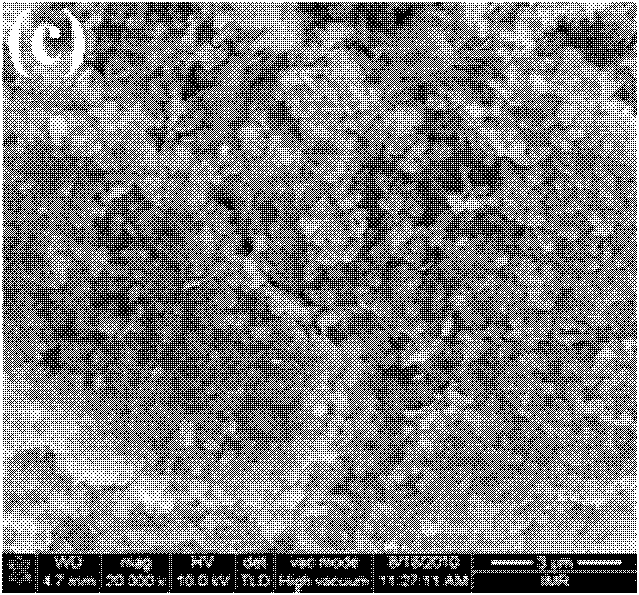

[0043] Example 2: Preparation of graphene / cobalt tetroxide composite negative electrode material by co-precipitation method combined with in-situ heat treatment oxidation

[0044] (1) Weigh the graphene of 100mg, join in the isopropanol and water mixed solution of 100ml (volume ratio 1: 1) carry out ultrasonic dispersion 0.5h and make graphene dispersion liquid, transfer dispersion liquid in the there-necked flask afterwards and Pass through argon protection, weigh 0.05-0.5mol (0.1mol in this embodiment) cobalt nitrate and join in the above-mentioned dispersion liquid, then drip into the ammonia solution (concentration 25wt%) of stoichiometric ratio, fully under the protection of argon atmosphere Stir for 3 hours to ensure that the reaction is complete, then filter and dry to obtain the graphene / cobalt hydroxide composite;

[0045] (2) In-situ heat treatment oxidation reaction: the co-precipitated composite in step (1) is subjected to an in-situ dehydration oxidation reaction ...

Embodiment 3

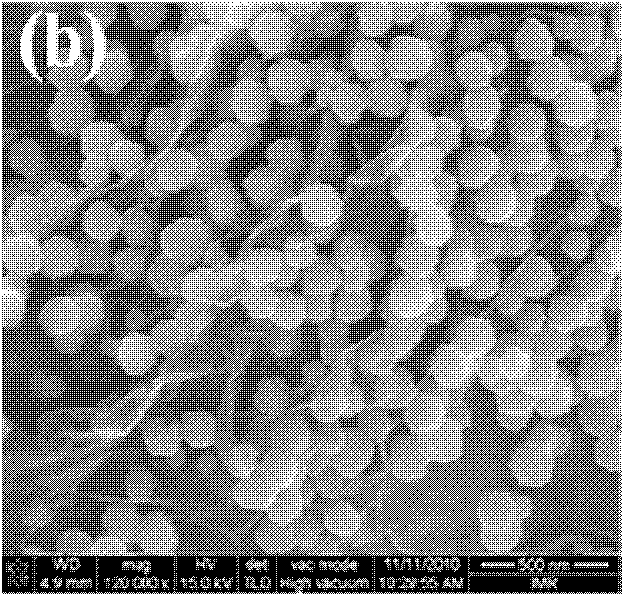

[0046] Embodiment 3: Synthesis of graphene / ferric oxide composite negative electrode material by hydrothermal method

[0047] (1) Weigh the graphene of 50mg, join in the 0.06M ferric nitrate aqueous solution of 50ml and carry out ultrasonic dispersion and make graphene dispersion liquid, then add 7.5mmol urea and 4mmol sodium citrate in above-mentioned graphene dispersion liquid and stir 2 -4h (the present embodiment is 4h), then put into the reaction pot and carry out hydrothermal reaction, the reaction temperature is 160-200°C (the present embodiment is 180°C), and the reaction time is 6-24h (the present embodiment is 12h) , to obtain a graphene / ferric oxide composite, in which the ferric oxide is a uniform spherical particle, and all of them are ferric oxide nanospheres with a size of 80-100nm formed by agglomeration of nanoparticles. The scanning electron microscope image is shown in Figure 1(b). It can be seen that the ferric oxide nanospheres are evenly distributed in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com