Light-emitting diode driving apparatus including charging/discharging capacitor

A technology of light-emitting diodes and driving devices, which is applied in the direction of electroluminescent light source, electric lamp circuit layout, electric light source, etc., can solve the problems of power factor deterioration, power supply efficiency deterioration, constant current circuit loss increase, etc., to achieve uniformity , Improve the effect of crest factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

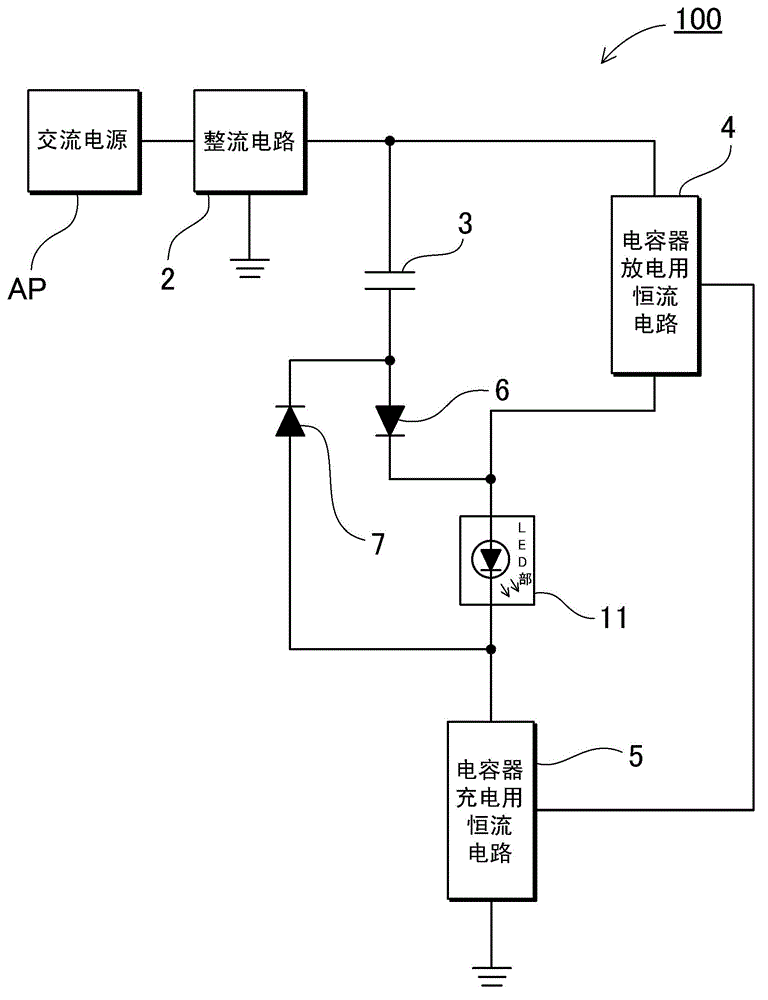

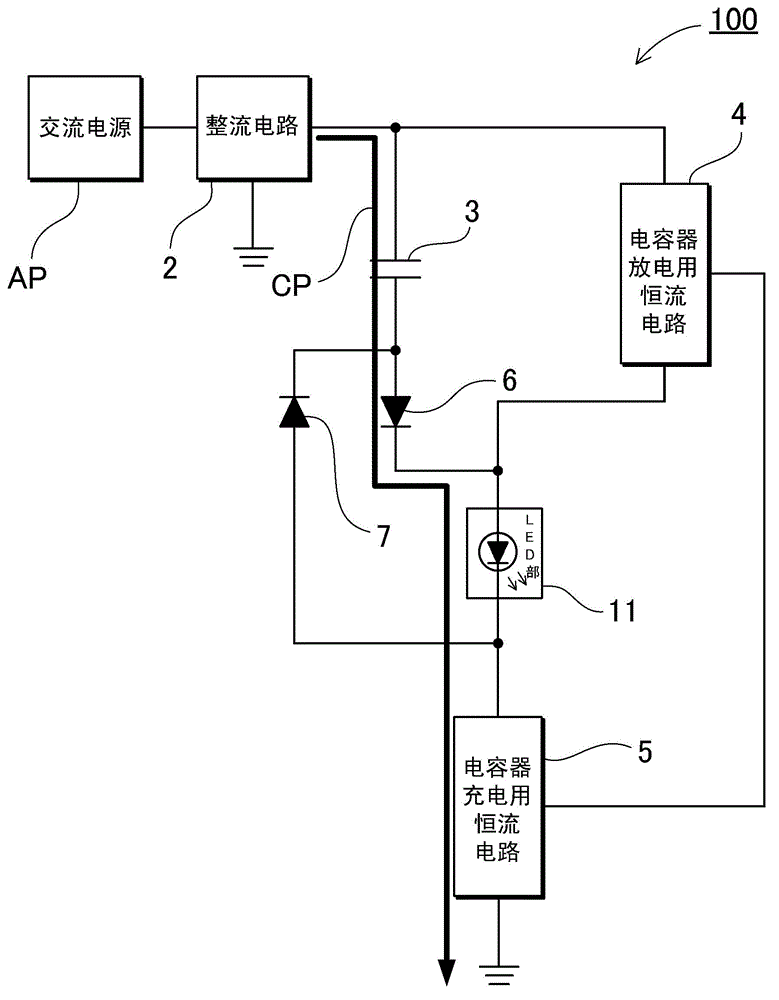

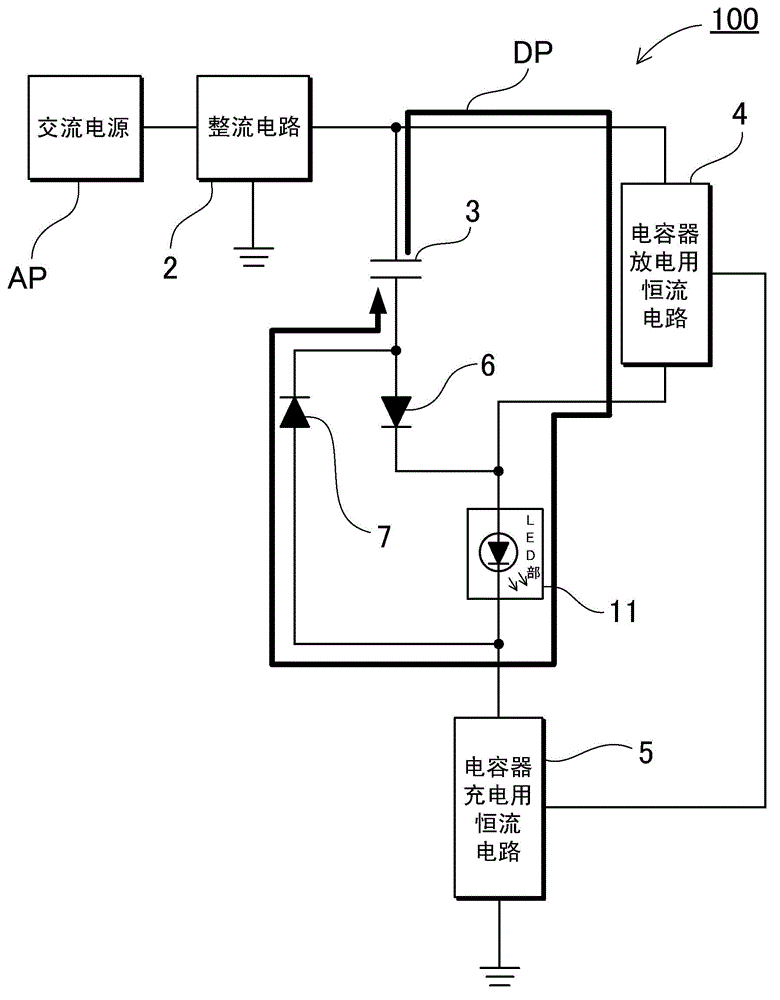

[0040] figure 1 A block diagram of the light emitting diode driving device 100 according to Embodiment 1 of the present invention is shown. This light emitting diode driving device 100 includes a rectifier circuit 2 , a first LED unit 11 , a capacitor charging constant current circuit 5 , a capacitor discharging constant current circuit 4 , a charging diode 6 , a discharging diode 7 , and a charging and discharging capacitor 3 . This light emitting diode driving device 100 is connected to an AC power supply AP, and obtains a rectified voltage (pulsating current voltage) obtained by rectifying the AC voltage in the rectifying circuit 2 . In addition, between the AC power supply AP and the rectifier circuit 2, a fuse 81 for preventing overcurrent or a surge protection circuit for preventing overvoltage can also be provided.

[0041] The LED section is a block in which one or more LED elements are connected in series and / or in parallel. As the LED element, a surface mount type...

Embodiment approach 2

[0052] Specifically, in figure 1 In the example of , an example using one LED unit was described, but a plurality of LED units may also be used. It is also possible to connect a plurality of LED units in series, and to add an LED unit to the charge path CP, to add an LED unit to the discharge path DP, or to add an LED unit to each of the charge path CP and the discharge path DP. Here, as Embodiment 2, in Figure 6 A circuit example in which the second LED unit 12 is added to the charge path CP and the third LED unit 13 is added to the discharge path DP is shown in FIG. In this way, it is possible to change the combination of the LED units that are lit (the number of LED units that emit light) during each of the capacitor charging period, the capacitor discharging period, and the transition period between the two periods. Thus, the power efficiency can be further improved and the LED voltage V f freedom of setting.

[0053] As above, according to V c+ =V che -V f and V ...

Embodiment 1

[0058] Next, at Figure 13 The light-emitting diode driving device 100' shows the composition of figure 1 A specific example of the circuit of the light emitting diode driving device 100 according to Embodiment 1 is described in Figure 14 The light emitting diode driving device 200' shows the same structure Figure 6 A specific example of the circuit of the light emitting diode driving device 200 according to the second embodiment. In each circuit example 100', 200', the basic operation has been described as above. Here, the operation of the light emitting diode driving device 200' according to the second embodiment will be mainly described. In addition, the operation of the light-emitting diode driving device 100' of the first embodiment is substantially the same as that of the light-emitting diode driving device 200' of the second embodiment, because the first LED part 11, the second LED part 12, and the third LED part 13 can be In other words the first LED section 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com