Welding device and welding method for high temperature superconducting strip

A high-temperature superconducting strip material and welding device technology, which is applied in the direction of electric heating devices, auxiliary devices, welding equipment, etc., can solve the problems that the solder cannot be heated and melted evenly, affects the welding speed, and the pressure cannot be controlled, so as to achieve the rapidity of colleges and universities. The effect of reducing joint resistance and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

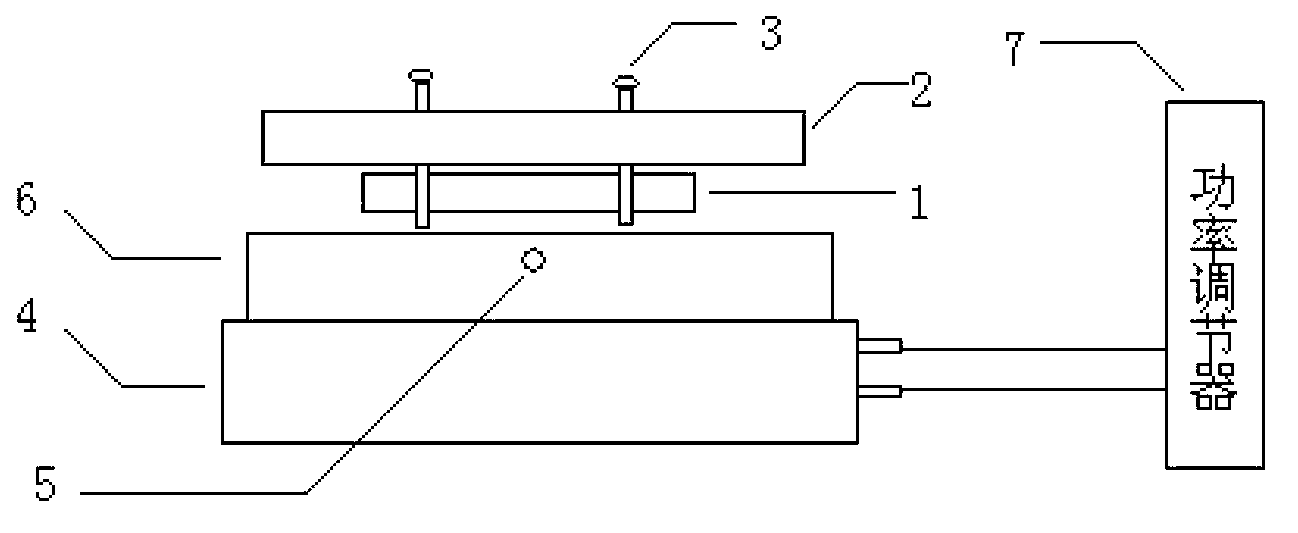

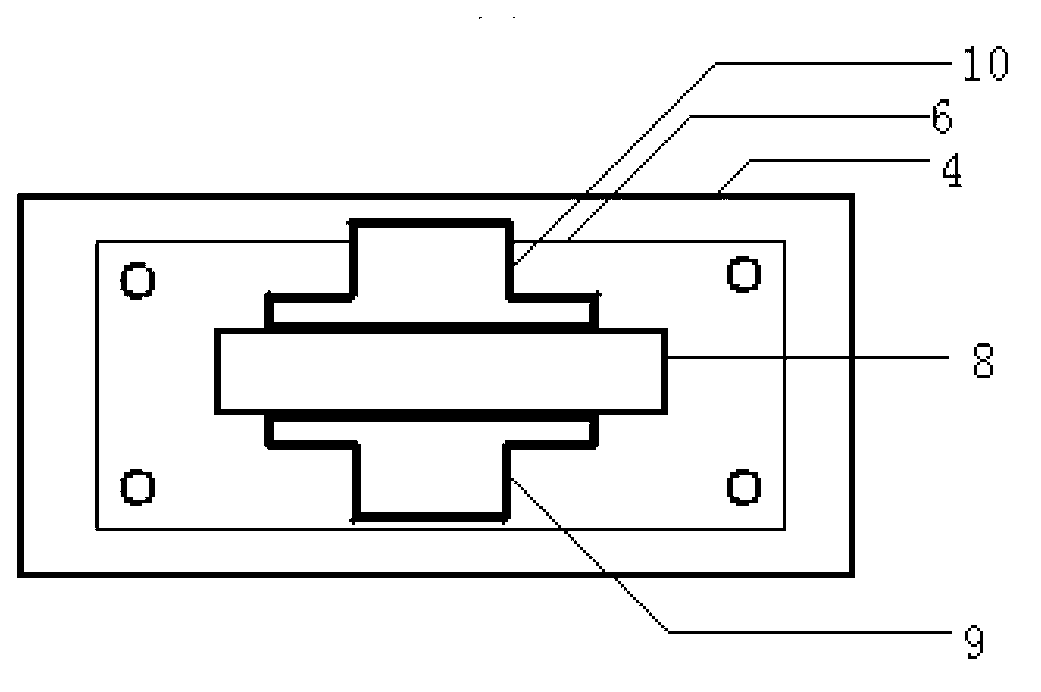

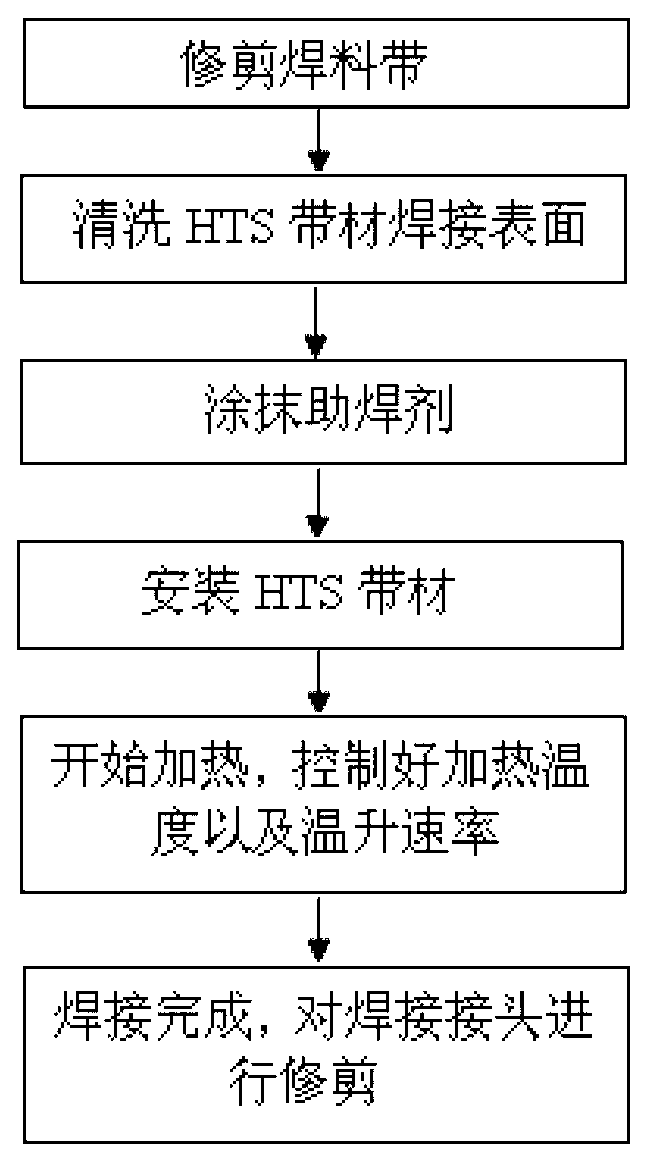

[0027] Such as figure 1 and figure 2 , the welding device used for high-temperature superconducting strips includes a heating plate 4, a heat conduction uniform temperature welding base 6, etc., and the heat conduction uniform temperature welding base 6 is fixed on the heating plate 4, and the heating plate 4 is externally connected with a power regulator 7. There is a thermometer mounting hole 5 on the side of the heat conduction and uniform temperature welding base 6. The middle area of the upper plane of the heat conduction and uniform temperature welding base 6 has a welding area 8 for placing high-temperature superconducting strips. The two sides of the welding area 8 are respectively There are correction splints 9 and 10, and there is a silicone rubber pressing plate 1 and a welding compression plate 2 directly above the heat-conducting and uniform-temperature welding base 6, and the welding compression plate 2 is connected to the heat-conducting and uniform-temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com