System for calibrating particulate matter measuring instruments and calibrating method of system

A technology for calibrating systems and measuring instruments, used in measuring devices, particle suspension analysis, scientific instruments, etc., to achieve the effects of accurate value, increased effective control, and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

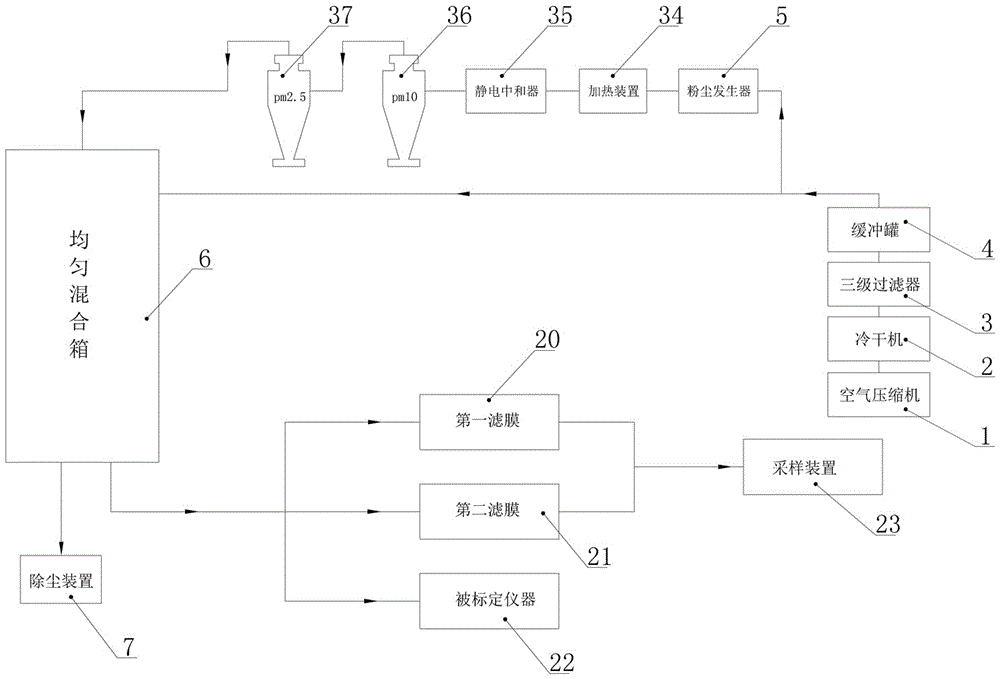

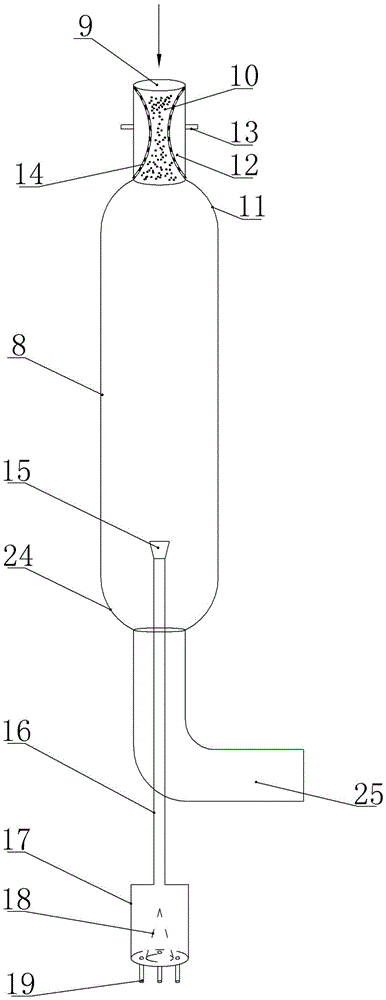

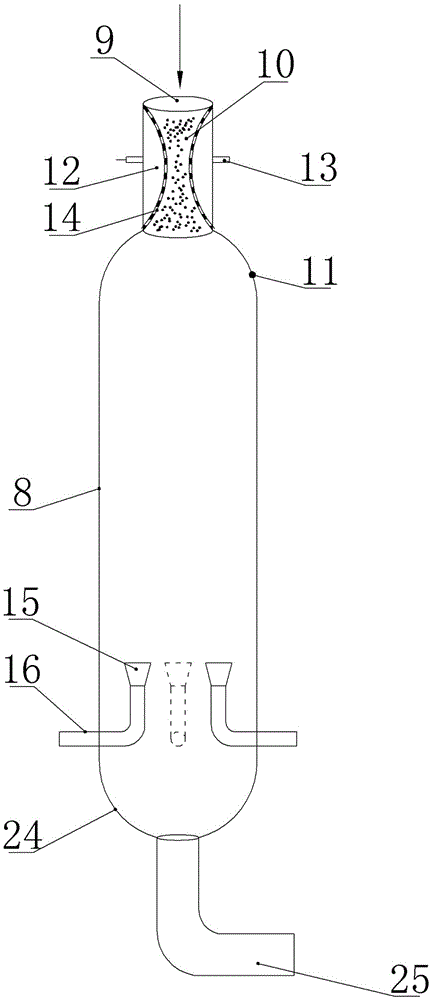

[0026] Embodiment one: see figure 1 , figure 2 , Figure 4 — Figure 7 , a particle measuring instrument calibration system, including sequentially connected compressed air processing device, dust generator 5, heating device 34, electrostatic neutralizer 35, PM10 standard cutting head 36, PM2.5 standard cutting head 37 and uniform mixing box 6. The compressed air treatment device includes an air compressor 1, a cold dryer 2, a three-stage filter 3 and a buffer tank 4, and the lower part of the uniform mixing box 6 is connected with a dust sample collector and a dust removal device 7; Said homogeneous mixing box 6 comprises a cylindrical sedimentation mixing chamber 8, a mixing section arranged on the upper part of the sedimentation mixing chamber 8 and a sampling vent section arranged at the lower part of the sedimentation mixing chamber, and said mixing section comprises a cylindrical dust feed pipe 9. A mixer 10 with a single leaf hyperboloid structure arranged in the du...

Embodiment 2

[0030] Embodiment two: see figure 1 , image 3 — Figure 7 , the structure of the present embodiment is basically the same as that of Embodiment 1, and the same parts will not be repeated. The difference is that the dust sample collector includes three constant-velocity dust collectors that are circumferentially distributed around the axis of the settling mixing chamber 8. The sampling head 15 is connected to the sampling tube 16 arranged at the bottom of the three isokinetic sampling heads 15, and the three sampling tubes 16 are respectively connected to the first filter membrane 20, the second filter membrane 21 and the calibrated instrument 22, the first filter membrane 20 and the The second filter membrane 21 is connected with a sampling device 23 at the same time.

Embodiment 3

[0031] Embodiment three: see figure 1 — Figure 7 , a calibration method using the particulate matter measuring instrument calibration system described in Embodiment 1 or Embodiment 2. After the clean compressed air is passed into the dust generator, the dust samples generated by the dust generator are treated to prevent static electricity, and then enter the The standard cutting head and the uniform mixing box are uniformly mixed with compressed air in the uniform mixing box, and the dust samples collected by the constant velocity sampling head enter the first filter membrane, the second filter membrane sampler and the calibrated instrument respectively; the sampling device Adjust the flow rate to be the same as the flow rate of the calibrated instrument, and read the reading of the calibrated instrument at the same acquisition time; at the same time, use a high-precision balance to weigh the two filter membranes; calculate the weight of the two filter membranes The ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com