Prep. of alumina---monox composite oxides film

A composite oxide and thin film preparation technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of difficult to obtain aluminum oxide-silicon oxide composite oxide thin film with adjustable ratio, co-deposition process Difficulty in controlling etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

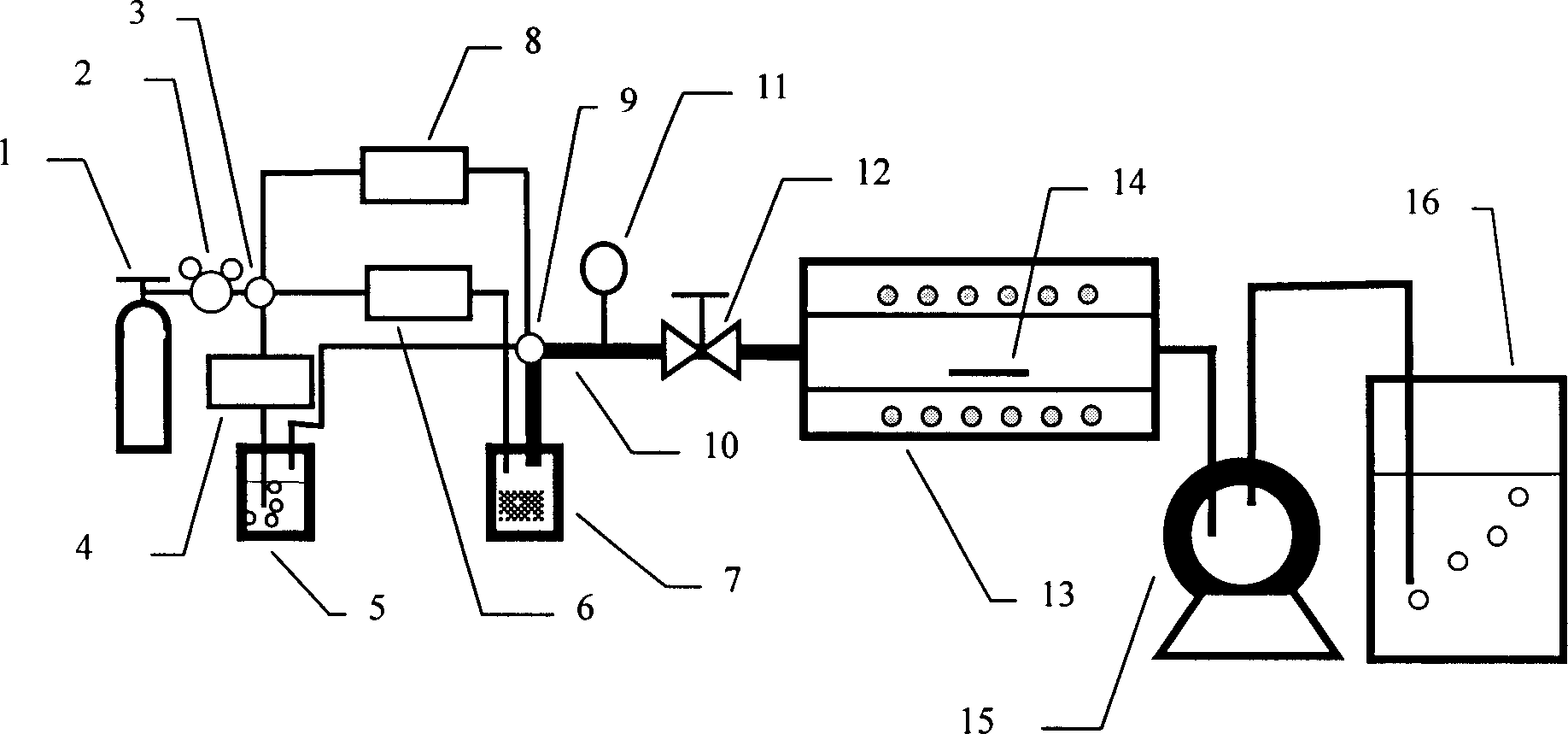

[0014] figure 1 Schematic diagram of the equipment for the preparation of alumina-silicon oxide composite oxide films for CVD.

[0015] First start the vacuum pump 15 to reduce the pressure in the furnace to below 76 Torr, and the vacuum pump continues to work. The deposition furnace 13 is then raised to a constant temperature. Unscrew the valve 1 on the top of the Ar gas cylinder to release the Ar, the Ar flows through the pressure reducer 2 and then depressurizes to 0.4-0.6MPa, the low-pressure Ar passes through the four-way pipe 3 and is divided into three parts, and a part of Ar passes through the flow meter 4 and enters TEOS for bubbling In bottle 5, the flow rate is 200-400ml / min, the bubble bottle is a glass flask, and the TEOS liquid is contained inside, and the water bath for the bubble bottle is kept at a constant temperature of 40-60°C. Part of Ar enters AlCl through flowmeter 6 3 In the evaporator 7, the flow rate is 200-40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com