Hydrogen peroxide bleaching stabilizer for cotton fabrics

An oxygen bleaching stabilizer, cotton fabric technology, applied in textiles, papermaking, dyeing and other directions, can solve problems such as environmental pollution, easy formation of silica scale, etc., to avoid holes, effectively decompose, and reduce catalytic effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

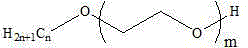

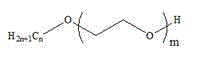

[0018] An oxygen bleaching stabilizer for cotton fabrics consists of the following mass percentages: sodium ethylenediamine di-orthophenylacetate 10%, polyacrylamide 0.2%, ethylenediamine 8%, boric acid 5%, sodium citrate 5% , anhydrous magnesium sulfate 2%, horse-propylene copolymer 5%, fatty alcohol polyoxyethylene ether 8%, distilled water 56.8%.

Embodiment 2

[0020] An oxygen bleaching stabilizer for cotton fabrics consists of the following mass percentages: sodium ethylenediamine di-orthophenylacetate 10%, polyacrylamide 0.2%, ethylenediamine 8%, boric acid 5%, sodium citrate 5% , magnesium chloride hexahydrate 4%, horse-propylene copolymer 5%, fatty alcohol polyoxyethylene ether 8%, distilled water 44.8%.

Embodiment 3

[0022] An oxygen bleaching stabilizer for cotton fabrics consists of the following mass percentages, sodium ethylenediamine di-orthophenylacetate 15%, polyacrylamide 0.3%, diglycolamine 5%, boric acid 5%, sodium citrate 5% %, anhydrous magnesium sulfate 2%, horse-propylene copolymer 6%, fatty alcohol polyoxyethylene ether 8%, and distilled water 53.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com