Self-vulcanization oil-soluble molybdenum based bimetallic catalyst and preparation method and applications thereof

A bimetallic catalyst and vulcanized oil technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and hydrocarbon oil treatment, can solve the problems of reduced catalytic hydrogenation activity, large sulfide particle size, and difficult vulcanization, etc., to achieve Effects of suppressing coke formation, simple process, and excellent hydrogenation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

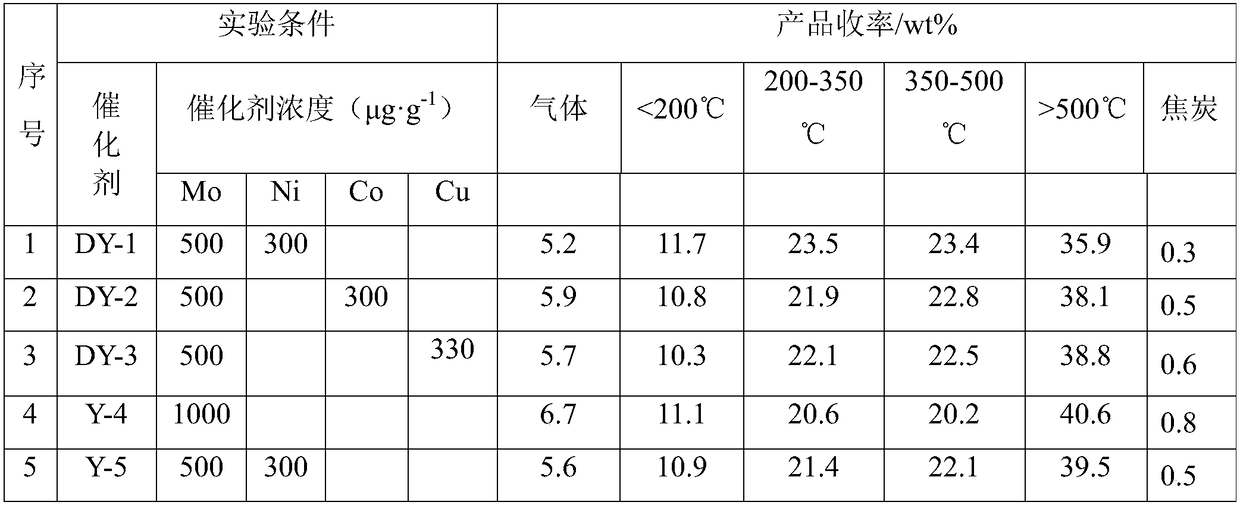

Embodiment 1

[0020] Weigh 30g of ammonium heptamolybdate, add 100mL of distilled water, and then add 30mL of concentrated ammonia water to obtain solution A. Weigh 49.3g of nickel nitrate hexahydrate, add ammonia water, ammonia water / nickel molar ratio=10 / 1, and obtain solution B. Under the condition of stirring, solution B was added into solution A, the reaction temperature was 60° C., and the reaction time was 4 hours, and a green precipitate was formed. The precipitate was filtered, washed with water, and dried at room temperature to obtain ammonium nickel molybdate. Then, nickel ammonium molybdate was added to the ammonium sulfide solution with a sulfur content of 8%, the sulfur content of the vulcanizing agent / molybdenum molar ratio=6 / 1, the temperature was raised to 80° C., and the reaction was stirred for 4 hours. The liquid containing the precipitate was suction-filtered with a Buchner funnel, washed with distilled water, and left to dry at room temperature for 12 hours to obtain ...

Embodiment 2

[0024] Weigh 30g of ammonium heptamolybdate, add 100mL of distilled water, and then add 30mL of concentrated ammonia water to obtain solution A. Weigh 49.4g of cobalt nitrate hexahydrate, add ammonia water, ammonia water / cobalt molar ratio=10 / 1, and obtain solution B. Under the condition of stirring, solution B was added into solution A, the reaction temperature was 60° C., and the reaction time was 4 hours, and a precipitate was formed. The precipitate was filtered, washed with water, and dried at room temperature to obtain ammonium cobalt molybdate. Then add cobalt ammonium molybdate to the ammonium sulfide solution with a sulfur content of 8%, the sulfur content of the vulcanizing agent / molybdenum molar ratio=6 / 1, heat up to 80°C, and stir for 4 hours. The liquid containing the precipitate was suction-filtered with a Buchner funnel, washed with distilled water, and dried at room temperature for 12 hours to obtain cobalt ammonium tetrathiomolybdate, cobalt / molybdenum molar ...

Embodiment 3

[0028] Weigh 30g of ammonium heptamolybdate, add 100mL of distilled water, and then add 30mL of concentrated ammonia water to obtain solution A. Weigh 41g of copper nitrate trihydrate, add ammonia water, ammonia water / copper molar ratio=10 / 1, and obtain solution B. Under the condition of stirring, solution B was added into solution A, the reaction temperature was 60° C., and the reaction time was 4 hours, and a precipitate was formed. The precipitate was filtered, washed with water, and dried at room temperature to obtain copper ammonium molybdate. Then copper ammonium molybdate is added to the ammonium sulfide solution with a sulfur content of 8%, the sulfur content of the vulcanizing agent / molybdenum molar ratio=6 / 1, the temperature is raised to 80° C., and the reaction is stirred for 4 hours. The liquid containing the precipitate was suction-filtered with a Buchner funnel, washed with distilled water, and left to dry at room temperature for 12 hours to obtain ammonium copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com