One-bath processing method for pure-cotton knitted fabric scouring and bleaching and pigment dyeing

A paint dyeing and processing method technology, applied in the field of textile printing and dyeing, can solve the problems of low production efficiency, water consumption, energy consumption, etc., and achieve the effects of good dispersion protection, strong compatibility, and excellent dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

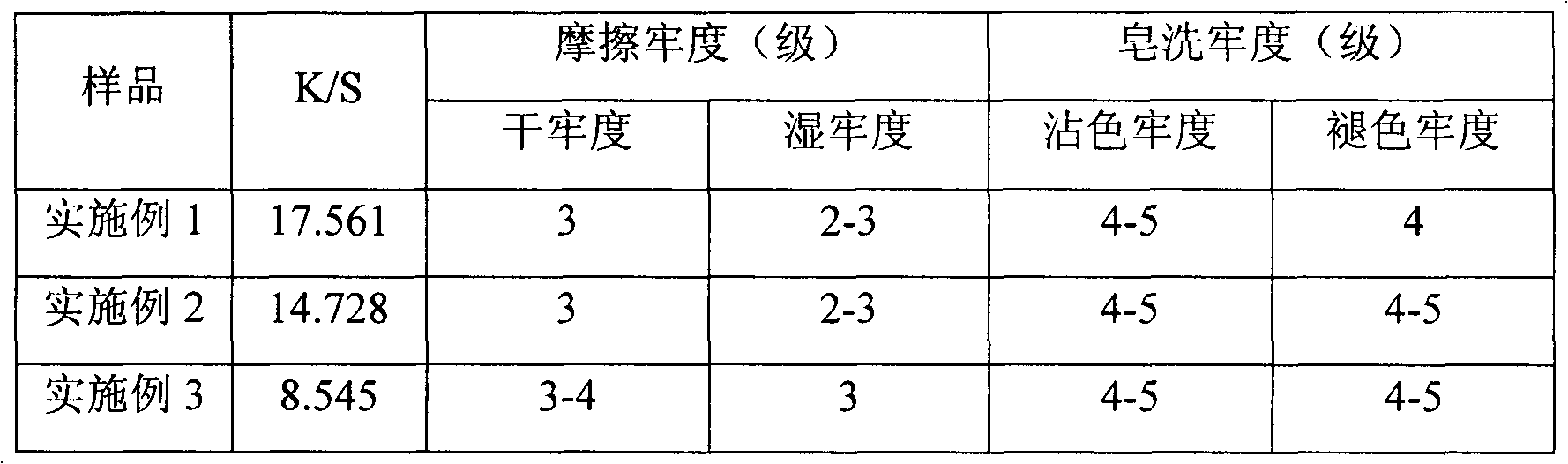

Embodiment 1

[0014] The following processes are used to treat pure cotton knitted fabrics:

[0015] (1) Pure cotton knitted fabrics are subjected to scouring and bleaching treatment. The treatment conditions are: hydrogen peroxide 6ml / L, hydrogen peroxide stabilizer 2g / L, non-ionic surfactant 5g / L, pH11.0, temperature 95°C, time 50min, liquor ratio 1:15;

[0016] (2) After the scouring and bleaching treatment is completed, the temperature of the treatment solution is lowered to 40°C, the pH of the solution is adjusted to 6.8, and 3 g / L of catalase is added for 20 minutes to fully decompose the residual hydrogen peroxide;

[0017] (3) Use the above residual liquid to prepare paint dyeing solution and dye it, the conditions are: cationic paint red 15% owf, temperature 40 ° C, time 80 min; after dyeing is completed, fix the color in the residual liquid, the fixing condition is: cationic adhesive The mixture is 50g / L, the temperature is 80°C, and the time is 30min. After the completion, the f...

Embodiment 2

[0020] The following processes are used to treat pure cotton knitted fabrics:

[0021] (1) Pure cotton knitted fabrics are subjected to scouring and bleaching treatment. The treatment conditions are: hydrogen peroxide 8ml / L, hydrogen peroxide stabilizer 3g / L, non-ionic surfactant 5g / L, pH11.0, temperature 95°C, time 60min, liquor ratio 1:15;

[0022] (2) After the scouring and bleaching treatment is completed, the temperature of the treatment solution is lowered to 40°C, the pH of the solution is adjusted to 7.0, and 5 g / L of catalase is added for 20 minutes to fully decompose the residual hydrogen peroxide;

[0023] (3) Use the above residual liquid to prepare paint dyeing solution and dye it, the conditions are: cationic paint blue 10% owf, temperature 40 ° C, time 70 min; after dyeing is completed, fix the color in the residual liquid, the fixing condition is: cationic adhesive The mixture is 40g / L, the temperature is 80°C, and the time is 30min. After the completion, the ...

Embodiment 3

[0026] The following processes are used to treat pure cotton knitted fabrics:

[0027] (1) Pure cotton knitted fabrics are subjected to scouring and bleaching treatment. The treatment conditions are: hydrogen peroxide 10ml / L, hydrogen peroxide stabilizer 4g / L, non-ionic surfactant 3g / L, pH11.2, temperature 95°C, time 60min, liquor ratio 1:15;

[0028] (2) After the scouring and bleaching treatment is completed, the temperature of the treatment solution is lowered to 40°C, the pH of the solution is adjusted to 7.0, and 5 g / L of catalase is added for 20 minutes to fully decompose the residual hydrogen peroxide;

[0029] (3) Use the above residual liquid to prepare paint dyeing solution and dye it, the conditions are: cationic paint yellow 5% owf, temperature 45 ° C, time 60 min; after dyeing is completed, fix the color in the residual liquid, the fixing condition is: cationic adhesive The mixture is 20g / L, the temperature is 80°C, and the time is 30min. After the completion, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com