Stabilized electrochemical cell active material

A lithium manganese oxide, spinel technology, used in the field of batteries and battery packs with lithium-based active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

100.00

100.00

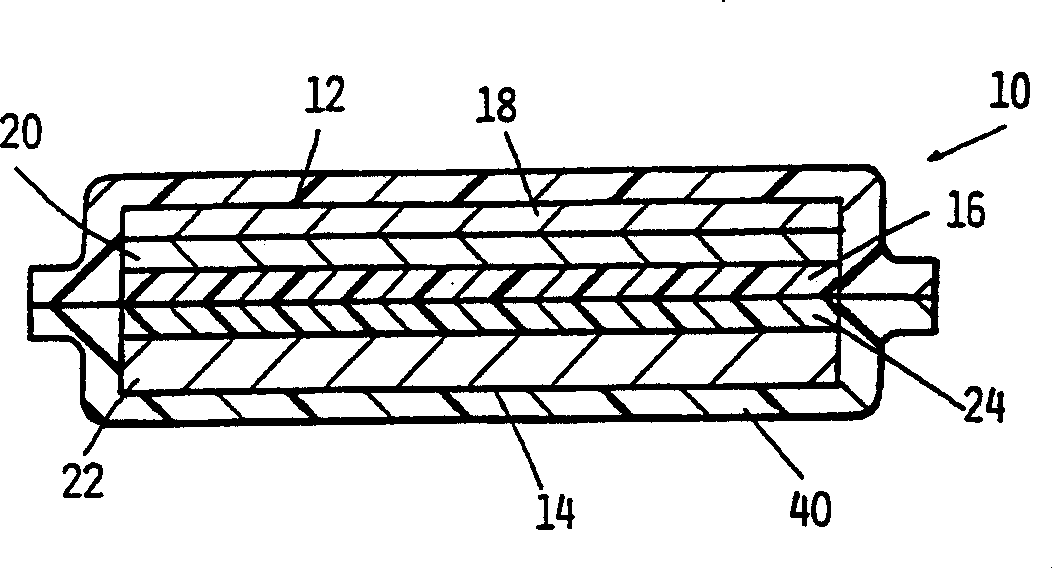

[0052] Put two pieces of 48 cm 2 The electrode material is hot-pressed onto a metal mesh plate to form an electrochemical cell with negative electrode, separator and positive electrode film. Lamination was performed at 120°C and 50 psi. Copper grids are used for the negative electrode laminate and aluminum grids are used for the positive electrode. After initial lamination, the two electrodes and separator were laminated together by hot pressing at 115°C and 40 psi.

[0053] After lamination, three washes (20 minutes each) in a methanol bath extract the plasticizer and create porosity in the battery. After extraction, the cells were vacuum dried overnight at 40°C.

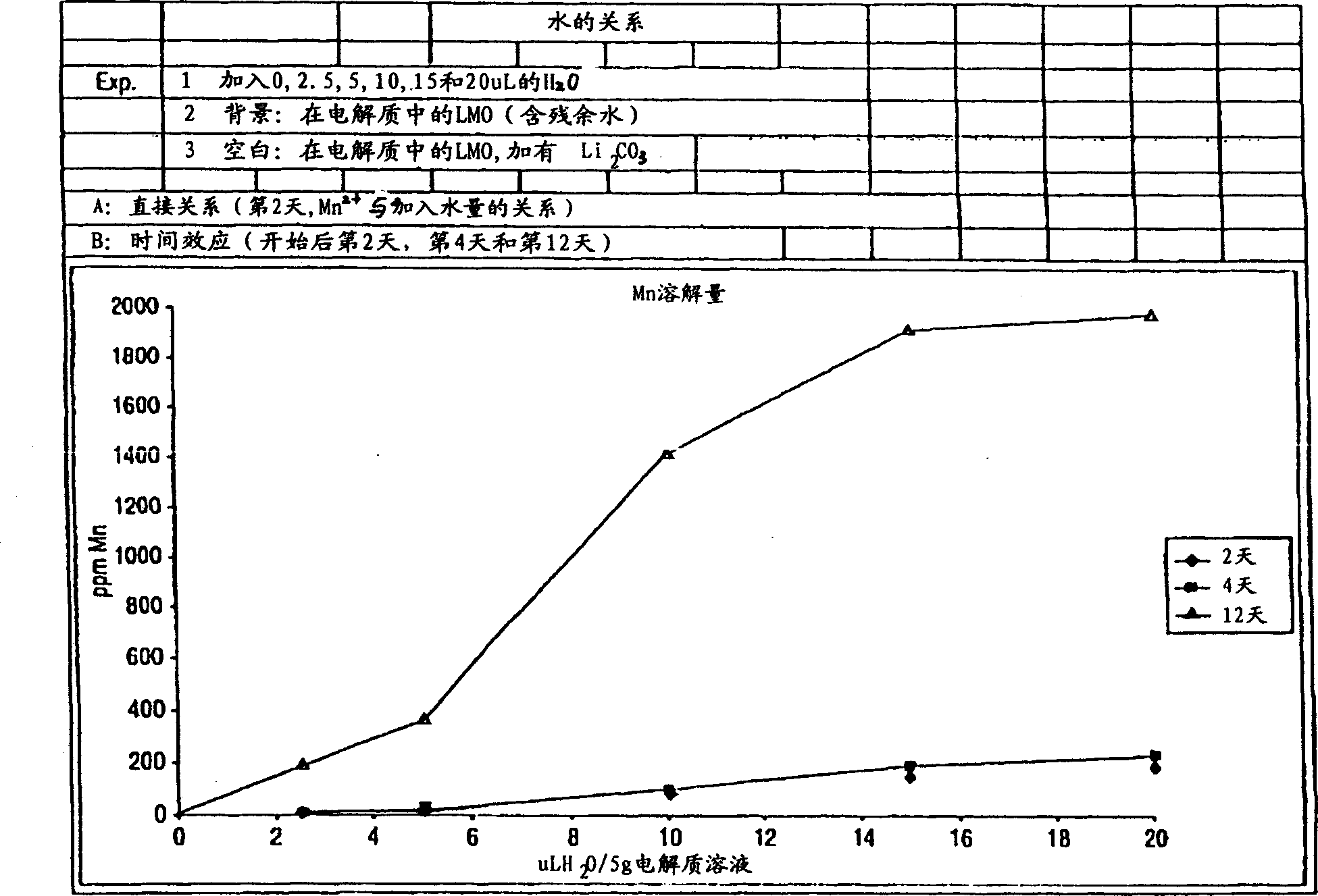

[0054] The electrolyte used for the battery is 2:1 ethylene carbonate and dimethyl carbonate (EC / DMC) with 1 molar concentration of LiPF as the conductive salt 6 (Grant-Ferro Corp., Zachary LA). A basic compound may also be added to the electrolyte solution. Therefore, a b...

Embodiment II

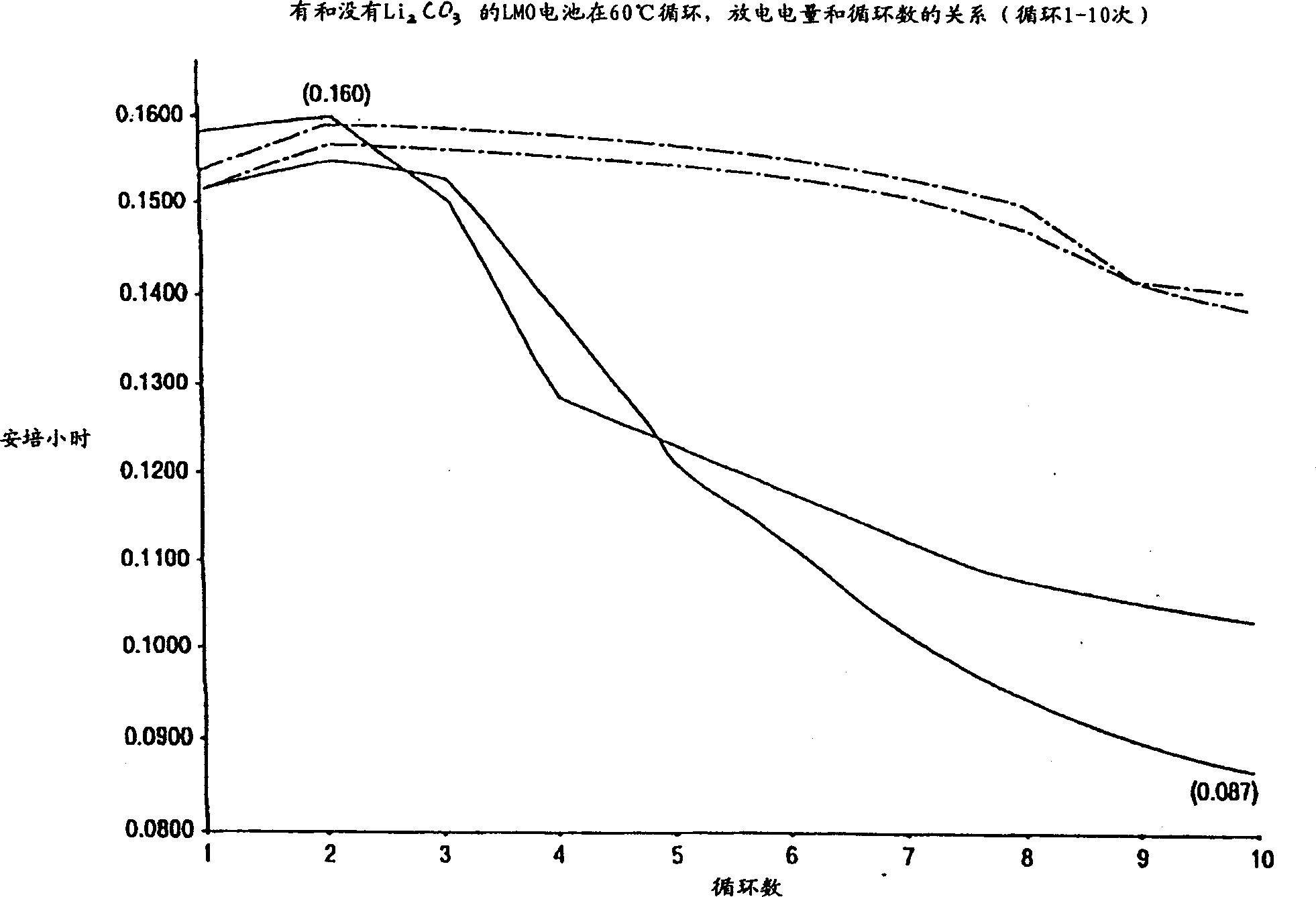

[0069] Example II: Treated LMO

[0070] Lithium manganese oxide spinel (LMO), a simple spinel whose specification is given in Table III, was obtained from Japan Energy Corporation as Japan Energy Corporation ISR 140B. The method of making all of the treated LMOs in some of the examples below included the following steps. The LMO and lithium carbonate were first mixed in a ball mill for 60 minutes. A small amount (1-2% by weight) of high-purity lithium carbonate particles with a particle size of about 5 microns is used. Such lithium carbonate is commercially available from Pacific Lithium, New Zealand. The use of large-sized ceramic ball milling media in the ball milling operation does not cause material abrasion. The medium is then removed from the mixture. Mixed Li 2 CO 3 / LMO was heated for 30 minutes in a box furnace set at 600-750°C. The treated material was removed from the furnace and immediately placed in a second chamber furnace set at 450°C for 1 hour. The fur...

Embodiment III

[0071] Example III: Use of cells treated with LMO

[0072] Solvent cast the paste containing MCMB2528 graphite, binder, plasticizer and casting solvent to manufacture graphite electrode. MCMB2528 is a mesoporous carbon microparticle supplied by Alumina Trading (Osaka Gas Company of Japan's US distributor) with a density of approximately 2.24 g / cm 3 ; at least 95% by weight of the particles have a maximum particle size of 37 microns, a median particle size of about 22.5 microns, and an interlayer distance of about 0.336. The binder is a copolymer of polyvinylidene fluoride (PVDF) and hexafluoropropylene (HFP), and the weight ratio of PVDF and HFP is 88:12. This adhesive is sold under the Kynar Flex trade name (indicating its registered trademark). Kynar Flex is commercially available from Atochem Corporation. Solvents are of electronic grade. The paste is cast on glass, and after the solvent evaporates, a self-supporting electrode is formed. The electrode composition was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com