Preparation method of TiO2 photocatalyst by loading TiO2 to diatomite formed in advance and doping rare earth

A rare earth doping and photocatalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, botanical equipment and methods, etc., can solve the problems of sunlight utilization limitation and photocatalytic reaction rate limitation, and achieve simple molding process , Excellent photocatalytic performance and stability, and the effect of improving photodegradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

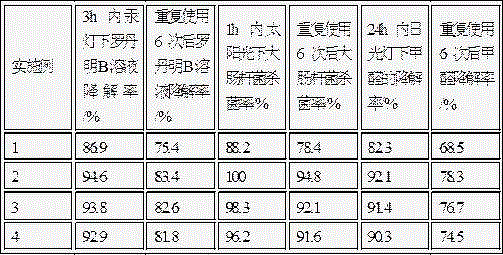

Examples

Embodiment 1

[0021] Example 1: First, weigh 20 g of diatomite, add 100 g of sulfuric acid with a mass fraction of 60%, pickle at 65°C for 95 minutes, filter with suction, dry and then calcinate at 500°C for 5 hours. Then take by weighing 10g of pretreated diatomite, add 0.3g dextrin, 0.2g hydroxypropyl methylcellulose, 0.4g sodium carbonate, 13ml deionized water, and use a multifunctional pelletizing machine to make diatomite Spherical, dry at 80°C for 4h, and calcined at 800°C for 2h. Finally, the titanium dioxide sol was prepared by sol-gel method; the spherical diatomite was put into the sol, soaked for 3 hours, dried, and calcined at 600°C for 2 hours to obtain the supported photocatalyst.

Embodiment 2

[0022] Example 2: First, weigh 20 g of diatomite, add 120 g of sulfuric acid with a mass fraction of 40%, pickle at 50°C for 75 minutes, filter with suction, dry and then calcinate at 600°C for 4 hours. Then weigh 10 g of pretreated diatomite, add 0.5 g of dextrin, 0.1 g of sodium carbonate, and 12 ml of deionized water, and use a multifunctional pellet machine to make the diatomite into a spherical shape, and dry it at 70 ° C for 6 hours. Calcined at 900°C for 2h. Finally, the rare earth cerium-doped titania sol was prepared by the sol-gel method, in which the doping amount of cerium was 0.5%; the spherical diatomite was put into the sol, dried for 2 hours after immersion, and calcined at 600 °C for 1.5 hours. A supported composite photocatalyst was obtained.

Embodiment 3

[0023] Example 3: First, weigh 20 g of diatomite, add 140 g of sulfuric acid with a mass fraction of 10%, pickle at 80°C for 30 minutes, filter with suction, dry and then calcinate at 300°C for 6 hours. Then take by weighing the diatomite after 10g pretreatment, add 0.3g hydroxypropyl methyl cellulose, 0.2g sodium carbonate, 11ml deionized water, adopt multi-function pelletizing machine to make diatomite spherical, at 60 Dry at ℃ for 12h, and calcined at 700℃ for 4h. Finally, the rare earth cerium-doped titania sol was prepared by sol-gel method, in which the doping amount of cerium was 0.3%; the spherical diatomite was put into the sol, dried for 5 hours after immersion, and calcined at 700°C for 1 hour to obtain Supported composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com