Attapulgite/graphite phase carbon nitride composite material and preparation method thereof

A graphite phase carbon nitride, attapulgite technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the difficulty of recycling, restrict the industrial application of catalysts, and difficult to separate catalyst powders, etc. problems, to achieve the effect of uniform load, high industrial promotion value, and large application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Preparation of modified graphitic carbon nitride:

[0024] Take dicyandiamide and a semi-closed alumina crucible, put it into a muffle furnace and heat it up to 500-700°C, keep it warm for 4-8 hours to obtain graphite phase carbon nitride; take the above graphite phase carbon nitride, add to Stirring in hydrochloric acid with a concentration of 8-12 mol / L for 10-20 hours, drying at 50-100 DEG C after washing to obtain modified graphite phase carbon nitride.

Embodiment 1

[0026] First, disperse 2.5g of the modified graphitic carbon nitride in 75ml of deionized water evenly in a constant temperature water bath at 40°C and stir for 1h as component A; add another 0.5g of attapulgite to 25mL of deionized water and stir for 30min, As component B; slowly drop component B into component A under continuous stirring conditions, continue to stir for 1 hour, transfer the mixed solution into a reaction kettle and keep warm at 150°C for 6 hours, centrifuge and dry to obtain attapulgite Supported graphitic phase carbon nitride composites.

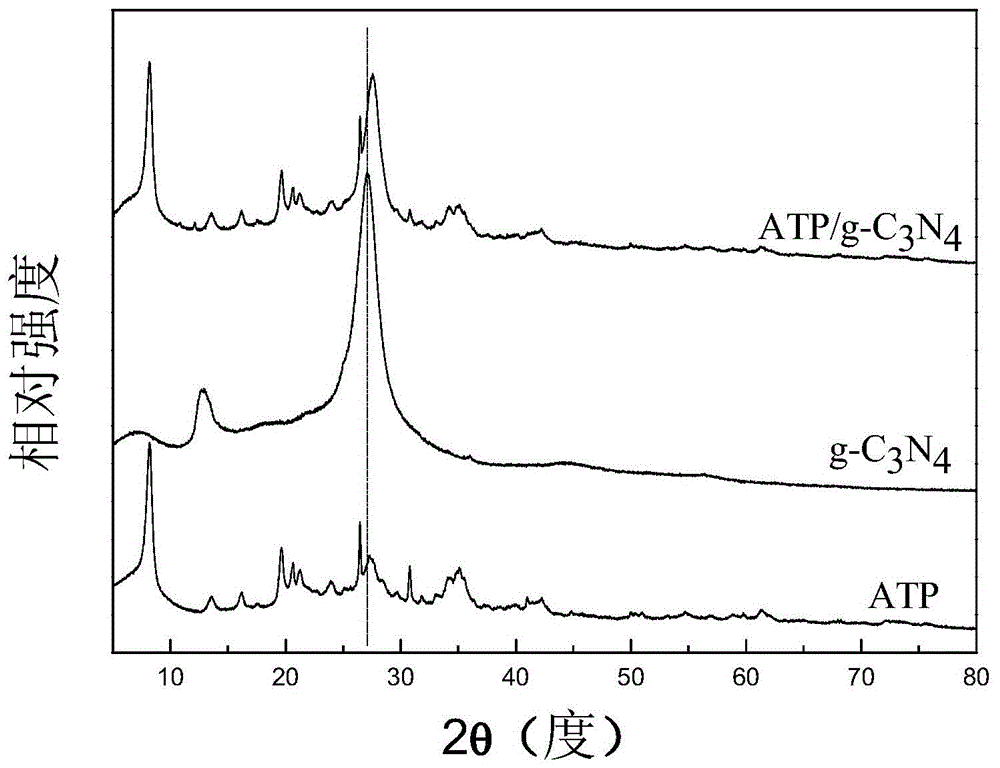

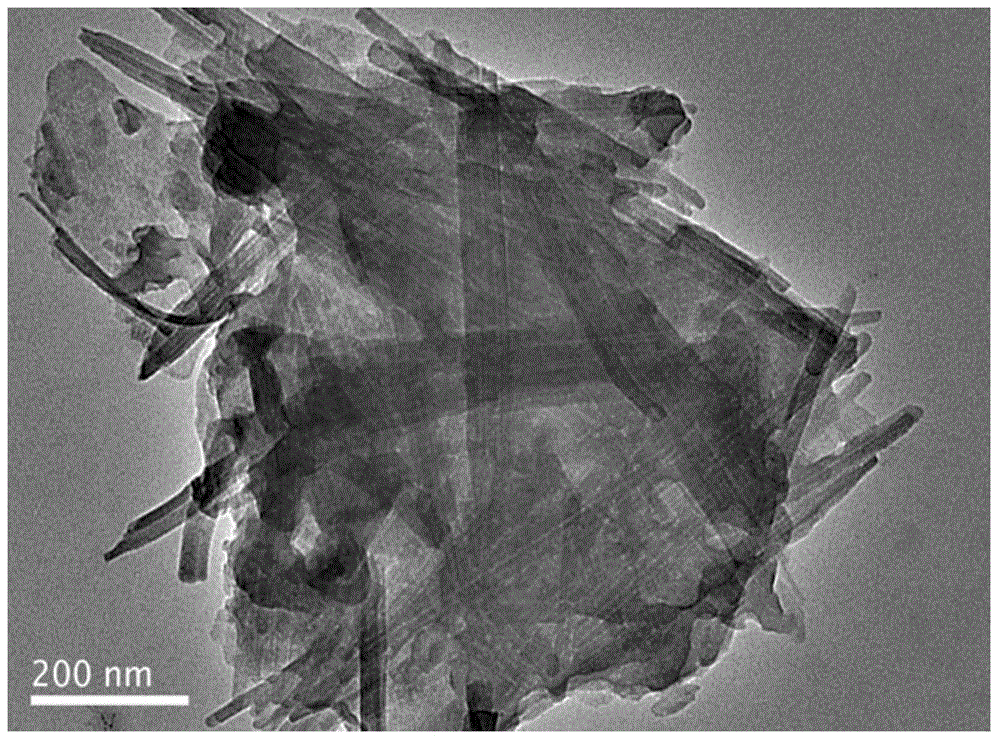

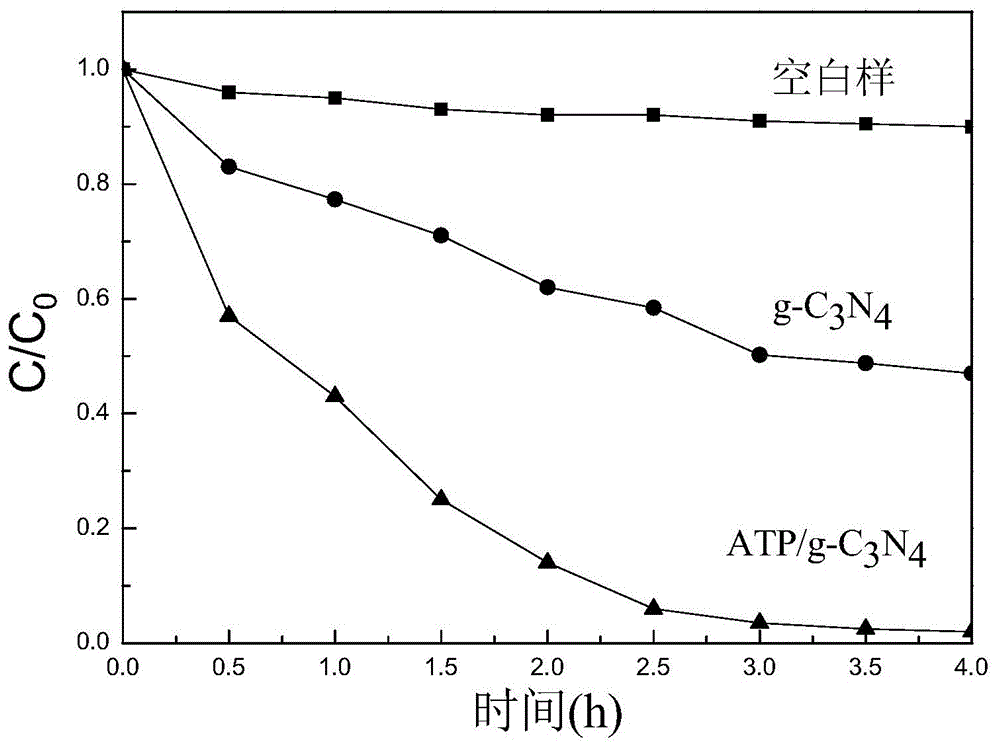

[0027] The X-ray powder diffraction experiment was carried out on the obtained sample, and its morphology and structure were observed under a transmission electron microscope. The attapulgite-loaded graphite phase carbon nitride prepared according to the process parameters of Example 1 was nitrided with attapulgite and graphite phase. Carbon XRD comparison patterns such as figure 1 shown. There are characteristic diffra...

Embodiment 2

[0035] Change the amount of acid-modified graphite phase carbon nitride to 3g, dissolve in 60ml deionized water and stir for 1h, add 0.8g of attapulgite to 40ml of deionized water and stir for 30min, slowly add the suspension of attapulgite Put into the suspension of graphite phase carbon nitride and stir for 1h, hydrothermally react at 200°C for 4h, centrifuge and dry to obtain ATP / g-C 3 N 4 composite material. The test of photocatalytic degradation activity is as embodiment 1, obtains ATP / g-C 3 N 4 The lowest C / C of the sample to methylene blue 0 reached 0.03.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com