Waste carbon fiber reinforced nylon 6 composite material and preparation method thereof

A technology of composite materials and carbon fiber, which is applied in the field of polymer materials, can solve the problems of high price of carbon fiber and achieve the effects of difficult recycling, simple processing method and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

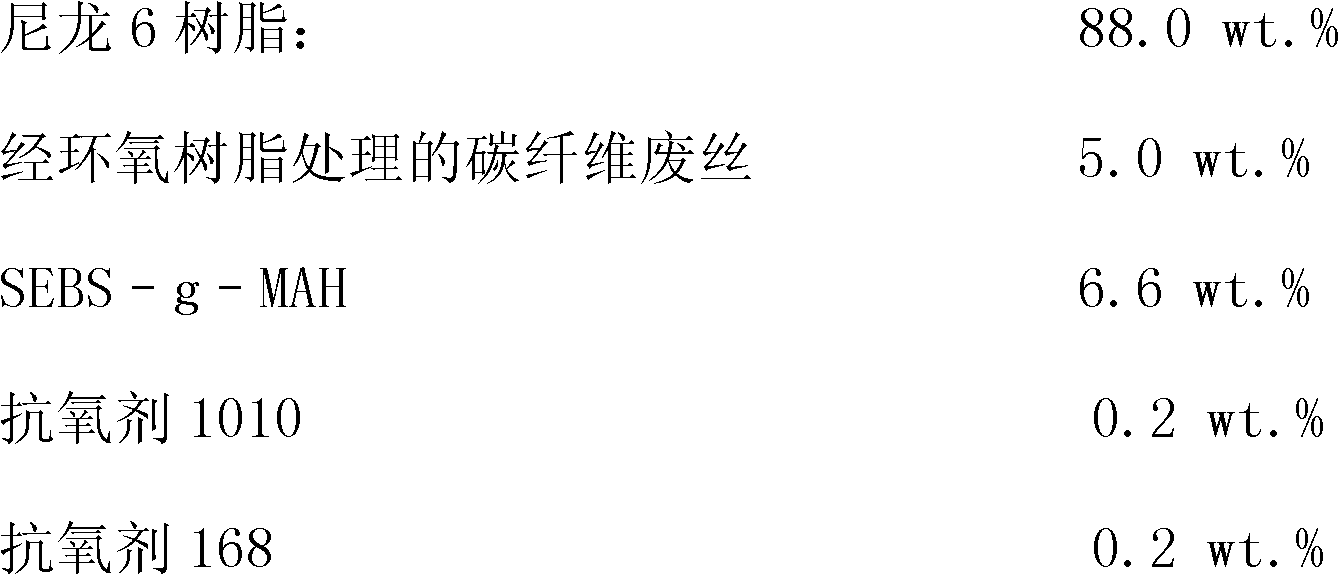

[0024] First, put carbon fiber waste silk in a bisphenol A epoxy resin / acetone solution with a mass percentage of 30wt.% and stir for 1 hour, then place it in a vacuum oven at 70°C to fully dry, completely volatilize the acetone, and make the epoxy resin adhere on carbon fiber waste. Then, take by weighing nylon 6 resin, carbon fiber waste silk, toughening agent and antioxidant by following mass percentage:

[0025]

[0026] Nylon 6 resin, SEBS-g-MAH, antioxidant 1010 and antioxidant 168 were placed in a high-speed mixer and mixed evenly, and then the mixed pellets were added from the hopper located at the rear end of the twin-screw extruder barrel. At the same time, the carbon fiber waste after surface treatment is fed from the side feeding port in the middle of the barrel through the side feeding device equipped with a weight loss weighing scale, and the vacuum pump at the end of the twin-screw extruder is turned on. The temperature from each section of the screw to the ...

example 2

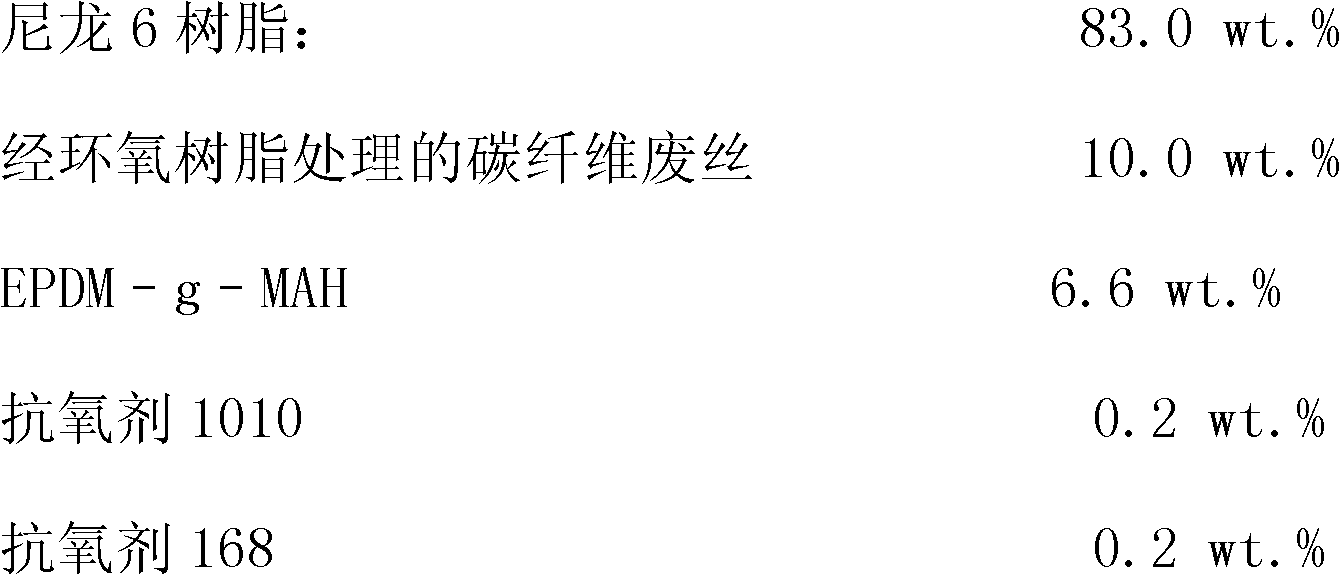

[0028] First, put carbon fiber waste silk in a bisphenol A epoxy resin / acetone solution with a mass percentage of 30wt.% and stir for 1 hour, then place it in a vacuum oven at 70°C to fully dry, completely volatilize the acetone, and make the epoxy resin adhere on carbon fiber waste. Then, take by weighing nylon 6 resin, carbon fiber waste silk, toughening agent and antioxidant by following mass percentage:

[0029]

[0030] Put nylon 6 resin, EPDM-g-MAH, antioxidant 1010 and antioxidant 168 in a high-speed mixer and mix evenly, and then add the mixed pellets from the hopper at the rear end of the twin-screw extruder barrel. At the same time, the carbon fiber waste after surface treatment is fed from the side feeding port in the middle of the barrel through the side feeding device equipped with a weight loss weighing scale, and the vacuum pump at the end of the twin-screw extruder is turned on. The temperature from each section of the screw to the machine head is 245, 250,...

example 3

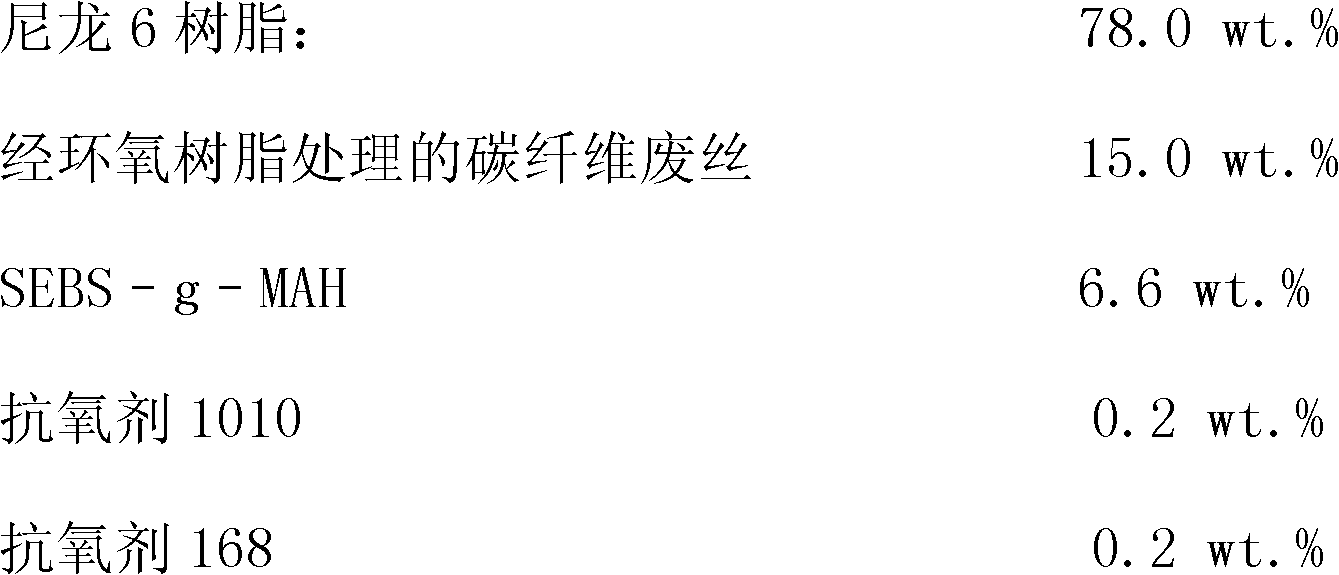

[0032] First, put carbon fiber waste silk in a bisphenol A epoxy resin / acetone solution with a mass percentage of 30wt.% and stir for 1 hour, then place it in a vacuum oven at 70°C to fully dry, completely volatilize the acetone, and make the epoxy resin adhere on carbon fiber waste. Then, take by weighing nylon 6 resin, carbon fiber waste silk, toughening agent and antioxidant by following mass percentage:

[0033]

[0034] Nylon 6 resin, SEBS-g-MAH, antioxidant 1010 and antioxidant 168 were placed in a high-speed mixer and mixed evenly, and then the mixed pellets were added from the hopper located at the rear end of the twin-screw extruder barrel. At the same time, the carbon fiber waste after surface treatment is fed from the side feeding port in the middle of the barrel through the side feeding device equipped with a weight loss weighing scale, and the vacuum pump at the end of the twin-screw extruder is turned on. The temperature from each section of the screw to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com