Composite material having visible-light catalytic activity and preparation method thereof

A technology of catalytic activity and composite materials, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. , band gap width and other issues, to achieve the effect of solving the difficulty of recycling, enhancing adsorption performance, and enhancing the degree of response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

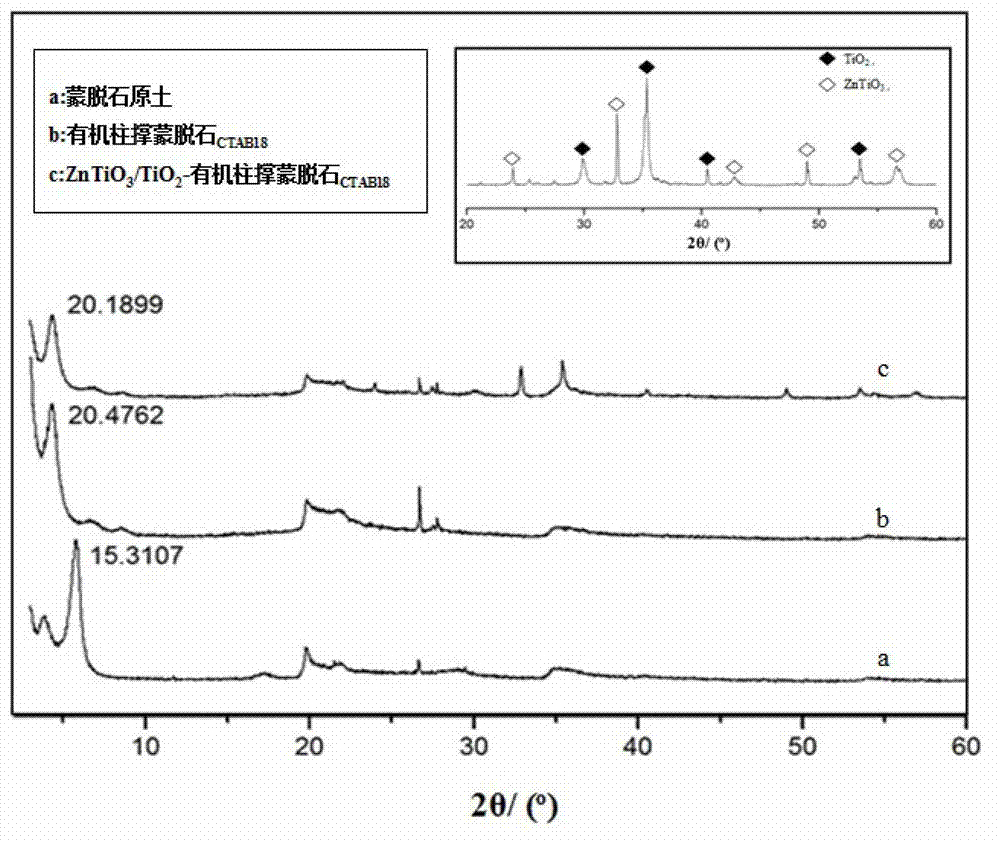

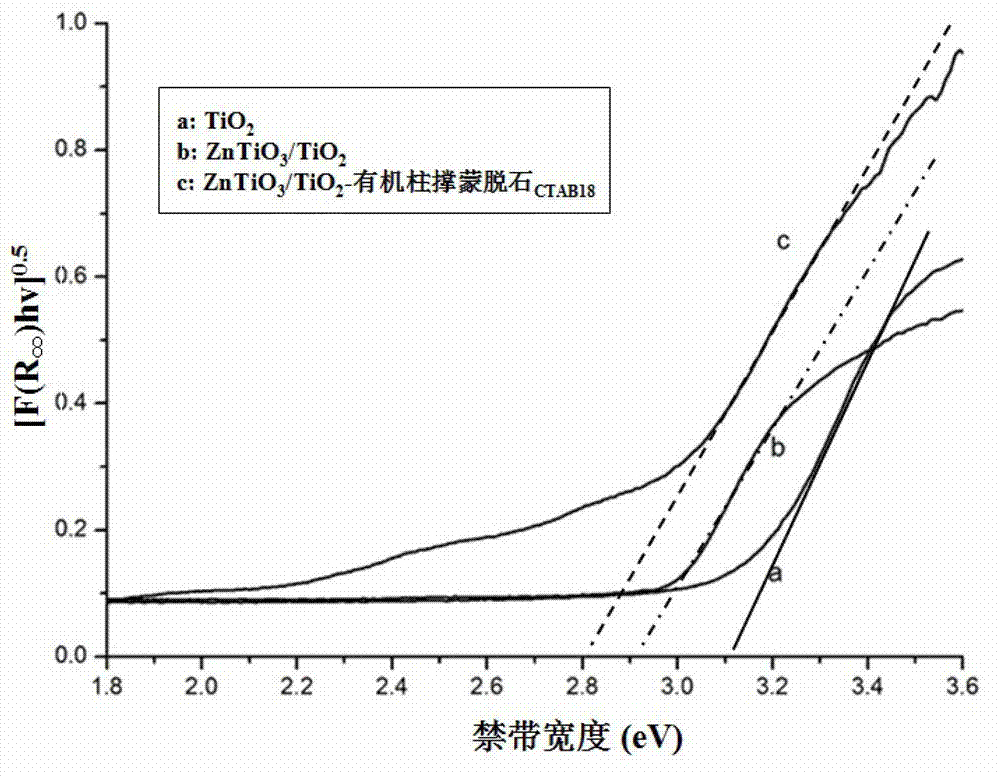

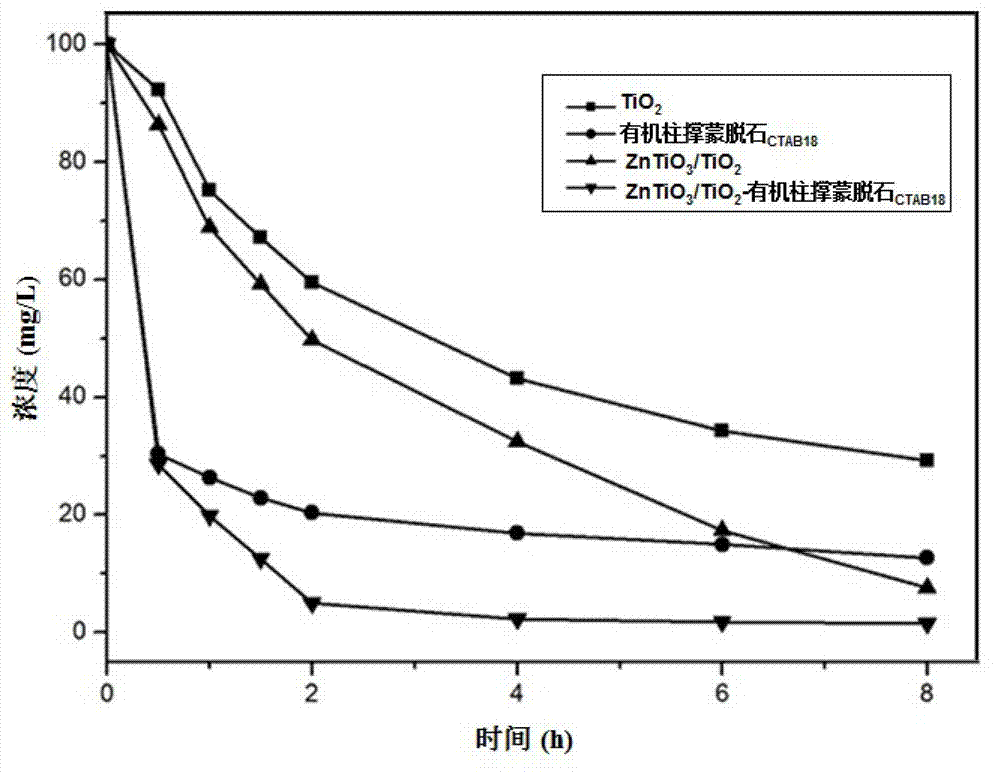

[0028] Example 1ZnTiO 3 / TiO 2 -organic pillared montmorillonite CTAB18

[0029] (1) Organic pillared montmorillonite CTAB18: The montmorillonite mineral is crushed and passed through a 200-mesh sieve, placed in a drying oven at 60°C and dried for 2 days, which is the original montmorillonite soil; 20 parts by weight of the original montmorillonite soil are mixed according to the ratio of the original montmorillonite soil and distilled water. The mass ratio is 1:10, and the original soil is dispersed in water to form a suspension slurry; then, octadecyltrimethylammonium bromide ( CTAB18), stirred in a water bath at 60°C for 2 hours, and left overnight. The product was washed with deionized water to be free of Br - (in Ag + test) exists, dried at 90°C, fully ground and passed through a 200-mesh sieve to obtain organic pillared montmorillonite CTAB18 .

[0030] (2) ZnTiO 3 / TiO 2 Preparation: molar ratio [Zn +2 ] / [Ti +4 ]=1 ratio, under magnetic stirring, 2.5g zinc a...

example 2

[0038] Example 2ZnTiO 3 / TiO 2 -organic pillared vermiculite CTAB12

[0039] (1) Organic pillared vermiculite CTAB12 : The vermiculite mineral is crushed and passed through a 200-mesh sieve, placed in an 80°C drying oven and dried for 1 day to become the original vermiculite soil; take 20 parts by weight of the original vermiculite soil, and the mass ratio of the original soil to distilled water is 1:10 Ratio, disperse the raw soil in water to form a suspension slurry; then add dodecyltrimethylammonium bromide (CTAB12) in an amount equivalent to twice the cation exchange capacity (CEC) of the vermiculite raw soil, in a water bath at 60°C Stir at constant temperature for 2h and leave overnight. The product was washed with deionized water to be free of Br - (in Ag + inspection) exists, dried at 90°C, fully ground and passed through a 200-mesh sieve to obtain organic pillared vermiculite CTAB12 .

[0040] (2) ZnTiO 3 / TiO 2 The preparation is as in step (2) in Example 1...

example 3

[0042] Example 3ZnTiO 3 / TiO 2 -organic pillared rectorite CTAB14

[0043] (1) Organic pillared rectorite CTAB14 : the rectorite mineral is passed through a 200-mesh sieve after being pulverized, placed in a 70°C drying oven and dried for 1.5 days, which is the original rectorite soil; get 20 parts by weight of the rectorite original soil, and the mass ratio of the original soil to distilled water is The ratio of 1:10, disperse the original soil in water to form a suspension slurry; then add tetradecyltrimethylammonium bromide (CTAB14) in an amount equivalent to 0.5 times the cation exchange capacity (CEC) of rectorite original soil, Stir for 2 h under the constant temperature condition of a water bath at 60° C., and let stand overnight. The product was washed with deionized water to be free of Br - (in Ag + test) exists, dried at 90°C, fully ground and passed through a 200-mesh sieve to obtain organic pillared rectorite CTAB14 .

[0044] (2) ZnTiO 3 / TiO 2 The prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com