Method and production equipment for variable-pressure distillation and purification of methyl acetate

A technology of methyl acetate and pressure swing rectification, applied in the chemical industry, can solve the problems of difficult solvent recovery, low product purity and high energy consumption, and achieve the effects of high product purity, high yield and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

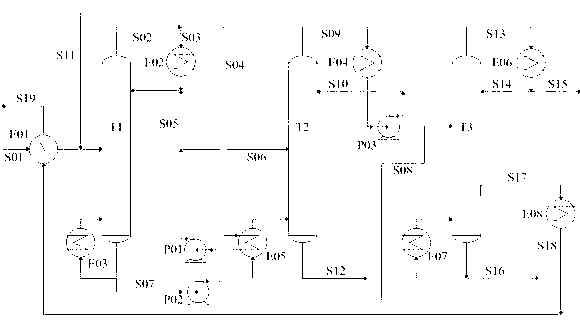

[0034] Attached figure 1 In the process flow shown, the feed flow rate is 3200kg / h, the feed temperature is 50°C, and the feed composition is: 96% methyl acetate, 0.2% methanol, 3.5% water, and 0.3% sec-butyl acetate. The body material of the pressurized distillation tower T1 is SUS304, the tower is filled with CY700 regular wire mesh corrugated packing, the number of theoretical plates is 40, and the 22nd block is fed. Operating conditions: operating pressure 0.4MPa, tower top temperature 93.2 ℃, tower bottom The temperature is 98.4°C, the reflux ratio is 1; the material of the atmospheric distillation column T2 is SUS304, and the column is filled with CY700 regular wire mesh corrugated packing, the number of theoretical plates is 36, and the 18th block is fed. Operating conditions: operating pressure 0.1MPa, The temperature at the top of the tower is 56.4°C, the temperature at the bottom of the tower is 57.5°C, and the reflux ratio is 1.5; the material of the methyl acetate ...

Embodiment 2

[0038] Attached figure 1 In the process flow shown, the feed flow rate is 1600kg / h, the feed temperature is 53°C, and the feed composition is: 91.2% methyl acetate, 3.1% methanol, 5.4% water, and 0.3% sec-butyl acetate. The body material of the pressurized distillation tower T1 is SUS304, the tower is filled with CY700 regular wire mesh corrugated packing, the number of theoretical plates is 38, and the 20th block is fed. The temperature is 99.8°C, the reflux ratio is 1; the body material of the atmospheric distillation column T2 is SUS304, and the column is filled with CY700 regular wire mesh corrugated packing, the number of theoretical plates is 36, and the 18th block is fed. Operating conditions: operating pressure 0.1MPa, The temperature at the top of the tower is 56.4°C, the temperature at the bottom of the tower is 57.5°C, and the reflux ratio is 1.5; the material of the methyl acetate refining tower T3 is SUS304, and the tower is filled with CY700 regular wire mesh cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com